A. Usage and Function of PFW1020 Four Torch Special Made Pipe Flange Welding Machine:

1. Purpose and Welding Mode: Pipe Flange Welding Machine, completes fabricating pipe and end flanges into finished working parts, in the welding mode of MAG or MIG;

2. Working Capabilities of the PFW1020 Pipe Flange Welding Equipment:

1) Summary: This Special Made Welding Machine is designed for performing welding two pieces of flange onto both ends of pipe with one time operation, by means of 2 pieces of welding torch working on the Circumferential Welding Machine at the same time:

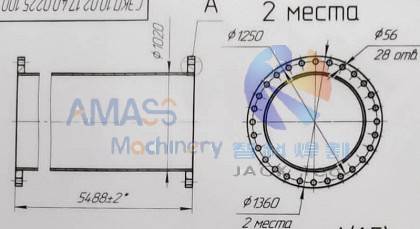

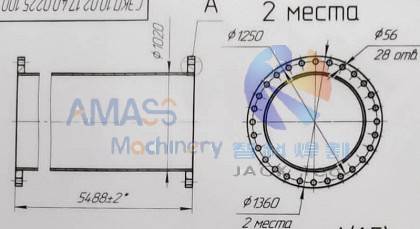

2) Pipe flange circumferential MAG welding in PFW1020 Pipe Flange Welding Machine: (Fig.1)

3) Welding Operation: Pipe and 2 pieces of flange are laid on to 2 sets of motor drive moving Welding Rotator. By means of rotation of its welding turning rolls, GMAW welding can be implemented in this Circumferential Welding Machine;

3. Main Working Steps in PFW1020 Pipe Flange Special Made Welding Equipment:

1) Based on actual length of pipe, the four sets of GMAW welding torch can be adjusted its position along the entire longitudinal length body of the pipe;

2) The motorized moving Welding Rotator serving as workpiece holding unit in the PFW1020 Pipe Flange Circumferential Welding Machine: (Fig.2)

3) Catering on Workpiece Specifications: With two sets of Welding Rotator supporting the pipe and can rotate in the welding speed (A.C. inverter adjust) of the Pipe Flange Welding Machine, the two sets of Welding Rotator also can adjust the longitudinal position for different pipe length, which is being fabricated in this Pipe Flange Welding Equipment;

4. Quantity of Welding Torches and Welding Seams Acquired from the Special Made Pipe Flange Circumferential Welding Machine:

1) This Special Made Welding Machine utilizes four sets of MAG welding torches, for fulfilling both ends flange welding onto pipe;

2) Each of the welding torch is equipped with 3 dimensional adjusting unit;

3) This Special Made Pipe Flange Welding Machine has 4 sets of welding oscillator units;

4) In this way, during operation of the Pipe Flange Welding Equipment, each of the welding torch can adjust its angular position, along X/Y axis two dimensional position easily.

B. Workpieces Applicable for PFW1020 Four Torch Special Made Pipe Flange Welding Equipment:

1. Specifications of Workpieces Designed for PFW1020 Pipe Flange Special Made Welding Machine:

Below is design drawing on workpiece intended for PFW1020 Special Made Pipe Flange Welding Machine: (Fig.3)

As shown in the above sketch:

1) The Max. external diameter of pipe is Φ1020mm;

2) The Max. internal diameter of flanges for mating is Φ1360mm;

3) The Max. length of finished pipe flange from the Pipe Flange Welding Machine can be 5500mm;

2. Welding Seams Completed from the Pipe Flange Special Made Welding Equipment:

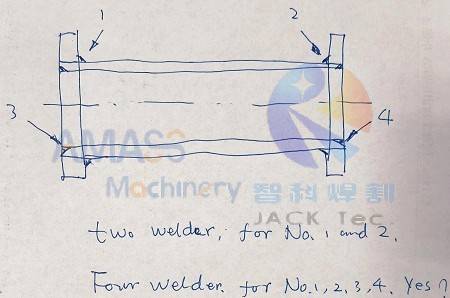

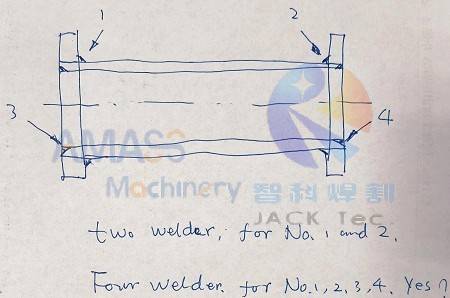

1) Welding seams confirmed by Wuxi JACK engineer with hand writing sketch for the Special Made Pipe Flange Welding Equipment: (Fig.4)

2) As shown in the above sketch, totally 4 pieces of circumferential seams at both ends of pipe flange mating can be acquired, in the form of flat fillet GMAW welding (MIG or MAG), from this Special Made Pipe Flange Welding Equipment;

3) Based on wall thickness of pipe and flange, welding current can be modulated conveniently for getting satisfactory performance of the Special Made Pipe Flange Welding Machine.

C. Main Configurations and Technical Performance of PFW1020 Four Torch Pipe Flange Special Made Welding Machine:

1. Welding Torches in the PFW1020 Special Made Pipe Flange Welding Machine:

1) There are totally 4 pieces of welding torches in this Special Made Welding Machine;

2) Each of the welding torch can be adjusted in 3-dimensional direction manually for point welding seam, totally 4 sets of manipulating systems;

3) Welding torch in the Pipe Flange Circumferential Welding Machine: (Fig.5)

2. GMAW Welding Power Supply in the PFW1020 Special Made Pipe Flange Welding Equipment:

1) Recommended Brand: MAG or MIG is Chinese HUAYUAN made NB-500HD model;

2) Specification: Welding current of the MIG/MAW machines is in the range of 80~500A, totally 4 sets;

3) Arrangement: The 4 sets of MIG/MAG welding machines are positioned at pipe both ends respectively: Each end 2 sets;

3. Detailed parameter of MAG welder for Pipe Flange Welding Machine: (Fig.6)

4. Workpiece Holding and Rotating Units in PFW1020 Pipe Flange Special Made Welding Machine:

1) Role: There are two sets of motor drive moving Welding Rotator in this Pipe Flange Welding Equipment, supporting and rotating pipe simultaneously;

2) Working Speed: Rotating speed of welding turning rolls is adjusted with A.C. inverter, which equals to actual MIG/MAG welding velocity in the Pipe Flange Circumferential Welding Machine, and is displayed in real time manner;

3) Longitudinal Adjustment: This supporting unit can adjust its longitudinal position according to pipe length, with railway fixed into workshop ground:

4) Rotating units in PFW1020 Special Made Pipe Flange Welding Equipment: (Fig.7)

5) Modulation: Each set of Welding Rotator has two pieces of turning rollers, which have handwheel to adjust roller distance according to pipe diameter. There are totally 2 sets of supporting unit in this Special Made Pipe Flange Welding Machine;

5. Welding Function Supplementary Units in PFW1020 Pipe Flange Special Made Welding Machine:

1) This Special Made Welding Equipment is equipped with four sets of ED-WLS40 model oscillator, a very valuable and convenient device;

2) This control device is directly connected to swing line accessing control box;

3) The swing unit is mounted onto running device, adjusting buttons being installed in control box:

4) Oscillator closed loop control circuit in the Pipe Flange Welding Machine: (Fig.8)

D. Welding Seam Tracing Unit in PFW1020 Pipe Flange Special Made Welding Equipment:

1. Strong Points of ED-WLS40 Oscillator in Pipe Flange Welding Equipment:

1) This is a special device for performing linear swing along workpieces, during welding in conventional and Special Made Welding Machine;

2) It is a small and light contrivance, easy to operate, having no operation place restrictions;

3) Welding oscillator in Pipe Flange Welding Machine: (Fig.9)

2. Technical Performance of Welding Oscillator in Pipe Flange Welding Machine:

1) Critical Indexes: Swings under digitally control/ Moving to center / Left and Right limit/ Swing speed management;

2) Action: Welding torch automatically returns to original center when stopping welding;

3) Characteristic: Extensive welding voltage range controlled with switch, not affected with input voltage;

3. General Operation on Oscillator in the Pipe Flange Circumferential Welding Machine:

1) Switch on power, its indicator light on;

2) Turn adjustment knob on panel of the oscillator;

3) For four swing modes, modulate two points stop time;

4) Adjust swing width and speed by turning knob;

5) During swing, check on actual torch swing in the Pipe Flange Welding Machine;

6) During operation, turn knob based on performance requirements of the Pipe Flange Welding Equipment if necessary;

7) At completion of welding, turn the oscillator to OFF position;

8) Welding torch automatically return to its original center position, thus completing task of oscillator for running Pipe Flange Circumferential Welding Machine.

E. Technical Specifications of PFW1020 Four Torch Pipe Flange Circumferential Welding Machine:

Below are main parameters of the Pipe Flange Special Made Welding Machine:

No. | Parameter | Specification | Note |

1 | Diameter Scope of the Pipe | Φ200 mm ~Φ1000 mm |

|

2 | Diameter Scope of the Flange | Φ300 mm ~Φ1360 mm |

|

3 | Applicable Pipe Length | 3000 mm ~5500 mm |

|

4 | Welding Speed (Rotating Linear Speed) | 100-1000 mm/min. | Inverter control, continuous stepless adjustment |

5 | Welding System Quantity | 4 Sets | Including: Welding torch/ Welding Power Supply/ Welding Supporting Unit |

6 | GMAW Welding System | HUAYUAN made NB-500HD (MAG or MIG) |

7 | Max. Welding Current | 500 A |

8 | Welding Oscillator | 4 Sets | Model ED-WLS40 |

9 | Welding Torch Adjust Unit | 4 Sets | 3 dimensional |

10 | Support Travelling Car | 2 Sets | Motor drive, along rail |

11 | Power Electricity | AC380V,50Hz,3P | Special Made available |