A. Usage of DX0815 Steel Structure Flange Milling Machine:

1. Nature and Task: This is a set of special design and produced DX series H Beam End Face Milling Machine, referring to both milling stroke and workpiece fixture;

2) Workpiece: The machine will mainly work on customer designated special working parts flange, involving structure/ size/ style;

2. Function and Special Point of the DX0815 Metal Structure End Face Milling Machine:

1) Expected Workpieces: This machine is specifically designed for implementing surface milling on a kind of steel structure end flange working parts in the form of flat “body”:

2) Special Requirement on Workpieces Secure into the End Face Milling Machine:

a) Here customer asks for fixture to clamp on the upright orientated end plate flange directly;

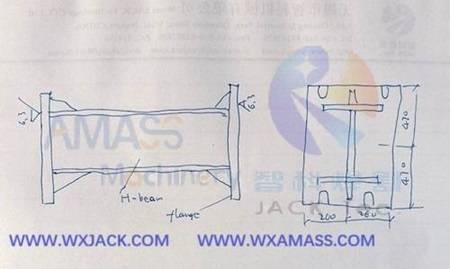

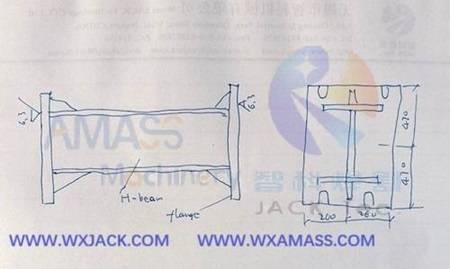

b) After getting surface milled in the DX0815 Flange Milling Machine, the end plate flange will be welded onto both ends of the H Beam still in vertical orientation, as indicated in below hand made sketch:

c) Side view on end plate flange working parts to be processed: (Fig.1)

3. Comparatively, for conventional workpieces of long length body H/ I/ Cross/ BOX Beams/ Pipe, which, by means of its long body, is relatively easy to be clamped into the End Face Milling Machine for carrying out end face milling operation. Shown as below:

2) Clamping long length H Beam into Wuxi JACK “Conventional” CNC H Beam End Face Milling Machine: (Fig.2)

4. Workpiece of DX0815 Steel Structure End Face Milling Machine:

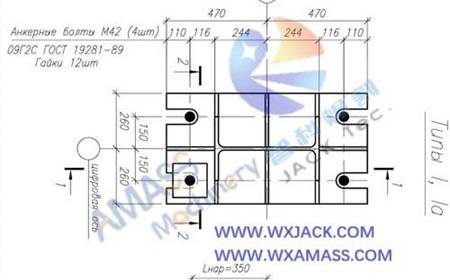

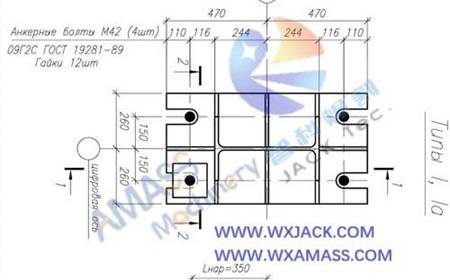

1) Explained as above, working parts is a piece of flat flange end plate, with thickness 70mm. Its single side machined surface has special design contour and hole:

2) From customer: Expected single side machined surface of working parts planned for DX0815: (Fig.3)

B. Technical Index of DX0815 Metal Structure Flange Milling Machine:

1. 3 Degree of Freedom for Operating DX0815 End Face Milling Machine:

In this special size End Face Milling Machine, the 7.5kW milling head can move in adjustable working speed, and perform surface milling along 2 directions:

1) X axis along horizontal way;

2) Y axis along vertical way;

3) Besides, the milling head can tilt 0° ~ 45°, to fulfil slant surface milling of workpiece: (Fig.4)

2. Max. Effective Working Stroke and Velocity in DX0815 Flange Milling Machine:

1) Horizontal X axis: Max. 1500mm;

2) Vertical Y axis: Max. 800mm;

3) Adjustable Working Velocity: Both axis working speed is controlled with A.C. inverter and manipulated with potentiometer, available in the scope of 100~800 mm/min.;

3. Finished Machining Precision Promised on DX0815 End Face Milling Machine:

1) Finished Milling Linearity: 0.12mm/ 1,000mm; Or, 0.18mm/ 1,500mm;

2) Finished Surface Flatness: 0.13mm/ m2

C. Structure and Main Units of DX0815 H Beam End Face Milling Machine:

1. Structure and Working Principle of the Special Design Flange Milling Machine:

This special design equipment has the similar structure and working manner as conventional H Beam End Face Milling Machine:

1) Its execution unit the 7.5kW milling head is installed onto motorized drive upright column;

2) During Work:

a) Y Axis Movement: Under motor drive and controlled with VFD, the milling head moves up and down along the heavy duty precise linear guiderail on the upright column, fulfilling Y axis vertical direction end face milling operation;

b) X Axis Movement: The upright column moves along horizontal base bed, also under motor drive and controlled with VFD, fulfilling X axis horizontal direction end face milling operation;

3) Workpiece Secure: The special design workpiece fixture clamping table is put alongside lefthand of the mechanical main body of the Flange Milling Machine:

4) Overall appearance of the unpainted DX0815 Metal Structure Flange Milling Machine for testing at Wuxi JACK facility: (Fig.5)

2. Main Units of DX0815 Steel Structure Flange Milling Machine:

1) Upright Vertical Column, Including: Milling head/ Vertical slides/ Column body/ Elevating transmission mechanism/ Guard cover;

2) Horizontal Slides, Including: Work table/ Machine body/ Feeding transmission system/ Guard cover;

3) Hydraulic Clamp Working Table, two pcs, hydraulic station;

4) Electric Control System, Including: Control board/ Operating pedant/ A.C. inverter

5) Tool for Fitting Facing Blade, Including: 200 standard facing blade bed/ Fitting tool, etc.

D. Operation on DX0815 Steel Structure Beam End Face Milling Machine:

1. Operating Zone of End Face Milling Machine:

1) During work, operator stands between mechanical main body of the machine and special design hydraulic drive workpiece clamping table, and manages on operation by means of overhang pendant:

2) The Russian language 360° turning hanging pendant of the DX0815: (Fig.6)

2. Workpiece Fitting On into the DX0815 Metal Structure Beam End Face Milling Machine:

This is the topic focus during business negotiation on the machine:

1) Before official running, the workpiece flange is put upright orientation, held firmly into the fixture, and face to face toward facing cutter of milling head:

2) Workpiece flange fixture and end face milling, in the DX0815: (Fig.7)

E. Technical Parameters of DX0815 Steel Structure Flange Milling Machine:

№ | Parameter | Value | Note |

DX0815 Metal Structure Flange Milling Machine |

1 | Max. Cross Section of Workpiece H × W | 800×1500 mm | Vertical stroke is 800mm; Horizontal stroke is 1500 mm |

2 | Horizontal Facing Speed | 100~800 mm/min. | A.C. Inverter Control |

3 | Horizontal Slides Idle Speed | 1200 mm/min. |

|

4 | Milling Head Vertical Facing Speed | 100~800 mm/min. | A.C. Inverter Control |

5 | Finished Milling Linearity | 0.12 mm/m; 0.18mm/ 1.5m; |

6 | Finished Surface Flatness | 0.13 mm/ m2 |

|

7 | Horizontal Feeding Motor Power | 1.5 kW |

|

8 | Vertical Feeding Motor Power | 2.2 kW |

|

9 | Milling Head Motor Power | 7.5 kW |

|

10 | Spindle rpm of Facing Head | 75 ~ 420 rpm. | 6 sections, adjusted by hand wheel |

11 | Tilt Angle Range of Facing Head | 45° | adjust by manual |

12 | Diameter of Facing Blade Bed | φ 125 ~ 320 mm |

|

13 | Travel Stroke of Milling Head Spindle | L=100 mm |

|

14 | Hydraulic Clamp Working Table | One set 2 pcs |

|

15 | Hydraulic Station Power | 3.0 kW |

|

16 | Worker Stand Working Table | One set |

|

17 | Horizontal Move Cable Input | Drag chain |

|

18 | Railway of H Beam End Face Milling Machine | Heavy duty precise linear guideway | Taiwan made HIWIN |

19 | Milling Tool which Factory configuration | GMA200 | Diameter is 200mm |

20 | Power Specification | 380V, 50Hz, 3P |

|