A. The Function and Origin of 5 Axis Flame Plasma Large CNC Pipe Intersection Cutting Machine:

1. The 5 Axis 3000/9 model in this section is sibling product of 5 Axis 3000/12 Flame and Plasma Large CNC Pipe Cutting Machine, with 3000mm shorter travel stroke of cutting torch along pipe axial direction;

2. In other words, the key technical parameters in 5 Axis 3000/9 Flame Plasma Large CNC Pipe Intersection Cut Machine are as below:

1) Workpiece Diameter: Pipe diameter covering small to medium to large size, up to Φ3000mm;

2) Workpiece Length: Max. available cutting length is 9000mm, for 1 piece of pipe;

3) Control Axis and Ability: With 5 Axis control (X/Y/Z/A/B) in this CNC Pipe Cutting Machine, oblique chamfering can be cut together with cut off within one time stroke of cutting torch;

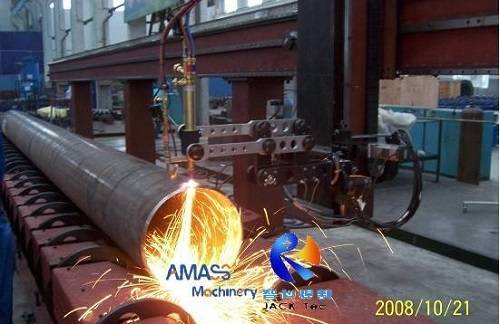

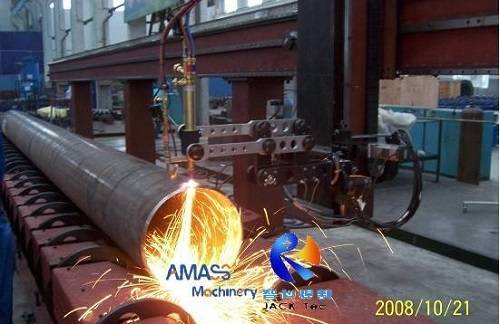

Large diameter and thick wall pipe cut with slant beveling, in Wuxi JACK 5 Axis 3000/9 Large Flame Plasma CNC Pipe Cutting Machine: (Fig.1)

B. The Classification and Corresponding Models of Flame Plasma Large CNC Pipe Cutting Machine:

1. As can be seen from the first segment, in product family of CP series Flame Plasma CNC Pipe Intersection Cutting Machine, the distinction among models is based on 3 critical specifications of:

1) Control Axis: There are variations of 3 Axis/ 5 Axis/ 6 Axis/ 7 Axis in CNC Pipe Cutting Machine, rendering capabilities from basic cut off and straight edge hole, to complicated beveling of various forms;

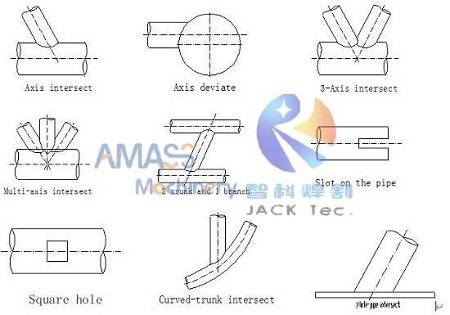

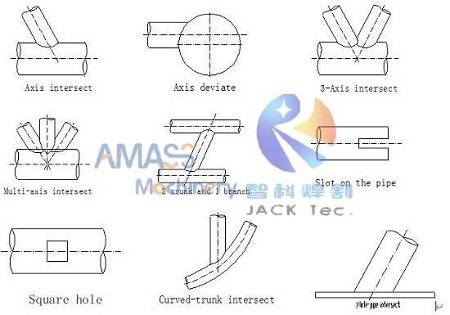

The 9 standard and common adopted grooves available from Wuxi JACK 5 Axis/6 Axis/ 7 Axis CNC Pipe Intersection Cut Machine: (Fig.2)

2) Pipe Length: There are variations in “/12m/9m/6m”; The reason why we have such partition on model of the CNC Pipe Cutting Machine, is mainly considered for best cost effectiveness. Please check product section of “7 Axis 3000/6 Heavy duty Full Function CNC Pipe Intersection Cutting Machine”;

3) Pipe Diameter: There are variations of “3000mm/ 1400mm/ 600mm/2000mm/2500mm” in CNC Pipe Cutting Machine. Of which, the specifications of “2000mm/ 2500mm” were developed following “3000mm/ 1400mm/ 600mm”;

Varying diameters of pipe from Φ80mm to Φ3000mm can all be cut and edge grooved in Wuxi JACK CNC Pipe Intersection Cutting Machine: (Fig.3)

C. So, why there are so much models of partition on Wuxi JACK CP series CNC Pipe Intersection Cut Machine?

1. The reason lies behind such degree of segmentation is: The CNC Pipe Cutting Machine is a very sophisticated equipment, which involves industrial computer, programming software, communication between hardware and software, cutting system (Oxy fuel and or plasma), etc.;

2. Of which even for standard model of the CNC Pipe Intersection Cutting Machine, it is impossible to devise a “one-fit-for-all” model of the CNC Pipe Cutting Machine, to meet specific demands from all customers;

3. And, even if such unique one model of CNC Pipe Cutting Machine exists, it will not be a cost effective solution for many customers:

1) For example, the model of 5 Axis 3000/9 Flame Plasma Large CNC Pipe Intersection Cutting Machine is for cutting medium to large pipes, with max. 9m length and diameter of Φ3000mm;

2) If customer chooses the “/12” model of CNC Pipe Cutting Machine, this customer will spend unnecessary more money, paying for the extra 3m length of workpiece friction roller group and mechanical frame;

3) Besides, considering the special control principle in CNC Pipe Intersection Cutting Machine, it is not recommended to cut 2 or more pieces of pipes together. Instead, there should be one piece of pipe to be cut in the CNC Pipe Cutting Machine at one time;

4) This is why the “/12” model CNC Pipe Cutting Machine is not suitable for customers whose workpieces pipe have max. 9m length;

4. Finally, as summary, besides the above-mentioned standard models, Wuxi JACK can design and manufacture CNC Pipe Intersection Cutting Machine with special size and specifications for customers, who has demand outside the range of standard model CNC Pipe Cutting Machine can cover.

D. Technical Parameters of 5 Axis 3000/9 Flame Plasma Large CNC Pipe Cutting Machine:

Below is specification of 5 Axis 3000/9 Flame and Plasma Heavy Duty CNC Pipe Intersection Cut Machine:

Model Technical Parameter | 5 Axis CNC-CP 3000/9 Flame Plasma Large CNC Pipe Intersection Cutting Machine |

Available Diameter Range of Pipe for Cutting and Grooving | 600 ~ 3000 (mm) |

Available Max. Length of Pipe for Cutting and Grooving | 9000 (mm) |

Available Thickness of Pipe for Cutting and Grooving (mm) | 6~100 mm for flame cutting; 3 ~ 25mm for plasma cutting |

Available Cutting Speed | 200∼800mm/min. for flame cutting Around 200~ 2000mm/min. for plasma cutting (Based on thickness of Pipe and Plasma Power) |

CNC Control Axis | 5 Axis of X/Y/Z/A/B X Axis: For positioning along pipe length direction; Y Axis: For controlling pipe revolving; Z Axis: Fitting for pipe diameter change; A Axis: For managing cutting torch tilt along pipe radius; B Axis: For managing cutting torch tilt along pipe length |