A. Specialty and Application of XBJ-5 General Purpose Plate Edge Milling Machine:

1. What is Special with XBJ-5 Steel Plate Edge Beveling Machine:

1) The XBJ-5 single head model equipment is a kind of “Special made” product of XBJ and SXBJ series machine;

2) Here, the implication of “Special” lies in the max. edge milling stroke of the XBJ-5 model: 5000mm;

3) Because currently in the application field of XBJ and SXBJ models General Purpose Plate Beveling Machine, the standard or popular specifications on max. effective edge milling stroke in machine models for edge milling: 3,000mm, 4,000mm, 6,000mm, 9,000mm, 12,000mm, 15,000mm, 18,000mm. Correspondingly, the common seen models of these machines are: XBJ/ SXBJ-3/ 4/ 6/ 9/ 12/ 15/ 18 respectively;

2. The Importance of XBJ-5 General Purpose Plate Beveling Machine:

1) The most majority applicating cases of XBJ and SXBJ series metal plate machines for plate edge milling fall within this group, which accounts for over 90% practical consumption volume of the equipment;

2) On the other hand, there are definitely some application scenarios, when “special” length of edge milling on sheet metal plate do stand an important position, and this is the proper applicable cases when the “special made” models of the machine are designed and produced for customers, such as this XBJ-5 model.

B. Technical Specialties of XBJ-5 Single Head General Purpose Plate Edge Beveling Machine:

1. Main Functions of XBJ-5 General Purpose Plate End Milling Equipment:

1) With the “non-standard” length of its max. valid plate chamfering and beveling stroke, the structure, chamfering process, and outsourced parts of this XBJ-5 model equipment are all the same as that of standard models machine;

2) The major difference between special model and standard model Edge Milling Machine is, during development and manufacturing process of “special models” , more attention should be given to it including calculation/ design/ control plan of the equipment, and hence more inspection and validation segments in the entire Order to Delivery value chain of the machines;

3) Equipped with the 7.5kW power milling head with adjustable tilting angle, this custom made XBJ-5 Steel Plate Edge Milling Machine has capability of making bevel in the form of various welding grooves on top and bottom edges of the metal plate;

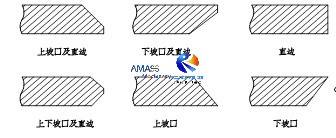

4) Below is sketch list on common seen chamfers available with the Steel Plate End Milling Equipment: (Fig.1)

5) It is a kind of sophisticated and efficient machine, for the purpose of fulfilling preparation on the following on metal plate welding process, and is widely applied in industries of Pressure Vessel, Shipbuilding, Port Machinery, Power Plant, Chemical, Steel Structure, etc.;

6) The finished welding groove on edge of workpiece steel plate machined from Wuxi JACK General Purpose Plate Edge Milling Machine: (Fig.2)

2. Technical Details of XBJ-5 General Purpose Plate Edge Milling Equipment:

1) During edge milling operation on metal plate edge, metal plate is fixed on the machine worktable, by means of a row of hydraulic drive jacks which are installed facing downward;

2) In XBJ models Edge Milling Machine, the installation interval between any two pieces of hydraulic drive jacks is 600mm;

3) For this reason, depending on the valid size of the machine worktable length, which is the nominal working stroke, quantity of these hydraulic drive jacks varies from 5 pieces for XBJ-3 compact size model, to 30 pieces in total for SXBJ-18 large model;

4) The array of hydraulic jacks which press steel plate firmly in the XBJ Steel Plate Edge Beveling Machine: (Fig.3)

5) Another function of XBJ and SXBJ series machine models for steel plate edge milling is, with installation of special arc facer, arc shape welding groove can be machined on edge of workpiece metal plate;

6) The arc shape welding groove produced from Wuxi JACK Metal Plate Beveling Machine: (Fig.4)

C. Technical Parameters of XBJ-5 General Purpose Plate Edge Milling Machine:

Model Technical Parameter | XBJ-5 Single Head General Purpose Plate Edge Beveling Machine |

Max. Plate Edge Milling Length | 5000 mm |

Power and rpm of Milling Head | 7.5 kW, 1440 rpm |

Grooving Angle Range of Milling Head | 0°~ 80° |

Quantity of Hydraulic Drive Jacks | 9 Pieces |

Spindle rpm of Edge Milling Head | 75 ~ 420 r/min., 6 grades by handwheel |

Hydraulic Motor Power | 5.5 kW |

Milling Head Quantity | 1 set |

Plate thickness for Sheet Metal chamfering | 6∼50 mm |

Edge Milling Speed | 130∼1000 mm/min. (VFD, Inverter Control) |

Idle High Speed of Milling Head Moving Carriage | 4000 mm/min. |

Applicable Diameter of Facer Plate | D=Ø125 ~ Ø320mm (Ø200mm For delivery) |

Hydraulic Rated Pressure | 5.5 MPa |

Hydraulic Working Pressure | 3.5 MPa |

Hydraulic System Flowrate | 47 L/min. |

Worktable Width | 450 mm |

Worktable Height | 1050 mm |