A. The Overview on Characteristic and Usage of 5 Axis 1400/6 High Efficiency Oxy-fuel and Plasma CNC Pipe Intersection Cutting Machine:

1. Overall Dimension of the 5 Axis 1400/6 CNC Pipe Cutting Machine:

As can be seen from the attached photo, this model 5 Axis 1400/6 has the shortest length in product group of CP series Oxy-fuel and Plasma CNC Pipe Cutting Machine. For small to medium diameter of Φ1400mm grade, this length has wide application;

2. Function of the 5 Axis 1400/6 CNC Pipe Intersect Cutting Equipment:

1) The 5 Axis control (X/Y/Z/A/B) makes this High Efficiency CNC Pipe Intersect Cutting Equipment fulfilling the tasks of straight edge cutting and slant edge beveling within one time operation:

2) The cut off working parts from Wuxi JACK 5 Axis 1400/6 High Efficiency CNC Pipe Cutting Machine: (Fig.1)

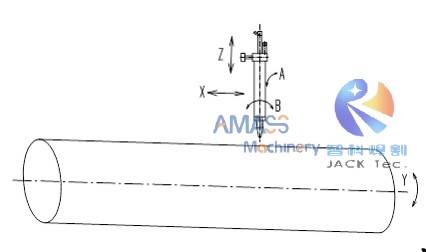

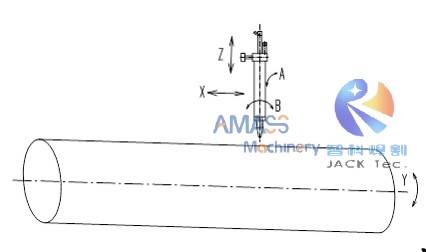

3) The 5 Axis Indication in Wuxi JACK 5 Axis High Efficiency CNC Pipe Intersect Cutting Equipment: (Fig.2)

3. Cutting Method in Φ1400mm Grade CNC Pipe Intersection Cutting Machine:

1) As discussed in product section of 6 Axis 1400/6 High Efficiency CNC Pipe Intersection Cutting Machine, plasma cutting, which focus on slag free cutting on small to medium thickness pipes, is more applicable for the specification grade of Φ1400mm, than large scale CNC Pipe Cutting Machine (Φ2000mm ~ Φ3000mm);

2) Besides, oxy-fuel flame cutting is also widely used in this range of CNC Pipe Intersect Cutting Equipment;

4. Workpiece Support and Revolving in Φ1400mm Grade CNC Pipe Intersect Cutting Equipment:

1) This is utilized with friction roller group, which holds and revolves pipe during cutting and beveling step in CNC Pipe Cutting Machine: (Fig.3)

2) In all, the 5 Axis Automatic Flame and Plasma CNC Pipe Cutting Machine is a practical solution for customers, who need to have cutting kerf and slant bevel on pipe edge and body, for the convenience of subsequent welding and assembly. This model of 5 Axis can be renewed to more sophisticated level CNC Pipe Cutting Machine (6 Axis for Φ1400mm diameter, and 7 Axis for Φ2000mm diameter and above) with great ease.

B. Compare on Control System Hardware and Software for 5 Axis and 7 Axis High Efficiency Oxy-fuel and Plasma CNC Pipe Cutting Machine:

1. Industrial computer (CNC) CPU of CNC Pipe Intersection Cutting Machine has modular structure, easy and convenient for expansion and update when necessary;

2. CPU of 5 Axis CNC Pipe Intersect Cutting Equipment is similar to that of the 7 Axis. The difference is: The CPU in 5 Axis CNC Pipe Cutting Machine utilizes 2 less motion control cards than that of the 7 Axis model, which are used for controlling V Axis and W Axis (Cutting torch and friction rollers transverse movement) for running of the 7 Axis CNC Pipe Intersection Cutting Machine;

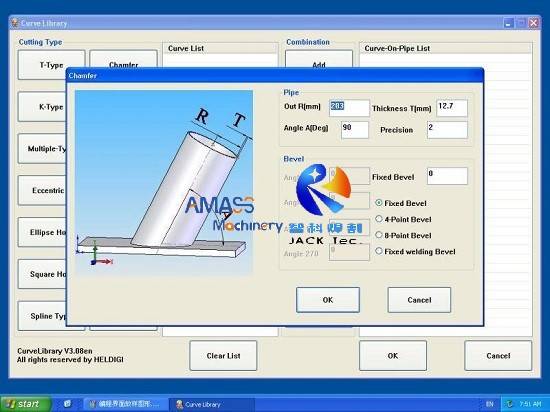

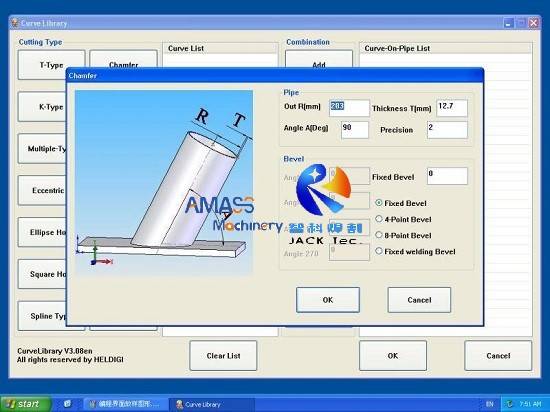

3. Software Operating System is also the similar between 5 Axis and 7 Axis CNC Pipe Intersection Cutting Machine, and so is workpiece library embedded within the CNC. There exists slight variation in HMI (Human Machine Interface) of the software between 5 Axis and 7 Axis CNC Pipe Cutting Machine, but same in hardware;

The HMI of 5 Axis Oxy-fuel and Plasma CNC Pipe Intersection Cutting Machine: (Fig.4)

4. In general, the background program in CP series CNC Pipe Cutting Machine is compiled with structured language, which is available for future program upgrade without much effort, as well as possible 5 Axis expansion into 7 Axis.

C. Technical Parameters of 5 Axis 1400/6 High Efficiency Oxy-fuel and Plasma CNC Pipe Cutting Machine:

Below is specification of 5 Axis 1400/6 Flame and Plasma CNC Pipe Intersect Cutting Equipment:

Model Technical Parameter | 5 Axis CNC-CP 1400/6 High Efficiency Oxy-fuel and Plasma CNC Pipe Intersection Cutting Machine |

Applicable Workpiece Diameter Range | 300 ~ 1400 (mm) |

Applicable Max. Length of Workpiece | 6000 (mm) |

Applicable Workpiece Thickness Range | 6~100 mm for flame cutting; 3 ~ 25mm for plasma cutting |

Applicable Thermal Gas Cutting Speed | 200∼800mm/min. for flame cutting Around 200~ 2000mm/min. for plasma cutting (Based on thickness of Pipe and Plasma Power) |

CNC Control Axis | 5 Axis of X/Y/Z/A/B X Axis: For cutting torch movement along pipe longitudinal direction; Y Axis: For controlling pipe CW/CCW rotation; Z Axis: For managing cutting torch elevation; A Axis: For tilting cutting torch along pipe radius; B Axis: For tilting cutting torch along pipe longitudinal direction |