A. Outline on Usage, Main Action, and Advantage of PR24 Automatic Tilting Pipe Rotating Welding Positioner:

1. Usage of PR24 Model Tilting Pipe Welding Rotator:

1) This is a kind of special design Welding Positioner developed by our company on the basis of advanced technique in China and abroad;

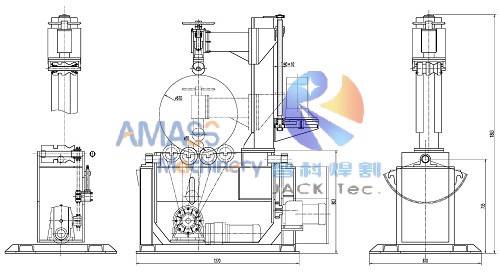

2) This tilting ability Welding Pipe Rotator is used for fabricating on pipe, pipe flange, pipe elbow in automatic way;

3. Action Degrees of Freedom in Tilting Pipe Welding Positioner: (Fig.1)

As indicated in the above photo:

1) Tilt the secured workpieces (Pipe, pipe flange, pipe elbow) forward and backward within certain angular scope;

2) Revolve the secured workpieces under required welding speed by means of rotating a group of welding turning roller on its worktable;

4. Advantages of PR24 Model Tilting Pipe Welding Rotator:

1) Operation of the downward pressing mechanism for holding the workpieces firmly, is the combination of electric motor drive and manual adjustment, making steady and regular revolving speed of workpieces;

2) In this way, superior quality of welding seam can be fully guaranteed, and welder labor intensity is relieved, raising the overall productivity.

B. Structure and Technical Performance of PR24 Model Tilting Pipe Welding Positioner:

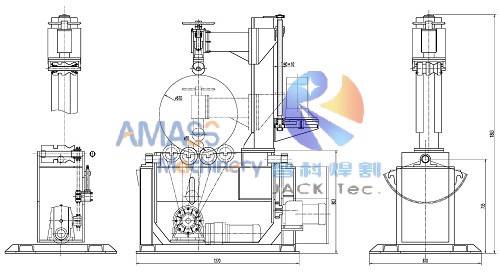

Design sketch of the machine: (Fig.2)

1. Main Units of PR24 Model Pipe Rotating Welding Positioner:

1) Mechanical main frame;

2) Workpiece tilting mechanism;

3) Workpiece revolving mechanism;

4) Downward pressing mechanism;

5) Conductive device;

6) Electric control system;

2. Mechanical Frame of PR24 Model Tilting Welding Pipe Rotator:

1) This unit is for the purpose of holding tilting mechanism, revolving mechanism and downward pressing mechanism;

2) It is welding structure member, which is machined precisely after welding and annealing, with high strength and anti-impact performance;

3. Tilting Mechanism of PR24 Model Pipe Welding Positioner: (Fig.3)

1) This unit is for tilting the clamped workpiece in the range of ±45°;

2) Its driving is adopted with gear reducer with braking function. So, workpiece can be tilted and stopped at any angular position within the scope of ±45°;

3) Extreme angular position of tilting is controlled with limit switches;

4) In PR24 model Pipe Welding Rotator, transmission chain of the tilting mechanism is: Tilting driving motor → Gear reducer → Small gear →Sector gear → Workpiece tilting;

4. Revolving Mechanism of PR24 Model Pipe Rotating Welding Positioner: (Fig.4)

1) Revolving linear velocity of the workpiece on Welding Pipe Rotator is controlled with Chinese TANWAN brand TAIAN A.C. inverter, making the speed controllable continuously and stepless;

2) Transmission chain of the revolving mechanism is: Revolving driving motor → Worm gear reducer → Chain and sprocket →Rollers → Workpiece revolving;

5. Downward Pressing Mechanism in PR24 Model Tilting Welding Pipe Rotator: (Fig.5)

Operation of this unit is realized with 2 stages of action:

1) First, lead leadscrew moves up and down driven with gear reducer;

2) Then, by means of manual turning handwheel and corresponding leadscrew nut, and guided with sliding shaft and bushing;

Making the pressing roller moves up and down, which in turn press tightly different diameter workpieces;

6. Pressing Roller of PR24 Model Pipe Welding Positioner:

1) These turning rollers are made of steel;

2) There are 2 types of turning rollers: V section and U section, which can not only be used for firmly holding pipe rotation, but also pipe flange rotation. So, it has very extensive use;

7. Conductive Device in PR24 Model Pipe Welding Positioner:

1) There is conductive device installed on revolving worktable of the machine, thus forming the conductive circuit for welding operation;

2) The conductive capacity is 1000A.

C. Range of Supply of PR24 Model Tilting Welding Pipe Rotator:

1) Main Body: Including mechanical frame, tilting mechanism, revolving mechanism, downward pressing mechanism;

2) Electric Control System: 1 set;

3) Technical Documents: Quality Certificate, Packing List, Manual Book, Electric Diagram, Foundation Drawing of the Pipe Welding Positioner.

D. Technical Parameters of PR24 Model Pipe Rotating Welding Positioner:

PR24 Tilting Pipe Welding Positioner |

Parameter | Specification | Note |

Applicable Pipe Diameter | Φ100 mm ~Φ610 mm |

|

Roller Linear Speed (Welding Speed) | 120-1000 mm/min. | Inverter control, continuous stepless adjustment |

Elevation Speed of Pressing Roller Downward Stroke | 245 mm/min. | Motor Drive |

Pressing Roller Downward Stroke | 510 mm |

|

Loading Capacity of Welding Pipe Rotator | 1.5 Ton |

|

Overall Dimension (Height x Width x Depth) | 1863 mm x 1270 mm x 870 mm |

Roller Span | 150/420mm | 2 Shifts, adjusted manually |

Tilting Speed | 1.2 rpm |

|

Tilting Angle Range | -45 º∽ +45º |

|

Diameter of Rollers | Φ135 mm |

|

Material of Rollers | 45# Steel, machined with slots | For convenience of fixing flange |

Max. Welding Current | 1000A | Max. Welding Ground Current |

Power Electricity | AC380V,50Hz,3 Phase |

|