Position of CNC Flame Plate Cutting Machine:

1) CNC Flame Plate Cutting Machine (Or, CNC Flame Cutting Machine) is the largest volume product in the family of CNC Strip Plate Cutting Machine;

2) This product section is on the general introduction on the subdivision of the CNC Cutting Machine.

1. Usage of CNC-CG Series CNC Flame Cutting Machine:

1) Function: CNC Flame Cutting Machine is for the purpose of plate shape cutting on metal plate--- Finished products are metal workpieces of various required contour;

Wuxi JACK CNC Flame Plate Cutting Machine in operation: (Fig.1)

2) Applicable Workpieces: This group of CNC Cutting Machine can cut metal plate, majority application is for cutting carbon steel, with thickness from 6mm to up to 200mm (Standard CNC Plate Cutting Machine is for 100~ 150 mm thickness cutting);

3) Unique Capability of CNC Flame Cutting Machine: Although currently there are four types of metal plate cutting technology in the industry: Flame cutting, Plasma cutting, Laser cutting and Water Jet Cutting, the remaining three types are all applicable for thin and medium thickness plate cutting. For thick thickness plate cutting (≧35mm), CNC Flame Cutting Machine has incomparable advantages;

4) Cutting Media of CNC Flame Cutting Machine: One of the requisite cutting gas of this CNC Plate Cutting machine is Oxygen (Cutting oxygen and preheating oxygen); The other is either Acetylene (Majority) or Propane (Minority). In this sense, the CNC Flame Cutting machine can be viewed as adopting Oxyacetylene plate cutting technology;

5) Application Form of CNC Flame Cutting Machine:

a) For this Oxyacetylene CNC Strip Plate Cutting Machine, most of the equipment are combination of CNC Flame Plate Cutting Machine/ Strip Plate Cutting Machine and or Triple Plate Cutting Machine:

b) Equipped with strip torch and or triple torch, the CNC Plate Cutting Machine has the capability of plate shape cutting straight and slit cutting in X/Y axis within horizontal plane, as well as edge beveling (Just like Edge Milling Machine), making it a versatile CNC Cutting Machine;

6) Extensive Use of CNC Flame Plate Cutting Machine: Like other CNC Strip Plate Cutting Machine, the CNC Flame Cutting Machine can be used as an individual equipment in any of the facilities in production industry;

7) CNC-CG4000 CNC Strip Plate Cutting Machine: Besides, the 4,000 mm (Refers to gantry span) CNC Strip Plate Cutting Machine is the basic and also the first equipment in terms of process flow and layout of H Beam Production Line and BOX Beam Production Line.

2. Structure of CNC Flame Cutting Machine:

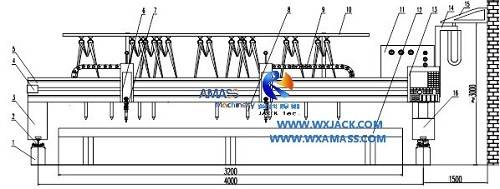

Structure of a typical set of CNC Flame Plate Cutting Machine please check below sketch:

(Fig.2)

1) Longitudinal Rail;

2) Longitudinal Traveling Unit;

3) Steel Band Transmission Unit;

4) Mechanical Main Frame of the CNC Strip Plate Cutting Machine;

5) Transverse Traveling Unit;

6) CNC Flame Cutting Torch (Standard configuration is two sets in CNC Strip Plate Cutting Machine);

7) Strip Cutting Torch (Standard configuration is nine sets in CNC Strip Plate Cutting Machine);

8) Transverse Cable Drag chain;

9) Gas Tube Hanging Rack;

10) Cutting Gas Panel of the CNC Flame Cutting Machine;

11) Cutting Platform (Made by Customer);

12) CNC Board operating station of the CNC Plate Cutting Machine;

13) Longitudinal Cable Rack;

14) Bracket of Longitudinal Cable Rack (Made by Customer) of CNC Strip Plate Cutting Machine;

15) Cutting platform gantry beam support (Customer prepare)

We will have thorough introduction on each of these units applied in CNC Flame Cutting machine in the follow product sections.

3. Classification of CNC Flame Cutting Machine Based on Gantry Size:

1) "Standard" Model: The standard size of CNC Strip Plate Cutting Machine has gantry span of 4,000 mm (Which means, center distance of the two pieces of longitudinal guiding rails is 4,000 mm), which can meet the demand of the largest group of customers;

2) "Tailor Made" Models: On that basis, the CNC Flame Plate Cutting Machine also has gantry span of 3,000 mm/ 5,000 mm and wider. The biggest currently is 15,000 mm;

3) Topics Covered: We will go on to have introduction on standard and tailor made models/ main units of the CNC Flame Plate Cutting Machine/ Strip Plate Cutting Machine and Triple Plate Cutting Machine in the following up product sections.

4. Technical Parameters of the CNC Strip Plate Cutting Machine:

For each of the model of the CNC Flame Cutting machine we will list it in the corresponding product section.