1. Outline on Usage and Advantage of 5 Axis 3000/12 Large Scale Plasma Flame CNC Pipe Cutting Machine:

1) Application Characteristics: The 5 Axis 3000/12 Flame and Plasma Large Scale CNC Pipe Cutting Machine is one of the large scale models in the product group of CNC Pipe Intersection Cutting Machine, and one of the most often selected model;

2) Advantages of CNC-CP3000/12 Model 5 axis Plasma Flame CNC Pipe Cutting Machine:

a) Applicable Pipe Diameter: Technical specifications of 3000/12 CNC Pipe Intersection Cutting Machine covers the widest range of workpiece diameter: From the minimum Φ600mm to the largest Φ3000mm;

b) CNC Control and Capability: And with the 5 axis control in this advanced CNC Pipe Cutting Equipment, most majority of customers demand on pipe cutting, including cut off and beveling, can be met in practical application;

3) Working Capability of CNC-CP3000/12 Model 5 Axis Plasma Flame CNC Pipe Intersection Cutting Machine:

a) Max. Pipe Size: This Large Scale CNC Pipe Cutting Equipment can cut out and make beveling on workpieces pipes/ tubes with length up to 12m, and diameter up to 3000 mm;

b) Functions: Both cutting off, and chamfering on edges of various types on pipes are available;

4) Cutting kerfs Produced from Wuxi JACK 5 Axis CNC Pipe Cutting Machine: (Fig.1)

2. Working Features of 5 Axis 3000/12 Large Scale Plasma Flame CNC Pipe Intersection Cutting Machine:

1) Cutting Technology in CNC-CP series CNC Pipe Cutting Machine is similar to that of the CNC Plate Strip Cutting Machine, which is adopted with Oxy-fuel for cutting thick wall pipes, and plasma for cutting thin to medium thickness pipes;

2) CNC Control Axis: Also controlled with numerical control system, this powerful CNC Pipe Cutting Machine has much more control axis: 5 axis compared with 2 axis;

3) Workpiece Pipe Support: During working of the CNC Pipe Intersection Cutting Machine, the large diameter workpiece rotates slowly along with progress of cutting process, as shown in the attached 5th and 6th photos. This means, its supporting rollers work like a group of Welding Turning Roller.

3. The Distribution and Function of 5 Axis in Large Scale Plasma Flame CNC Pipe Intersection Cutting Machine:

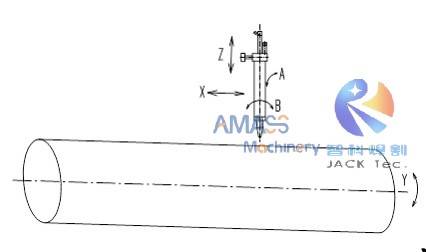

1) For the 5 Axis controlled with Wuxi JACK Large Scale CNC Pipe Intersection Cutting Machine, please check below sketch: (Fig.2)

2) Meaning of the 5 Axis in the CNC Pipe Cutting Machine:

a) Swing of Cutting Torch along Pipe Radial Direction: A Axis (Perpendicular to screen)

b) Swing of Cutting Torch along Pipe Axial Direction: B Axis (Parallel to screen)

c) Movement of Cutting torch along Pipe Axial Direction: X Axis

d) Movement of Cutting Torch along Vertical Direction: Z Axis

e) Rotation of Pipe: Y Axis

4. Technical Parameters of 5 Axis CNC-CP 3000/12 Large Scale Plasma Flame CNC Pipe Intersection Cutting Machine:

Below is specification of the 5 Axis CNC-CP 3000/12 Large Scale CNC Pipe Cutting Machine:

Model Technical Parameter | 5 Axis CNC-CP 3000/12 CNC Pipe Intersection Cutting Machine |

Fitting Diameter Range of Workpiece (mm) | 600 ~ 3000 |

Fitting Max. Length of Workpiece (mm) | 12000 |

Fitting Thickness of Workpiece (mm) | 6~100 mm for flame cutting; 3 ~ 25mm for plasma cutting |

Fitting Cutting Speed | 200∼800mm/min. for flame cutting Around 200~ 2000mm/min. for plasma cutting (Based on thickness of Pipe and Plasma Power) |

Effective CNC Control Axis | 5 Axis of X/Y/Z/A/B X Axis: For cutting torch moving along pipe length direction; Y Axis: For managing CW/CCW pipe rotation; Z Axis: For cutting torch ascend and descend; A Axis: For tilting utting torch along pipe radius; B Axis: For tilting cutting torch along pipe length direction

|