1. The Benefit of HB Series Automatic H Beam Production Line:

1) As introduced in product section of “HB1500 High Speed Semi Automatic Production Line”, the total investment on H Beam Production Machine in automatic line with SAW welder is 2 times that of semi-automatic line;

Then, under what circumstances that, customer choose automatic line instead of semi-automatic type? The 3 major factors behind that are:

1) Much Higher Production Efficiency of Automatic H Beam Production Line:

a) The productivity of automatic line is 2 ~ 2.5 times that of semi-automatic line;

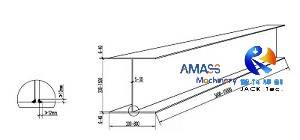

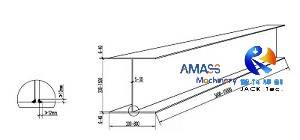

b) Production Efficiency: Based on calculation and feedback from customers over the years, with single shift of production, output of a complex of automatic H Beam production line is around 5,000 Ton on annual basis; While for a semi-automatic line, it is around 2,000 ~ 2,500 Ton per year: (Fig.1)

2) Upgrade on Customer Workshop with Automatic H Beam Production Line:

The 2nd benefit lies in modern and high end workshop embodied with a complex of automatic line for fulfilling welding H Beam production. It represents on strong strength of customer;

3) Labor Saving in Automatic H Beam Production Line:

The 3rd benefit is less operators involved. H Beam Production Machine in a typical group of automatic line usually needs 7 ~ 8 operators to take care:

a) 1 Operator for CG4000 CNC Strip Plate Cutting Machine;

b) 1 Operator for H Beam Assembly Machine with tack welding;

c) 4 Operators for 4 sets of LHC SAW H Beam Gantry Welding Machine;

d) 1 Operator for HYJ800 H Beam Straightening Machine;

e) 1 Operator for hoisting flange and web from plate cut to assembly, and back up;

No operator needed for working on transferring H Beam among workstations inside the automatic line for H Beam production .

2. Layout of Automatic Welding H Beam Production Line at Customer Site:

When introducing automatic line, the second factor is its land occupation. Please check attached second picture on layout of typical line. Standard arrangement is:

1) General Structure of Automatic H Beam Production Line:

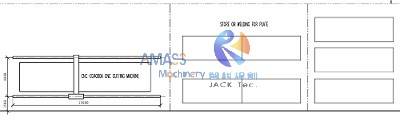

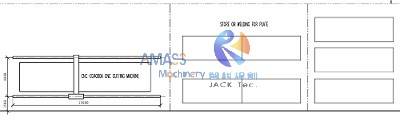

a) H Beam Assembly Machine, H Beam Gantry Welding Machine and H Beam Straightening Machine lay in a streamline following one after the other: (Fig.2)

b) Alongside this flow line of the three H Beam Production Machine, in parallel is CNC Strip plate cutting machine and raw material (Carbon steel plate) storage area for automatic H Beam production: (Fig.3)

2) Overall Space Occupation of Automatic I Beam Production Line:

a) Required Area: The total length from starting point of input conveyor of H Beam Assembly Machine, to the end point of output conveyor terminal of H Beam Straightening Machine should be 95m at minimum, or 120m better, or 200m the best with margins and spare back up zone considered;

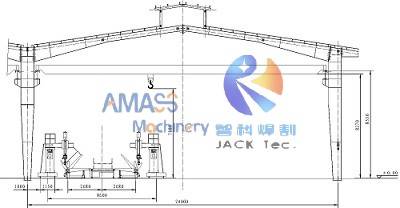

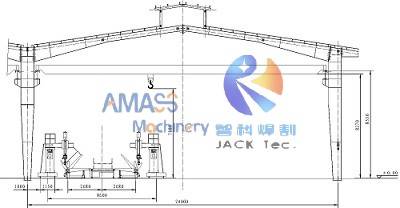

b) There are two bays of span in one complex of Automatic Welding H Beam Production Line;

c) The width of one span of flow line is 11m. Plus 2m walking passage, and another 11m span for cutting machine and storage, total width of facility should be at least 22m;

d) Height of travel crane overhead for hoisting flange and web from CNC Strip Plate Cutting machine onto H Beam Assembly machine should be 8.6m high. Shown as below: (Fig.4)

3) Occupied Area: In All, a typical Automatic Welding H Beam Production Line needs floor area of at least 24m (width) x 95m (length) to better 24m (width) x 120m (length) to suggestive 24m (width) x 200m (length), with height of 12m (8.6m height for travel crane beam) for accommodating H Beam Production Machine.

3. Technical Parameters of HB Series Automatic H Beam Production Line:

Model | HB Series Automatic Welding H Beam Production Line |

Max. H Beam Web Width | 1500 / 1800/ 2000 mm |

H Beam Web Thickness | 6∽32 mm |

H Beam Flange Width | 200∽800 mm |

H Beam Flange Thickness | 6∽40 mm (Special thickness of 40~80mm also available) |

H Beam Length | 4000 ∽ 12000 mm |

Max. H Beam Weight | 20 Ton. |

Total Land Occupation of Automatic Line | (95~ 120~ 200 m Length) x (24m Width) x (8.6m Height) |

H Beam Assembly Station | Z15/Z18/Z20 H Beam Assembly Machine with Tack Welding |

H Beam Welding Station | LHC model H Beam Gantry Welding Machine |

H Beam Straightening Station | HYJ40/800 H Beam Straightening machine |

Transfer of H Beam workpiece among stations | With Flipping units/ Conveyor/ Travel Cart |