1. The Range of HLK Series Bolt Adjustable Welding Rotator:

1) This product section of HLK series Bolt Adjustable Welding Rotator covers the conventional and standard of its type, across the common seen models and specifications;

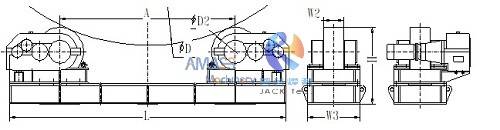

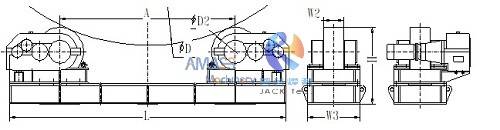

2) Design structure of these Bolt Adjustable Welding Turning Roller please check below sketch. The corresponding parameters please check parameter table at the end of this product section:

Design sketch of Wuxi JACK HLK series bolt adjustable: (Fig.1)

2. How to Select on HLK Series Standard Bolt Adjustable Welding Roller Bed:

From the above information we can see, outline of the welding equipment:

1) Loading Capacity of HLK Standard Welding Rotator:

a) The standard loading tonnage is within the scope of 2 Ton to 1000 Ton, which is very extensive for selection;

b) Tailor made tonnage is available. For example, 2000 Ton;

a) For loading tonnage between 2 Ton to 20 Ton, it is light duty group;

b) For loading tonnage between 40 Ton to 100 Ton, it is medium duty sections;

c) For loading tonnage between 160 Ton and above, it is heavy duty line;

3) Universal Use of HLK Series Standard Welding Roller Bed:

a) As introduced in the former product section of “HLK High Quality Professional Adjustable”, these general purpose Welding Turning Roller can be used for fabrication, rubber lining, polishing, testing, etc.

b) In all, all the jobs that involve rotation of workpieces with barrel contour can be processed in this Bolt Adjustable Welding Rotator.

3. Technical View on HLK series Standard Bolt Adjustable Welding Turning Roller:

1) Welding Turning Roller Ingredient:

a) Light duty and medium duty Welding Rotator can be either PU and metallic combined, or fully metallic:

Rubber / PU turning rollers combine with metallic for light to medium duty models: (Fig.2)

Fully metallic turning rollers for heavy duty models: (Fig.3)

b) Heavy duty Welding Rotator can only be equipped with fully metallic turning rollers;

2) Prime Mover in HLK Series Standard Welding Rotator:

These multi functional Welding Turning Roller are basically motor drive:

a) A.C. worm gear is used in the HLK series light duty models;

b) A.C. gear reducer is used in the HLK series medium duty and heavy duty Welding Roller Bed;

c) In early developing phase, D.C. motor is used for driving the Welding Turning Roller, so as to acquire ideal welding speed changing management. The downside of D.C. motor is high purchase cost/ complicated wiring and maintenance/ Large size and heavy weight;

d) The only exception is HLK series Anti Drifting Welding Roller Bed, which adopts hydraulic uplift for its turning rollers and workpiece lift;

e) So, this series of HLK model Standard Welding Turning Roller is electric motor drive for welding operation.

4. Mechanical Characteristic of HLK Series Standard Bolt Adjustable Welding Rotator:

1) Pedestal in Operation of Welding Roller Bed:

a) Pedestal of the driving and idler section Welding Turning Roller are all box type structure, with large capacity and long using time: (Fig.4)

b) There are hoisting holes on the pedestal of these HLK series Bolt Adjustable Welding Roller Bed. Mounting holes on the pedestal are machined finely post welding, ensuring mounting precision;

2) Welding Roller Bed:

Driving and idler section of Welding Roller Bed are strengthened with ribs and stiffeners, for the purpose of capability on taking on heavy duty jobs at customer site, guaranteeing on stable and long service life of the equipment;

3) Gear type Reducer of HLK Series Welding Turning Roller:

The gear type reducer used in medium duty and heavy duty Bolt Adjustable Welding Rotator features in reasonable structure, smooth running, little bulk, great torque and low noise;

4) We will explore on the HLK series Bolt Adjustable Welding Turning Roller in further detail, on its categorical products in the subsequent following sections.

5. Technical Parameters of HLK Series Standard Bolt Adjustable Welding Roller Bed:

HLK Series Standard Bolt Adjustable Welding Turning Roller |

Model | HLK2 | HLK5 | HLK10 | HLK20 | HLK40 | HLK60 | HLK80 | HLK100 | HLK160 | HLK250 | HLK400 | HLK500 | HLK630 | HLK800 | HLK1000 |

Max. loading (Ton) | 2 | 5 | 10 | 20 | 40 | 60 | 80 | 100 | 160 | 250 | 400 | 500 | 630 | 800 | 1000 |

Work-piece | D (mm) | ø250 ~1800 | ø250 ~2300 | ø320 ~2800 | ø500 ~3000 | ø600 ~4200 | ø700 ~5000 | ø700 ~5500 | ø700 ~6000 | ø1000 ~6000 | ø1000 ~7500 | ø1000 ~7500 | ø1000 ~8000 | ø1000 ~8500 | ø1500 ~9000 | ø1500 ~10000 |

PU roller (mm) | D1 | 200 | 250 | 300 | 350 | 400 | 450 | 500 | 550 | Metallic rollers are used for large tonnage roller bed |

W1 | 80 | 100 | 120 | 120 | 120 | 120 | 120 | 120 |

Metallic roller (mm) | D2 | 190 | 240 | 290 | 340 | 394 | 444 | 490 | 538 | 620 | 700 | 800 | 800 | 850 | 1000 | 1000 |

W2 | 16 | 20 | 38 | 45 | 60 | 70 | 70 | 100 | 220 | 260 | 300 | 300 | 350 | 350 | 350 |

Linear speed (m/h) | 6-60 (Speed control VFD) |

Motor power (kW) | 2×0.18 | 2×0.37 | 2×0.55 | 2×1.1 | 2×1.5 | 2×1.5 | 2×2.2 | 2×2.2 | 2×4 | 2×5.5 | 2×5.5 | 2×5.5 | 2×7.5 | 2×7.5 | 2×11 |

Above are the standard parameters of the HLK Adjustable Welding Rotator by Bolt, also we can design on customer requirement. |