A. Technical Specialties, Usages and Application of SXBJ-15 Automatic Large Stroke Steel Plate Edge Milling Machine:

1. Function and Usage of SXBJ-15 Automatic Large Stroke Steel Plate End Milling Machine:

1) Function:

a) As shown in the attached photos and below small picture, this SXBJ-15 model double heads sheet metal plate Edge Beveling Machine has effective long stroke of 15,000 mm, for making welding grooves on top and bottom edges of workpiece metal plates:

b) The top, straight and bottom edges beveled into X shape groove on a piece of long steel plate, produced from Wuxi JACK SXBJ-15 model automatic large stroke machine for steel plate edge chamfering: (Fig.1)

2) Usage:

a) With two sets of 7.5kW milling head installed on its motorized moving carriages, this double heads Large Stroke Steel Plate Edge Milling Machine fulfils task of welding groove making on upper/ lower/ straight/ slant edges of workpiece steel plate, in the working mode of milling facer blade in high speed revolution:

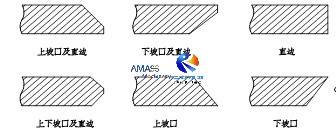

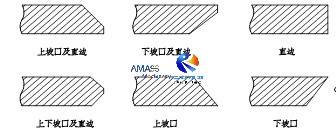

b) The common types of welding grooves that can be made in XBJ and SXBJ series equipment for steel plate end beveling: (Fig.2)

c) High speed revolving facer blade is making bottom chamfer on steel plate in Wuxi JACK SXBJ-15 model automatic large stroke machine of steel plate edge beveling: (Fig.3)

2. Technical Characteristics of Large Stroke Steel Plate Edge Beveling Machine:

1) The mechanical working table and body of SXBJ models double heads Large Stroke Steel Plate End Beveling Equipment should guarantee on its rigidity and precision uniform along the entire length of edge milling stroke;

2) This is the precondition for making sure long term successful running of the SXBJ-15 and other models of large stroke machine for edge milling;

3) Process Route on making mechanical bed of machine for edge milling: For this purpose, the mechanical body of Wuxi JACK XBJ and SXBJ series sheet metal plate End Milling Machine are made from high quality mild steel, with its size and thickness in fully sufficient specification, fabricated into subassemblies, and then went through advanced level heat treatment to have stress relieved, and precisely controlled for final assembly. Check below photo:

4) Mechanical working table of Wuxi JACK SXBJ-15 model large stroke machine for steel plate edge milling: (Fig.4)

3. Application of SXBJ-15 Large Stroke Steel Plate Edge Chamfering Machine:

1) Applicable Applicating Sites:

a) The attached pictures show a set of Wuxi JACK SXBJ-15 model machine of edge milling, being applied in a Shipyard facility;

b) The other working sites where Large Stroke Steel Plate End Milling Machine, including SXBJ-15 here, and SXBJ-125 model, and SXBJ-18 model, are often selected by customers, include Port Machinery plant, Bridge Construction, Power Plan, etc.;

c) A set of Wuxi JACK SXBJ-18 model large stroke machine of steel plate edge milling is being operated at a Shipbuilding customer facility: (Fig.5)

2) Why Need Plate End Beveling Equipment in large scale working sites?

a) Purpose: In the field of Large Machinery Production and Large Projects Construction, one of the indispensable steps at its beginning of process route, is to have welding and fabricating on large size (Length and width), thick thickness, and heavy weight metal plates, especially steel plates;

b) To get a eligible welding seam on these steel plates, especially with thickness thicker than 15mm, welding grooves of 0° ~90° angular scope, the majority close to 45°, should be made on edges of these steel plates, by means of XBJ single head and SXBJ series double heads Edge Milling Machine;

c) A piece of 100mm thick steel plate is being edge chamfered, in Wuxi JACK SXBJ-15 model Large Stroke Steel Plate Edge Chamfering Machine: (Fig.6)

B. Technical Introduction on SXBJ-15 Large Stroke Steel Plate End Milling Machine:

1. Foundation Making and Installation of Edge Milling Machine:

1) Wuxi JACK provides to customers foundation drawing before delivery, and customer can make foundation based on it;

2) The most important control point during installation of machine of edge milling operation, is for adjusting its mechanical bed levelness;

2. Adjust levelness of the End Milling Machine Mechanical Bed:

At the completion of Edge Milling Machine foundation making, the levelness adjustment on its working table is carried out based on the below standards of:

1) Levelness of the entire worktable length of the machine for edge milling, should be within the tolerance of 0.8 mm/m;

2) Parallelism between Edge Chamfering Machine worktable and pressing beam, should be controlled within the tolerance of 0.6 mm/m;

3) Linearity along the whole length of machine for end milling operation worktable, as in the case of this SXBJ-15 large stroke machine for edge milling, which is 16m, should be controlled within the tolerance of 0.5 mm/ 15m;

3. Only after the above mentioned adjustments completed during installation and adjustment on the Steel Plate Edge Beveling Machine, can the bolts for securing connection between worktable and pressing beam being tightened;

4. Following that, make the second time cement pouring for the plate End Beveling Equipment installation;

5. After curing time of the second time cement pouring, tighten mechanical body and loading racks of the machine for steel plate edge milling, by means of anchor bolts.

C. Technical Parameters of SXBJ-15 Double Heads Large Stroke Steel Plate Edge Milling Machine:

Model Technical Parameter | SXBJ-15 Double Heads Large Stroke Steel Plate End Milling Machine |

Steel Plate Edge Milling Max. Length Stroke | 15,000 mm |

Steel Plate Edge Milling Width Range | 600 ~ 3000 mm |

Steel Plate Edge Milling Thickness Range | 6∼ 100 mm (Based on customer demand) |

Quantity of Hydraulic Drive Pressing Jacks | 25 Pieces |

Edge Milling Head Quantity | 2 Sets |

Edge Milling Angle Range of Top Milling Head | 0° to +80° |

Edge Milling Angle Range of Bottom Milling Head | -45° to 0° |

Power and rpm of Edge Milling Head | 7.5 kW, 1440 rpm (Higher Power available) |

Spindle rpm of Edge Milling Head | 75 ~ 420 r/min., 6 grades by handwheel |

Hydraulic Power Motor | 5.5 kW |

Taper Hole of Milling Spindle End | ISO 50 (7:24) |

Milling Head Spindle Stroke | 100 mm |

Edge Milling Working Speed | 150∼1000 mm/min. Stepless controlled with A.C. inverter |

Idle High Speed of Milling Head and Moving Carriages | Fixed 4000 mm/min. |

Applicable Diameter of Facer Blade | D=Ø125 ~ Ø320mm (Ø200mm for making delivery) |

Quantity of Hydraulic Jack Screw | 4 sets, intermittently installed |

Edge Milling Machine Worktable Width | 550 mm |

Worktable Height | 1050 mm |