Purpose of this Blog on Flame Plasma CNC Pipe Cutting Machine:

This blog aims on helping readers having a quick understanding and general idea on Wuxi JACK designed and produced CNC Pipe Intersection Cutting Machine:

1) The Importance and Wide Application of the machine;

2) Evolvement of the machine;

3) How to Select Proper Model of the machine;

4) Wuxi JACK Technical Strength on the machine

A. The Importance and Wide Application of CNC Pipe Cutting Machine:

1. CNC Pipe Cutting Machine, the other name is CNC Pipe Intersection Cutting Machine, is a kind of important pipe machining equipment, which has very extensive application across manufacturing industries;

2. Over the past decades, CNC Pipe Flame Plasma Cutting Machine has witnessed rapid development and growth in terms of technical complexity, and applicating volume. Currently, there are 3 axis/ 5 axis/ 6 axis/ 7 Axis models machine available for selection, covering the pipe diameter ranging from Φ48mm to Φ3000mm;

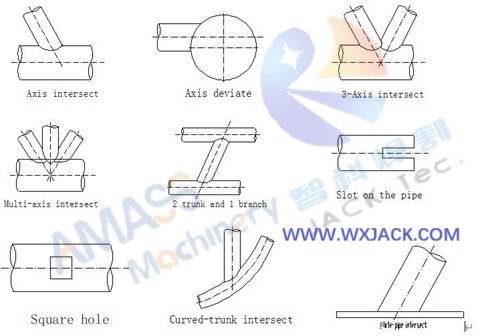

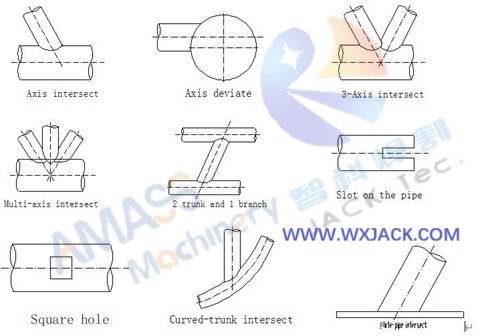

1) List of Classical Pipe Cutting Kerfs for Intersection Connection, available from 6 Axis/7 Axis/ 5 Axis CNC Pipe Cutting Machine: (Fig.1)

2) Large size Φ3000mm carbob steel pipe with holes, being cut from Wuxi JACK 7 Axis CNC Pipe Cutting Machine: (Fig.2)

3) The Pipes with intersecting cutting kerfs and subsequent intersection connections, produced from Wuxi JACK different control axis CNC Steel Pipe Intersection Cutting Machine: (Fig.3)

3. More Select on Machine Model: With more and more customers choose CNC Steel Pipe Cutting Machine as their production equipment, how to select proper model/ specification/ configuration of this equipment, to get the optimum solution meeting targets of best quality/ productivity/ operation/ cost effective becomes more and more important;

4. From perspective of machine supplier, this blog will have a brief introduction on development history of CP series Flame Plasma CNC Pipe Cutting Machine, its technical characteristics of each configuration, as well as applicable application. Hope it will be a little assistance for customers who have interest on this power function equipment of the CNC control machine for high effective and quality pipe cutting.

B. Evolvement of CNC Pipe Cutting Machine:

1. Initiation: 3 Axis CNC Pipe Cutting Machine:

1) The CNC machine for metal pipe cutting starts from 3 axis control, for severing fixed length of pipe, and cutting holes. The cutting kerfs are of straight edge;

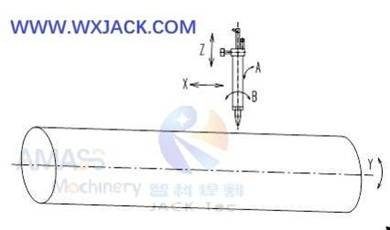

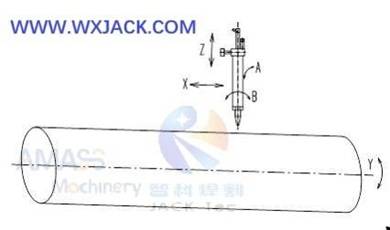

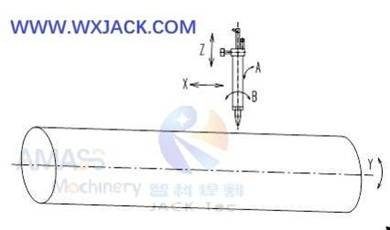

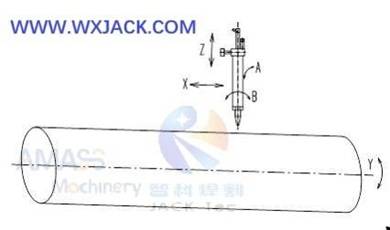

a) The illustration on X/ Y /Z Axis in 3 Axis CNC Pipe Cutting Machine: (Fig.4)

b) The illustration on thermal cutting torch in 3 Axis CNC Pipe Cutting Machine: (Fig.5)

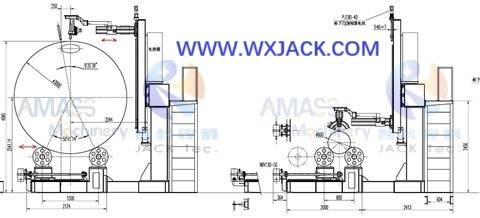

c) Wuxi JACK Φ600mm/12 model 3 Axis CNC Steel Pipe Cutting Machine: (Fig.6)

2) Applicable Application of 3 Axis CNC Pipe Cutting Machine:

Here we stress that, with mature on more sophisticated product of 5 Axis/ 6 Axis/ 7 Axis machine, the earliest model of CP3- 600~660 series 3 Axis machine still has its position in market:

a) 3 Axis CNC Pipe Cutting Machine is applicable for small diameter and thin wall workpieces: The diameter usually does not exceed Φ660mm, and thickness of pipe wall is less than 10mm;

b) For the above specification of workpieces, 3 Axis machine has the advantage of cost effectiveness.

2. Development for Slant Angle Beveling Cut: 5 Axis CNC Pipe Cutting Machine:

1) Why Need Pipe Edge Groove: With growing thicker of pipe wall, pipe cutting needs to have slant edge cutting kerf, so that the next step of intersection connection can be made with eligible quality;

2) New Degree of Freedom: Correspondingly, cutting torch in CNC Pipe Intersection Cutting Machine should be able to swing along pipe length and radial direction, in the scope of ±45°~ ±50°, shown as A axis and B axis in below sketch:

Control axis of 5 Axis CNC Pipe Cutting Machine: (Fig.7)

a) Cutting torch tilting for edge beveling, in Wuxi JACK 5 axis CNC Steel Pipe Intersection Cutting Machine: (Fig.8)

b) The elliptical through hole with oblique edge cutting kerf, produced from Wuxi JACK 5 Axis machine: (Fig.9)

3) Application of 5 Axis CNC Pipe Cutting Machine:

5 CNC control axis model machine is suitable for processing on medium range pipe diameter. The typical specification is Φ1400mm, thickness 3mm~ 60mm.

3. Expanded to Large Diameter Pipe Beveling Cut: 6 Axis CNC Pipe Cutting Machine:

With powerful ability of perfect slant beveling, 5 Axis model machine has its restriction on diameter of pipes for best quality cutting:

1) Applicable Pipe Diameters: When diameter of pipe growing bigger than Φ2000mm, Additional V axis should be adopted in the CNC Pipe Cutting Machine, so that cutting torch can move along pipe radius direction;

2) In this way, larger diameter of pipes can be taken care properly with 6 CNC control axis machine;

The V axis indication in 6 Axis CNC Pipe Cutting Machine: (Fig.10)

3) Application of 6 Axis CNC Pipe Flame Plasma Cutting Machine:

6 CNC control axis model machine is suitable for steel pipes with diameter exceeding Φ2000mm, thickness 3mm~ 100mm.

4. Fitting for Super Large Pipe Cutting and Beveling: 7 Axis CNC Pipe Cutting Machine:

1) Yes, with the technological development, CNC Pipe Flame Plasma Cutting Machine is also applied for cutting and chamfering on super large steel pipes with diameter Φ2500mm to Φ3000mm;

2) By this time, the 7th W axis should be used in the machine, for moving pipe supporting and revolving unit transversely. In this way, cutting torch can reach the whole range of workpiece diameter;

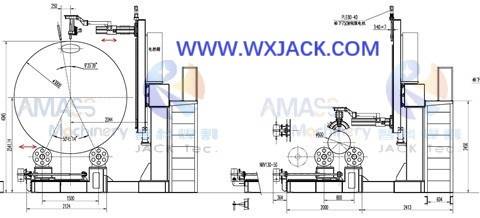

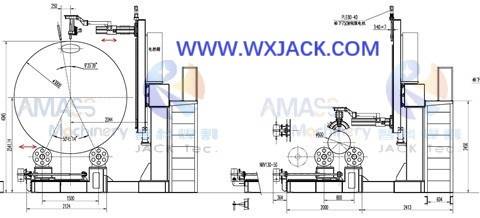

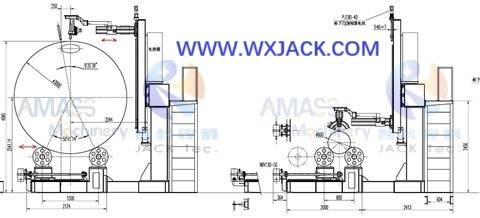

a) The W axis indication in 7 Axis CNC Pipe Cutting Machine: (Fig.11)

b) Wuxi JACK Exported to America CP7-3000/12 model Large 7 Axis CNC Pipe Cutting Machine: (Fig.12)

C. How to Select Proper Model of CNC Pipe Intersection Cutting Machine:

1. We have discussed proper workpiece specifications fitting for each configuration of the machine. As a quick review:

2. 2 Key Factors Determining Proper Model of CNC Pipe Flame Plasma Cutting Machine:

This can be summarized as:

1) The largest diameter of workpiece;

2) Slant beveling requirement:

1) When customers only need to cut small diameter pipes (Less than Φ1000mm, thickness up to 10mm), without further requirement on oblique chamfer, 3 Axis model machine is a good choice;

2) When diameter of pipes grows to medium level (Φ1000mm to Φ2000mm, and thickness of pipe also grow bigger (Up to 60mm), customer should select 5 Axis model machine;

3) When diameter of pipe is larger than Φ2000mm, (Thickness up to 100mm), then at least 6 Axis large CNC Pipe Cutting Machine should be chosen;

4) Especially for pipes with diameter in the range of Φ2500mm to Φ3000mm, (Thickness up to 100mm), heavy duty large scale CNC 7 Axis Pipe Cutting Machine is the most proper model for customers.

D. Wuxi JACK Technical Strength on Flame Plasma CNC Pipe Cutting Machine:

Wuxi JACK is the first company in the industry, to successfully develop and manufacture the 7 Axis large CNC Pipe Cutting Machine for workpiece diameter up to Φ3000mm:

1. The difficulty on producing such super large CNC machine for pipe intersection cutting, not only involves sophisticated control software and hardware integration, but also delicate and ingenious design on its mechanical system;

2. As we know, CNC machine is usually applied in the field of small to medium level of servo motor power, less than 1 kW;

3. For bigger and heavier workpiece as well as corresponding mechanical frame, precise and accurate management is really a challenge, which utilizes servo motor of 4 ~ 5kW, for workpiece as heavy as 50 Ton;

4. Precision: The CP7 3000/12 heavy duty large scale 7 Axis CNC Pipe Cutting Machine produced by Wuxi JACK has precision of ±0.35mm, in every axis for such large workpiece (Φ3000mm, 12m long, 50 Ton), which is truly a world class top grade CNC Pipe Cutting Machine, and has gained high recognition from customers.