A. The Usage and Specialty of 3 Axis 3000/12 Large Size Plasma Oxy-fuel CNC Pipe Cutting Machine:

1. The 3 Axis 3000/12 Flame and Plasma Large Size CNC Pipe Intersection Cutting Machine is “the simplest and largest” standard model, among all products of CP series Plasma Oxy-fuel CNC Pipe Intersection Cut Machine;

2. Main Specification of 3 Axis Large Size CNC Pipe Cutting Machine:

The overall size of workpiece pipes in this model is same as 5 Axis 3000/12 and 7 Axis 3000/12 Large Size CNC Pipe Cutting Machine:

1) Diameter of pipes is up to Φ3000mm;

2) The longest Length of pipes can be 12m;

3) Wall thickness of pipes can be 100mm for flame cutting, and 25~50mm for plasma cutting;

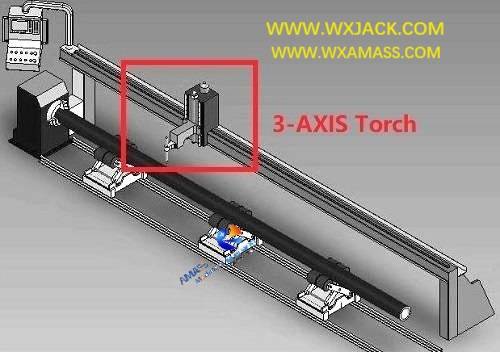

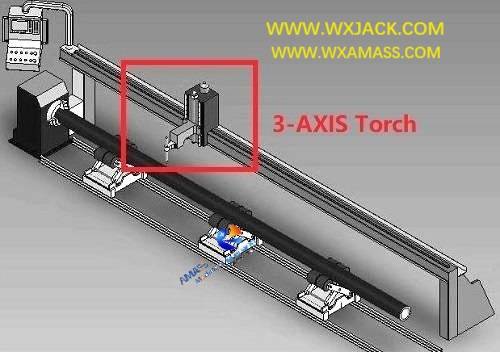

4) Cutting Torch in 3 Axis 3000/12 Large Size Plasma Oxy-fuel CNC Pipe Intersection Cut Machine: (Fig.1)

3. Control Axis of 3 Axis Large Size CNC Pipe Cutting Machine:

Shown in the above sketch, in all the sizes of 3 Axis CNC Pipe Cutting Machine, be it small size/ medium size/ or large size, the cutting torch moves up and down along axial direction of pipes, forward and backward along longitudinal direction of pipes, without swing for making beveling.

B. Characteristics of 3 Axis 3000/12 Large Size CNC Pipe Intersection Cutting Machine:

1. Support of Large Diameter Pipes in Large Size CNC Pipe Intersection Cutting Machine: (Fig.2)

Shown in the attached 6th photo and above photo, in Large Size CNC Pipe Cutting Machine, workpieces are laid on the array of supporting turning rollers;

2. What does “Simple” Mean for 3 Axis 3000/12 Large Size CNC Pipe Intersection Cutting Machine?

1) Here the “Simple” means less control axis compared with 5 Axis and 7 Axis Large Size CNC Pipe Intersection Cut Machine;

2) Removing below control axis from 7 Axis Plasma Oxy-fuel CNC Pipe Cutting Machine:

a) Cutting torch swing along axial and radial direction of the pipe;

b) Cutting torch movement along radial direction of the pipe;

c) As well as adjustment on span of turning rolls supporting the pipe;

3) The 3 axis CNC Pipe Intersection Cutting Machine keeps control on pipe rotation, cutting torch up and down, and its movement along axial direction of the pipe;

4) In this way, the 3 axis CNC Pipe Cutting Machine retains the basic job of pipe cutting off in required length, cutting hole in the pipe with straight edge, as shown in the attached photos;

3. When to Choose 3 Axis, 5 Axis and 7 Axis Plasma Oxy-fuel Large Size CNC Pipe Intersection Cutting Machine?

1) The choice among 3 axis, 5 axis and 7 axis CNC Pipe Cutting Machine usually originated out of the demand on cutting kerf on pipe or not: whether it need to be finished together with the whole pipe cutting or not;

2) 7 axis CNC Pipe Intersection Cutting Machine has basic same function as the 5 axis CNC Pipe Cutting Machine, but with more delicate control on movement of turning rollers;

3) Usually, the pipes cut with the 3 axis CNC Pipe Cutting Machine has thinner thickness. Because thin thickness of pipes are difficult to have beveling, and usually not necessary.

C. Technical Parameters of 3 Axis 3000/12 Large Size Plasma Oxy-fuel CNC Pipe Cutting Machine:

Below is specification of the 3 Axis CNC-CP 3000/12 Large Size CNC Pipe Intersection Cutting Machine:

Model Technical Parameter | 3 Axis CNC-CP 3000/12 Large Size Plasma Oxy-fuel CNC Pipe Intersection Cutting Machine |

Available Diameter Range of Pipe for Cutting (mm) | 600 ~ 3000 |

Max. Length of Pipe for Cutting (mm) | 12000 |

Available Thickness of Pipe for Cutting (mm) | 6~100 mm for Oxy-fuel flame cutting; 3 ~ 25mm for plasma cutting |

Thermal Cutting Speed | 200∼800mm/min. for flame cutting Around 200~ 2000mm/min. for plasma cutting (Based on thickness of Pipe and Plasma Power) |

CNC Control Axis | 3 Axis of X/Y/Z: X: Cutting Torch Move along pipe length; Y: Pipe Rotate; Z: Cutting torch move up and down |