Working Site of Wuxi JACK CNC-DX1540 CNC H Beam End Face Milling Machine:

1) Attached the first photo is a group of Steel Structure Milling and Facing Center exported to Belarus by Wuxi JACK;

2) Same as Automatic SAW Welding Center, this facing center is composed of 2 sets of CNC-DX1540 Steel Structure CNC End Face Milling Machine and supporting systems, to meet sophisticated demand from customer.

1. Purpose of the Steel Structure Milling and Facing Center:

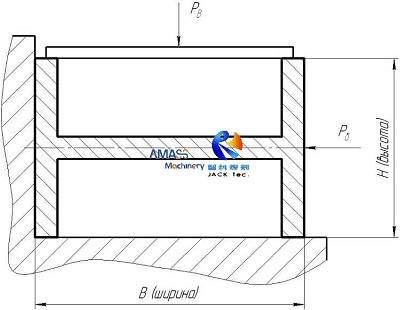

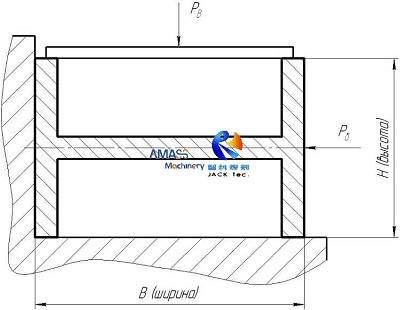

1) Sketch of the workpiece (H Beam) to be processed in the CNC-DX1540 CNC H Beam End Face Milling Machine in this Steel Structure Milling and Facing Center is as below: (Fig.1)

2) This Steel Structure Milling and Facing Center is used for H Beam ends milling (including cone H Beams with tilt angle of one flange up to 15°);

3) One set of the CNC-DX1540 CNC H Beam End Face Milling Machine can make the linear movement, and the other set of the CNC machine can be turned around 0~60°;

3) Workpiece Specifications for Welding Structure CNC End Face Milling Machine of Steel Structure Milling and Facing Center:

a) Rolled and welded H Beam (I Beam), welded BOX Beam, length ranging in 6~ 24m;

b) Cross section size has scope of 250x250mm ~ 1500x 4000mm;

c) Cone angle of the workpiece (H Beam) flanges has degree range of 0~15°;

d) End face of the workpiece (H Beam) has inclination angle of 0~60°;

e) Guaranteed flatness of processed surface with the End Face Milling Machine is 0.22mm/m2;

f) Roughness of processed surface is Ra 12.5 after end face milling.

2. Formation of the Steel Structure Milling and Facing Center:

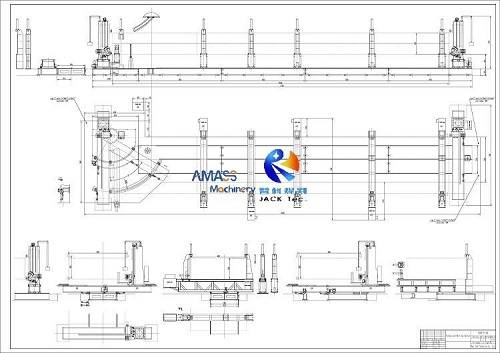

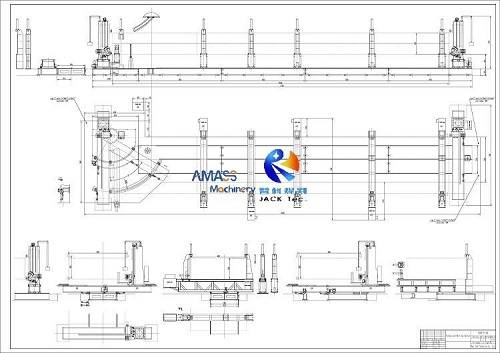

1) General design drawing of Steel Structure Milling and Facing Center: (Fig.2)

It occupies total workshop land area of: 29m length by 8m width, in the height of 4.5m, including 2 sets of CNC-DX1540 CNC H Beam End Face Milling Machine at both ends:

2) This Steel Structure Milling and Facing Center is composed of:

a) Two sets of CNC-DX1540 Steel Structure End Face Milling Machine, of which one set is movable under motor drive along the 24m rail, the other set is stationary, but has capability of 0~60° revolving for the convenience of inclined end face milling;

b) Five sets of hydraulic drive workpiece fixation tables, for holding the workpiece processed with these two sets of CNC-DX1540 Steel Structure CNC End Face Milling Machine;

c) Turning table of 0~60° range under motor drive, which is installed beneath the stationary CNC machine;

d) 24m long double rails/ Control system/ Hydraulic system of the Steel Structure Milling and Facing Center.

3. Technical Brief on the Steel Structure Milling and Facing Center:

1) Type of Processing Equipment: CNC-DX1540 Welding Structure CNC End Face Milling Machine. Its motion and movement are managed with CNC and servo motors; Operation is realized with touch screen on the CNC;

2) Main Technological Operations Adopted: End face milling by means of high power (7.5kW) milling head, with its angle and rotating speed adjustable;

3) Operation: During work, two sets of the Steel Structure CNC End Face Milling Machine have facing operation at the both faces of the workpiece at the same time. To cater for variable workpiece specification (Length and side face tilting angle), one set of the CNC machine moves along the rail, the other machine can be revolving within 0 ~ 60°;

2) The Two Sets of CNC-DX1540 CNC H Beam End Face Milling Machine:

a) Before processing, the CNC machines are reliable fixed with the hydraulic clamping devices;

b) Angle positioning adjustment of the turning machine, relative to the workpiece (H Beam) is 0~ 60˚ with accuracy of 2' (minutes). For the stationary tilting CNC machines, a circular ruler is used for rotation angle measurement and control;

3) Milling head is the core unit in the two sets of CNC machines; (Please see the attached 4th photo);

The General Technical Specialty of the CNC H Beam End Face Milling Machine:

a) Milling heads quantity in each set of the CNC H Beam End Face Milling Machine is 1 piece, available for horizontal and vertical machining, with model of MU-9S (Professional producer);

b) Milling cutter turning speed range is 65~ 715 rpm (There are 9 positions of turning speed to be changed, with manual adjustment);

c) Material of the milling blade is mark and type of used carbide blade SPCN1504ED;

d) Milling head boom size is 0~200 mm, and rotation angle is 0~ 45°;

e) During work of the CNC H Beam End Face Milling Machine, adjustment of milling heads boom is performed by manual mechanical drive; And adjustment of milling heads rotation angle in the vertical plane is performed by manual mechanical drive.

4) The 5th and 6th photos record on site working condition of the Steel Structure Milling and Facing Center at customer site.