Uniqueness of Plate Triple Cutting Machine:

1) As a branch of CNC Flame Cutting Machine, Oxygen-fuel flame Plate Triple Cutting Machine uses oxygen and oxyacetylene as its cutting gas for making chamfering on edge of carbon steel plates;

2) So, this branch of CNC Cutting Machine is also named as Plate Flame Triple Cutting Machine.

1. Brief on Triple Flame Cutting Machine:

1) Usage of the Oxygen Fuel Flame Plate Triple Cutting Machine:

a) Function and Delivery: Plate Triple Cutting machine is for making edge beveling on sheet metal steel plate, especially carbon steel plates, as you can observe from the attached second and third photos;

b) Counterpart: In this respect, plate Triple Flame Cutting Machine has similar usage as Plate Edge Milling Machine, but works in different principle;

Wuxi JACK CNC-CG5000 Plate Triple Cutting Machine in trail run at customer workshop:

(Fig.1)

Finished beveled carbon steel plate from Triple Flame Cutting Machine: (Fig.2)

2) Working Principle of Sheet Metal Plate Triple Flame Cutting Machine:

The difference between triple CNC Flame Cutting Machine and Plate Edge Milling Machine lies in working principle:

a) The Plate Edge Milling Machine makes chamfering on edges of workpieces, in the way of high speed milling head (Mechanical type);

b) While this CNC-CG series flame triple CNC Cutting Machine makes beveling on edges of workpieces, by means of triple flame cutting in the speed of flame plate cutting;

3) Versatile Working Model of Triple Cutting Torch in Plate Flame Triple Cutting Machine:

a) As shown in the attached photos: In Plate Triple Cutting Machine, one piece of triple cutting torch has three pieces of single cutting head;

b) From triple cutting to single cutting: Shut off the two pieces of lateral heads of the triple cutting torch, and only leaving the middle one cutting head on, the triple cutting torch is turned into single or strip cutting torch;

c) In this sense, Plate Triple Flame Cutting Machine covers function of Strip Plate Cutting Machine, with only less quantity of cutting torch and hence productivity;

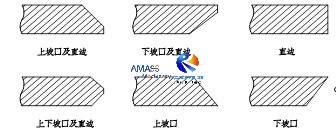

4) Bevels and Chamfers to be Made from Triple Flame Cutting Machine:

a) The typical and classical types of chamfers that can be made with this CNC-CG series Flame Plate Triple Cutting Machine are X/ Y/ K/ V, shown in below sketch:

The most often selected bevels to be expected from Plate Triple Cutting Machine: (Fig.3)

2. Structure and Technical Features of Plate Triple Flame Cutting Machine:

1) Structure of the CNC Cutting Machine:

The Plate Triple Flame Cutting Machine derives from "standard" CNC Flame Cutting Machine. It has the basic structure of motor drive gantry moving along two parallel cutting rails;

2) Application of the CNC Flame Cutting Machine:

a) Configuration: The picture attached shows a set of Wuxi JACK CNC-CG5000 Plate Triple Cutting Machine, which is installed with two piecess of triple cutting torches. Such triple CNC Cutting Machine belongs to the type of tailor made configuration;

b) Uniqueness of the CNC Triple Flame Cutting Machine: This is not the often adopted configuration in CNC Flame Cutting Machine: Triple cutting is more frequently seen as integrated with CNC single torch cutting and strip cutting, to give the CNC Cutting Machine more choice of function and operation;

3) Drive Control in the CNC-CG5000 Sheet Metal Steel Plate Triple Flame Cutting Machine:

a) CNC is a not must traditionally: Conventional Plate Triple Flame Cutting Machine does not have requirement on contour control. So, CNC is not a must for its controlling system;

b) Importance of Double Drive: However, for all kinds of ordinary (Which means, no CNC control and servo drive) and CNC Cutting Machine, rail span above 4,000mm means double drive CNC Cutting Machine should be introduced for the purpose of stable running, which can only be realized with servo driving and accordingly CNC control;

c) CNC control role here: This is true for the CNC-CG5000 Plate Triple Cutting Machine shown in the attached pictures: It has the rail span of 5,000mm. To guarantee the CNC Cutting Machine performance and its cutting quality, CNC and corresponding servo driving systems are adopted, upgrading the CNC Cutting Machine a set of genuine sense CNC control Plate Triple Flame Cutting Machine;

d) Single Drive: On the other hand, to save cost for customers, "smaller" and more compact models of Plate Flame Triple Cutting Machine, which has parallel cutting rail span 4,000mm and less, does not obligely need CNC and servo driving, when there is no other special requirement on the Triple Flame Cutting Machine from customers.

3. Application and Operation of the Triple Flame Cutting Machine:

1) Assistant Step: There will be dregs and residues left on the bevels of steel plates, which are cut with Plate Triple Cutting Machine. So, it needs to be knocked off as trimming operation;

2) Cutting Angle Accuracy Control in Plate Triple Cutting Machine:

a) The correctness and accuracy of bevels made with Plate Flame Triple Cutting Machine depends on adjustment of swing angles of the two pieces of lateral cutting heads;

b) For this purpose, There is an indicating ruler on each of the lateral cutting heads for management on the cutting torch swing angle;

3) 2 options on triple and single flame cutting: As mentioned in item one, in Flame Plate Triple Cutting Machine, turning off the two lateral cutting heads, the middle one head can be used for strip cutting;

4) Thermal cutting gas adjustment: Cutting gas pressure and flowrate management is same as standard flame plate cutting of single head cutting torch in standard CNC Flame Cutting Machine;

Gas regulating panel in Wuxi JACK CNC Flame Cutting Machine: (Fig.4)

4. Technical Parameters of Plate Triple Flame Cutting Machine:

Below are technical parameters of this High Speed CG5000 CNC Plate Triple Flame Cutting Machine (CNC Flame Cutting Machine):

High Speed CG5000 CNC Plate Flame Triple Cutting Machine (Plate Triple Cutting Machine) |

Flame Cutting Rail Span | 5000 mm |

Max. Work Piece Width | 4200 mm |

Flame Cutting Railway Length | 15000 mm |

Max. Work Piece Length | 13000 mm |

Drive for Gantry Movement | Double Size with Servo motors |

Min. to Max. Beveling Thickness | 16 ~ 80 mm |

Min. to Max. Single Cutting Thickness | 6 ~ 150 mm (Special made for 200mm) |

Min. to Max. Beveling and Cutting Speed | 100 ~ 1000 mm/ min. |

Bevels that can be Made | X/ Y/ K/ V |