Assembly Site of Wuxi JACK 3 in 1 I H Beam Assembly Weld Straighten Integral Machine:

1) Attached is a set of High Precision PHJ18 model 3 in 1 Welding H Beam Fabrication Machine taken at Wuxi JACK exhibition area;

2) This photo, due to its panoramic display of the machine, has been pilferage by some competitors and paste this photo onto their website;

3) Actually, Wuxi JACK has ownership of intellectual property on this photo for this Automatic Vertical H Beam Welder. We welcome customers pay a visit to our company to check on site.

A. Delivery and Counterpart Traditional Versus PHJ18 Model Automatic H Beam Production Machine:

1. In terms of its usage, the PHJ series machine can be viewed as a kind of Automatic H Beam Production Machine integrated with 3 core functions: Assembly, welding, and flange straightening;

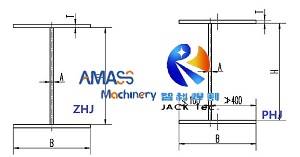

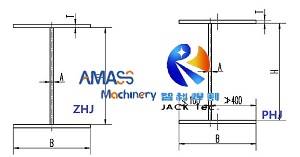

2. This involves not only for welded H Beam/ I Beam production, but also T Beam; Not only symmetric cross section, but also asymmetric. Please check below sketch:

3. Symmetric and asymmetric cross section of finished welded H Beam from 3 in 1 I H Beam Assembly Weld Straighten Integral Machine: (Fig.1)

4. Technical and Application Features of PHJ18 Model 3 in 1 H Beam Fabrication Machine:

1) PHJ18 is medium to large size of PHJ series 3 in 1 I H Beam machine;

2) The max. height of finished workpiece (welded H Beam web) is 1,800mm, belonging to light and medium structure members;

3) Output: PHJ18 model machine produces welded T/ I / H Beam with single pass of workpiece with SAW (Submerged arc welding);

4) The delivered welding toe size on fabricated H Beam is 8~12 mm;

5) Application Range: With this specification range of workpieces, the PHJ18 model machine overlaps with those delivered from heavy duty H Beam Production Equipment, the counterpart model is three sets of machines:

a) Z18 model H Beam Assembling and Tack Welding Machine;

b) LHA5Z model H Beam SAW Welding Machine;

c) HYJ-800 model H Beam Straightening Machine;

5. In this sense, PHJ18 model machine is a very cost effective equipment for customers of steel structure industry. The workpieces that PHJ18 can not cover are those entail welding pass of more than one time. Under such condition, LHA5Z model (H Beam SAW Machine) is a must.

B. High Standard of PHJ Series SAW Automatic 3 in 1 I H Beam Welding Machine:

1. Outline: PHJ series machine is an exquisite design and workmanship equipment, with high standard of implementation in every step of the Order to Delivery process. Here we give several examples as below from assembling to welding to straightening:

2. Assembling Feature in Wuxi JACK 3 in 1 I H Beam Assembly Weld Straighten Integral Machine:

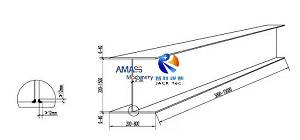

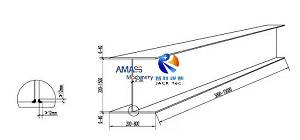

1) Please check the attached 2nd photo. In PHJ series (And ZHJ series) machine, flange and web alignment are realized with several pairs of horizontally installed flat alignment rollers. (3 pairs for flange fitting up, and 2 pairs for web fitting up);

2) These fitting up purpose alignment rollers of this 3 in 1 Vertical H Beam Welder machine have precision machining after forging, and of eccentric type--- Which have additional 1~ 1.5mm inching adjustment stroke for fine tuning of flange and web position;

3. The Other Assembling Feature in Wuxi JACK 3 in 1 I H Beam Assembly Weld Straighten Integral Machine:

1) Please check the attached 3rd photo. There are photoelectric limit switches fit with the machine, for flange and web fitting up respectively;

2) These photoelectric limit switches will emit red light in the process of the machine operation;

4. The attached 3rd Assembling Feature in Wuxi JACK 3 in 1 I H Beam Assembly Weld Straighten Integral Machine:

1) Also in the attached 3rd photo. There is a small hydraulic gadget right behind assembling roller, which has two functions: Its lateral side serves as hard stop for alignment of terminals of flange and web;

2) And, when the workpiece being loaded into the machine has long length and small thickness (Which lacks sufficient rigidity);

3) This gadget will rise up for holding the workpiece, preventing it from swing --- In this way, the best precision of assembling process can be made in the machine;

5. Welding Technical Feature of Wuxi JACK 3 in 1 H Beam Fabrication Machine:

1) The attached 4th photo shows welding torch used in the 3 in 1 machine;

2) It has 2 steps of positioning mechanism: The first is its 45° sliding bracket guided with precise linear guiderail (D.C. motor drive);

3) The second is the manual cross slides for adjustment in horizontal and vertical direction, also guided with precise linear guiderail in the machine;

4) In this way, welding torch can aim at welding seam all the while, to get the best and consistent welding quality in the PHJ series machine all the while;

6. Straightening Technical Feature in Wuxi JACK 3 in 1 H Beam Fabrication Machine:

1) The attached 5th photo was taken at straightening side of the machine;

2) As can be seen from it, to precise manage the straightening process, 2 pieces of rulers are installed at the two downward straightening rollers, to manipulate its downward straightening stroke precisely, making full proof straightening effect of the machine;

7. Main Pressing Roller in Wuxi JACK 3 in 1 Automatic H Beam Production Machine:

1) The attached 6th photo shows upper section of the 3 in 1 machine, that the hydraulic cylinder and Y shape downward bracket for driving the main pressing roller are guided with 4 pieces of precise linear guiderails at the internal surface of gantry beam;

2) In this way, the stable and precise running can be got with the PHJ series machine:

3) Finished welded H Beam sketch to be produced from 3 in 1 machine: (Fig.2)

C. Technical Parameters of PHJ18 Model 3 in 1 H Beam Fabrication Machine:

Technical Parameter | PHJ18 High Precision 3 in 1 I H Beam Assembly Weld Straighten Integral Machine |

Web Size | Height: 200 ∼ 1,800 mm; Thickness: 5 ∼ 30 mm |

Flange Size | Width: 200 ∼ 800 mm; Thickness: 6 ∼ 40 mm |

Workpiece (Welded H Beam) Length | 3,000 ∼ 15,000 mm (Can be tailor made) |

Working Speed of Assembly/ Welding Straightening | 200 ∼1,200 mm/min.; Working speed 500~700 mm/min. (Stepless, A.C. inverter control) |

Welding Seam | Single Pass of max. size 8~12 mm |

Finished Workpiece | Symmetric and Asymmetric Cross Section Shape Welding H Beam/ I Beam/ T Beam |

Machine Overall Dimension (L×W×H) | 28m × 4m × 4.8m |

Input and Output Conveyor | 10~11m length in 3 segments each; One with motor, two followers; Input conveyor with 3 sets of hydraulic pulling rod boxes |

Driving Mode | Assembly/ Straightening/ Output conveyor elevation: Hydraulic cylinder |

Welding Mode | Single Arc or Twin Arc SAW at fillet flat position |

Hydraulic System Working Pressure | 6~ 8 MPa |