A. Newly Designed Angle Steel Straightening Machine:

1) Up to now, the development of ASM series Angle Steel Straightening Machine has went thru two stages on its core design: The structure of top and bottom straightening rollers;

2) This product section is on the latest design of ASM series Angle Iron Straightener, taking ASM63 model as an example. As you can check from the attached first photo.

B. The New Design on ASM63 and Remaining Models of Angle Straightening Machine:

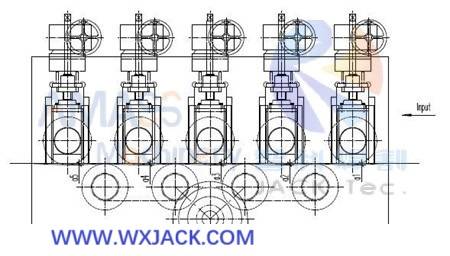

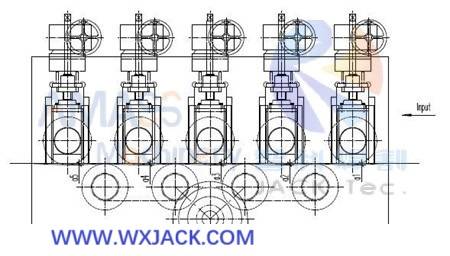

1. New Design: The design print on such new generation of Wuxi JACK ASM63 Angle Iron Straighten Machine please check the second photo. As shown in the print, the working cavity has five pieces of upper straightening rollers and four pieces of bottom straightening rollers:

Design print on working cavity of Wuxi JACK ASM machine: (Fig.1)

2. Old Design: Comparatively, mechanical main body of the first generation ASM63 model machine of Angle steel straightening please check the attached third photo. It has inverted arrangement of top and bottom straightening rollers: Four top and five bottom:

Previous design on arrangement of straightening rollers: Four top and five bottom: (Fig.2)

3. Reason on Upgrading Design in ASM Angle Straightening Machine:

So, why introduce such upgrade of arranging top and bottom position straightening rollers?

1) The problem with old fashioned design of four top and five bottom Straightening Rollers:

a) With certain period of track, study and analysis after initial development of the Angle Iron Straightener, we found such kind of structure in ASM series machine for Angle Steel Straightening has tendency of workpiece both ends tilting up --- You can imagine that checking at the third photo:

b) In ASM series Rolled Angle Straightening Machine, the bottom position straightening rollers are kept fixed along vertical direction, its solitary motion is revolving;

c) The top position straightening rollers descend down to exert pressing force on the Angle Steels;

d) So, if bottom straightening rollers “surround” the top ones in the process of Angle Steel straightening operation in the machine, the Angle Steels are relatively easily to be bent up at its both ends;

2) The Superiority in the New Structure of ASM Angle Iron Straighten Machine:

a) Comparatively, with the elevating upper straightening rollers “surround” the vertical stationary bottom rollers, it stabilizes the straightening process in the machine for Angle steel straightening, making sure the “squeezed” and “straightened” Angle Steels adjusted back to straight contour;

b) Please check attached video on workshop commissioning of the new generation ASM (This is a set of ASM130) machine of Angle steel straightening;

4. Comparison on New and Old Design of Angle Straightening Machine in Financial View:

1) The manufacturing cost and mechanical frame size of new and old design of ASM63 model machine of rolled Angle straightening is at the same level;

2) So, quotation of the two types of Angle Iron Straightener is also the same;

3) So is the running cost at customer site of the two type.

C. Straightening Cavity in ASM63 and Remaining Models of New Design Rolled Angle Straightening Machine:

1. Lateral view on new design machine of Angle steel straightening operation please check the attached 4th photo. You can find from it that each of the upper position straightening roller is connected with a piece of T shaped screw nut, with this screw nut driven directly with its overhead installed manual controlling worm gear reducer:

Front view on straightening cavity (Inside machine main frame) of Wuxi JACK ready to shipment ASM100 model: (Fig.3)

2. Upper straightening roller: In Wuxi JACK ASM models Angle Steel Straightening Machine, each of the upper straightening roller has its installation shaft coming through its center of circle, and assembled into both sides of wall board by means of bearing, which is secured from outside of wall board with a full circle of bolts, as you can find from the first and fourth photos;

3. When not in use, these critical working units of the machine for fulfilling rolled Angle straightening should be protected properly against external infiltration, as shown in the fifth and sixth photos:

Protect the machine against contamination control when not in use: (Fig.4)

4. Complement on Content of Angle Steel Straightening Machine:

1) For more information on main structure of the machine, please check product section of “High Velocity Automatic Longitudinal ASM160 Angle Steel Straightening Machine”;

2) For full configuration of the machine, please check product section of “Fast Speed Automatic Lengthways ASM130 machine for rolled Angle straightening”;

3) For safety and technical service of the machine, please check product section of “Efficient automated machine tool for acquiring on length direction Angle Iron straightening”.

D. Technical Parameters of ASM63 Angle Steel Straightening Machine:

Model Technical Parameter | New Design Good Effect ASM63 Rolled Angle Straightening Machine |

Min. Cross Section Size of Rolled Angle | 20 ×20×3 mm |

Max. Cross Section Size of Rolled Angle | 63 ×63 ×8 mm |

Length Range of Rolled Angle | 3000 ~ 9,000 mm |

Rolled Angle Straightening Speed | 6000 mm/min. |

Main Reducer Power | 5.5 kW, 1440 rpm |

Up Press Roller Adjusting Way | Manual Turning Handwheel |

Upper and Lower Straightening Rollers Interval | 393 mm |

Upper / Lower Straightening Rollers Quantity | 5/4 pieces |

Input Conveyor Length | One Segment, 5.8 m |

Output Conveyor Length | One Segment, 5.8 m |