From this section the three consecutive segments we will have a brief introduction on three critical machines in production of large diameter longitudinal submerged arc welding pipe, which is used in the field of oil and gas pipeline.

1. Large Diameter Longitudinal Submerged Arc Welding Pipe Production Line Machine:

The major equipment in this line for producing oil gas pipeline include:

1) Heavy duty Plate Moving type Edge Milling machine;

2) Heavy duty Plate Pre-Bending machine;

3) 2000Ton Press Brake;

4) Heavy duty Pipe Forming machine;

5) Heavy duty Pipe Tack Welding machine;

6) Large Pipe Internal Longitudinal Welding machine;

7) Large Pipe External Longitudinal Welding machine

The three machines marked in blue oblique font will be discussed from this section.

2. Working Principle of Plate Moving type Heavy duty Plate Chamfering Machine:

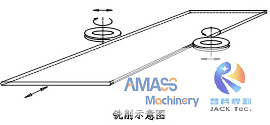

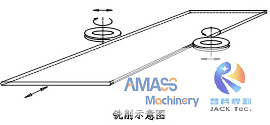

1) As its name implies, compared with traditional plate beveling machine (Please check the corresponding product group “Plate beveling machine” in the same “Products” of this website), the most conspicuous difference lies in its edge milling process. Please check below illustration: (Fig.1)

2) In the process of high speed edge milling, the workpiece plate travels through the gap between the pair of milling heads, got its edge chamfered at the same time;

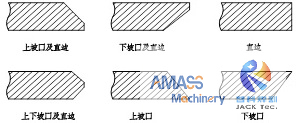

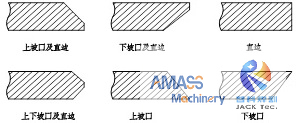

3) The chamfers that can be made with this Edge Milling equipment please check below: (Fig.2)

4) The two sets of edge milling units, which are installed at both sides of machine body, can move transversely along the rail under motor drive, fitting for varied width of plate to be chamfered.

3. Specialty of Plate Moving type Heavy duty Plate Edge Milling Machine:

1) As discussed on its working principle, the first specialty of this plate beveling equipment is its working mode of workpiece traveling and getting chamfered simultaneously;

2) With both sides of high speed chamfering at the same time, the productivity on edge milling operation is also doubled;

3) The milling head is custom-made, of 55kW high power;

4) The velocity of corresponding high speed edge milling process can be as high as 5000mm/min., compared with max. conventional edge milling speed of 1000mm/min.

4. Technical Parameters of Plate Moving type Heavy duty Plate Chamfering Equipment:

Model Technical Parameter | Heavy duty XBJ |

Max. Edge Milling Length (mm) | No restriction |

Power of Milling Head | 55kW x 2 |

Plate thickness | 12∼50mm |

Edge Milling speed | 3000∼5000mm/min. (VFD, Inverter Control) |

Idle speed | 5000mm/min. |