A. The Suitable Application Range of 5 Axis 3000/6 Large Scale Plasma Oxy-fuel CNC Pipe Intersection Cutting Machine:

1. This model aims on cutting and making groove on large diameter pipes with comparatively short length (The longest is 6000mm);

2. The grooving capability in this 5 Axis model is same as 7 Axis 3000mm Large Scale CNC Pipe Cutting Machine;

Cutting and Beveling in Wuxi JACK 5 Axis/7 Axis 3000mm Large Scale Plasma Oxy-fuel CNC Pipe Intersecting Cut Machine: (Fig.1)

3. Meanwhile, 5 Axis Large Scale CNC Pipe Intersection Cutting Machine is recommended to be used for cutting workpiece pipes with similar diameters (Had better same diameter) within a work cycle. The next segment will have explanation on why we suggest this;

4. In a short, the 5 Axis 3000/6 Flame and Plasma Large Scale CNC Pipe Intersecting Cut Machine is another brother product of 5 Axis 3000/12 CNC Pipe Cutting Machine, with half of the valid pipe cutting length.

B. Why does it Important to Keep Small Change or No Change on Diameters of Pipe, for Running of the 5 Axis 3000/6 Large Scale Plasma Oxy-fuel CNC Pipe Cutting Machine?

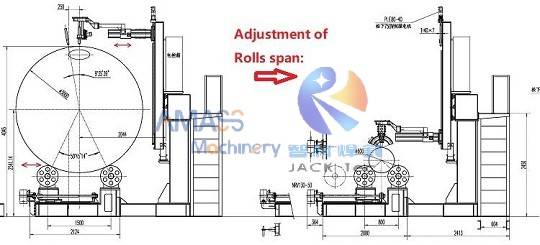

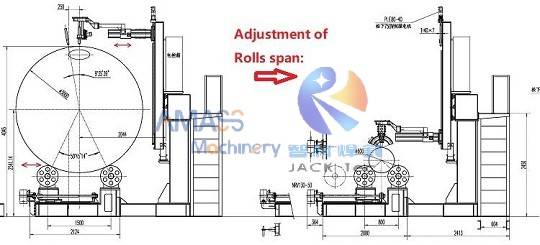

1. The below illustration gives graphic explain on pipe diameter change and corresponding roller span change, in Large Scale CNC Pipe Intersection Cutting Machine: (Fig.2)

2. As can be observed from the above, in 5 Axis CNC Pipe Cutting Machine, for the large diameter pipe of up to Φ3000mm, without:

1) V Axis for controlling cutting torch lateral movement;

2) And W Axis for controlling turning rolls moved along radial direction of pipe;

3. It is relative difficult to for the CNC Pipe Intersection Cutting Machine to control cutting position in this direction, which is fitting for various diameters of pipe, especially switching among pipes with diameter wide change. For example, the CNC Pipe Intersecting Cut Machine first cut a pipe of Φ1000mm diameter, then cut a pipe of Φ3000mm diameter.

C. Mechanical Structures in Substitutes of V Axis and W Axis in 5 Axis 3000mm Large Scale CNC Pipe Intersection Cutting Machine:

When it is necessary to switch among workpiece pipes, there should have some adjustment job in CNC Pipe Cutting Machine:

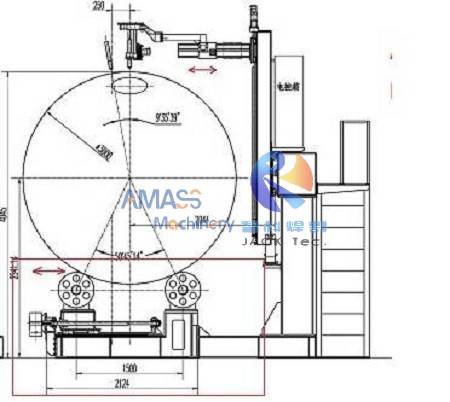

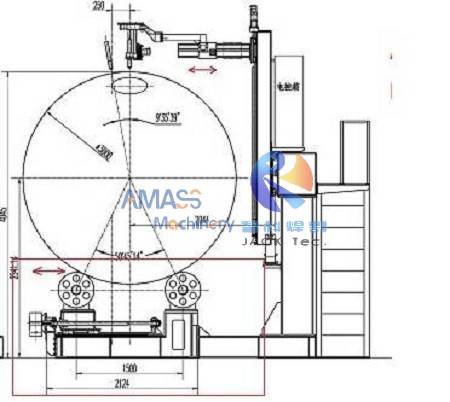

1. Span of the 2 sets of turning rolls supporting the pipe need to be adjusted by means of bolt: (Fig.3)

In mechanical frame of CNC Pipe Intersection Cutting Machine, the supporting bed consist of turning rolls is made into 2 grades of 0~1500m as well as 1500~ 3000mm, which is switched with bolts;

2. As to the extension distance of cutting torch along radial direction of pipe, same as that of turning rolls, it is also made into 2 grades of stationary respectively.

The 2 arrays of supporting turning rolls in Wuxi JACK 5 Axis/7 Axis Large Scale CNC Pipe Intersection Cutting Machine: (Fig.4)

3. In all, the 5 Axis 3000mm series Large Scale CNC Pipe Intersecting Cut Machine is more applicable for cutting and beveling large pipes of consistent diameter, or at least no great difference;

4. For customers who need to process pipes with diameter from as small as Φ600mm to as large as Φ3000mm, for the purpose of convenient operation and precise control on the CNC Pipe Cutting Machine, the 7 Axis Large Scale CNC Pipe Intersecting Cut Machine is more suitable choice.

D. Technical Parameters of 5 Axis 3000/6 Large Scale Plasma Oxy-fuel CNC Pipe Cutting Machine:

Below is specification of 5 Axis 3000/6 Flame and Plasma Large Scale CNC Pipe Intersecting Cut Machine:

Model Technical Parameter | 5 Axis CNC-CP 3000/6 Large Scale Plasma Oxy-fuel CNC Pipe Intersection Cutting Machine |

Pipe Diameter Range (mm) | 600 ~ 3000 |

Max. Pipe Length (mm) | 6000 |

Pipe Thickness (mm) | 6~100 mm for flame cutting 3 ~ 25mm for plasma cutting |

Cutting Speed | 200∼800mm/min. for flame cutting Around 200~ 2000mm/min. for plasma cutting (Based on thickness of Pipe and Plasma Power) |

CNC Control Axis | 5 Axis of X/Y/Z/A/B X Axis: For positioning along pipe length direction; Y Axis: For controlling pipe revolving; Z Axis: Fitting for pipe diameter change; A Axis: For managing cutting torch tilt along pipe radius; B Axis: For managing cutting torch tilt along pipe length |