1. Outline on Working of PR24 Model Small Medium duty Pipe Welding Rotator:

1) Usage: From the previous product section, we can understand that PR series product is a kind of dedicated Pipe Rotator for welding, attaining workpiece optimum welding orientation, by means of the rotation and tilting in this Pipe Welding Positioner;

2) Model: PR24 is for processing on small medium diameter pipe and tube members.

2. Main Technical Specifications of PR24 Model Small Medium duty Pipe Welding Positioner:

1) Applicable Workpieces:

As a model of Small Medium duty Pipe Rotator for welding, the fitting workpieces of pipe, tube, elbow for PR24 is within diameter range of 60mm ~ 800mm, fairly extensive scope;

2) Three Core Working Steps:

a) Revolving speed of the bottom turning rollers, which is the circumferential welding speed of workpiece in the Pipe Welding Rotator, is adjustable within the boundary of 0.09~0.9 rpm, controlled with A.C. inverter;

Close view on pipe rotation: (Fig.1)

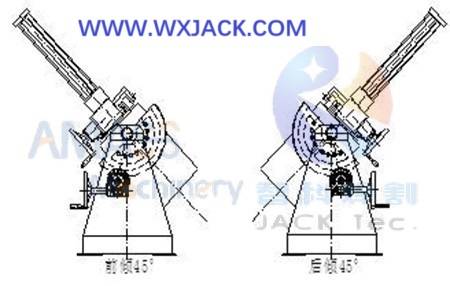

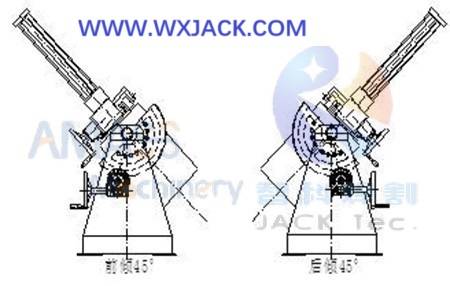

b) Worktable Tilt: This PR24 model Small Medium duty Pipe Weld Positioner has the 2nd motion of worktable table tilting, or swing, around radial axis of workpiece, in constant angular velocity of 1.2rpm, to and from within the range of -45°~+45°;

Tilt of worktable and pipe: (Fig.2)

c) Downward Stroke: Before welding operation in this Pipe Welding Positioner, the top downward press turning roller elevates within the up and down stroke of 510mm, in the speed of 245mm/min. under motor drive, so that all the diameters of workpiece within rated specification can be held firmly for reliable running and circumferential welding;

Downward press roller: (Fig.3)

3) Overall Dimension of Equipment: This PR24 model has overall dimension of 1.85m height by 1.27m length by 0.87m width, taking very small space occupation. You can easily find a small place for locating it in workshop.

3. Structure of PR Series Motor drive Pipe Rotator for Welding:

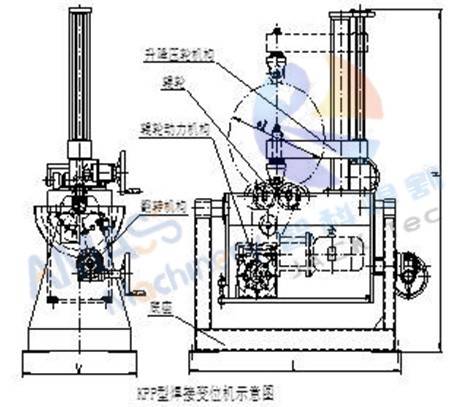

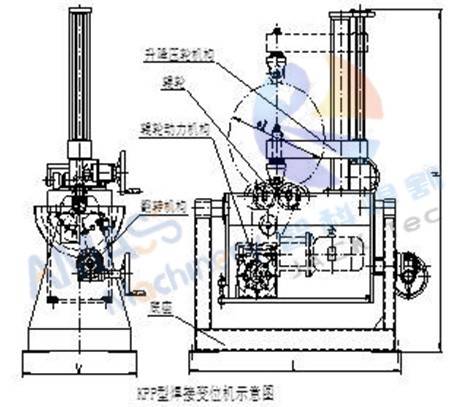

The PR series Pipe Welding Positioner has main units of Base Bed, Revolving unit, Tilting unit, Pressing unit, and Control system. Please see below sketch:

Design sketch on structure of the equipment: (Fig.4)

1) Base Bed of Pipe Welding Rotator:

a) This is the supporting base and work table of the Pipe Weld Positioner;

b) The remaining units of the equipment are all installed on it;

c) The mechanical base bed is welded into the frame shape with steel plates and channels, and machined again after annealing. It has strong rigidity and shock resistant capability, serving as solid base for operation;

2) Workpiece Revolving Unit in Pipe Welding Rotator:

Close view on pipe elbow revolve mechanism: (Fig.5)

Working revolving unit is composed of 2 sets of bottom turning rollers, as well as its driving and transmission system: Motor reducer, together with chain and sprocket;

3) Work Table Tilting Unit in Pipe Welding Positioner:

a) Tilting, or swing of the workpiece for welding is fit on the wall boards of bed;

b) This tilting operation is driven with motor reducer, and transmitted with gear sector. See below sketch;

Design sketch on work table tilt unit: (Fig.6)

4) Workpiece Pressing Unit in Pipe Welding Rotator:

The tube, pipe, elbow pressing mechanism is for the purpose of:

a) Holding workpiece firmly onto the bottom turning rollers;

b) Increasing friction force between the workpiece and turning rollers;

c) Making smoother revolve of the workpiece;

d) Guaranteeing no slippage of the workpiece during its tilting;

In this Pipe Welding Positioner, position of the press turning roller, or its downward stroke, is adjustable for accommodating pipe, tube, elbow with different diameters;

5) Electric Control System of Pipe Welding Positioner:

Electric control system consists of control elements of Breaker, inverter, contactor, relay, as well as control cabinet and operating panel;

6) We will go on with topic of drive and transmission of the PR series pipe welding equipment in the next product section of PR40;

7) Supplementary Notes on PR Series Pipe Welding Positioner:

a) PR series is a very special type of Welding Positioner, specifically applied for pipe, elbow and flange welding;

b) If you have interest on the common seen product, please check product sections of

Single Table Top standard Welding Positioner;

L type Welding Positioner;

Head and Tail Welding Positioner.

4. Technical Parameters of PR24 Model Pipe Welding Positioner:

PR24 Small Medium duty Pipe Welding Positioner |

Applicable Workpiece Diameter Range | 60~ 800mm |

Revolving Linear Speed of Turning Roller | 0.09 ~ 0.9 rpm |

Turning Roller Revolving Range | 0° ~ 360° |

Turning Roller Tilting | -45° ~ +45° range, 1.2 rpm angular speed |

Top Turning Roller Downward | 510mm Stroke, 245 mm/min. speed |

Equipment Overall Dimension | 1.85m Height x 1.27 Length x 0.87m Width |