A. The Uniqueness and Usage of Iron Hand Assistant SXBJ-4 Double Heads Plate Edge Milling Machine:

1. The Two Most Distinguished Features of SXBJ-4 Double Heads Plate End Beveling Machine:

1) 2 sets of machine as an Integrity: This Welding Groove Making Equipment working group consists of 2 sets of SXBJ-4 double heads configuration machine for plate beveling, working as an unity:

2) Iron Hand for Material Transferring: The material handling between the 2 sets of double heads equipment of plate welding groove making is realized by means of 0° ~ 180° swing manipulator, instead of conventional standing racks, which is the default setting in XBJ and SXBJ series Steel Plate Edge Milling Machine;

3) On Site Operation: The swing of iron hand (Manipulator) between the 2 sets of Wuxi JACK SXBJ-4 Double Heads Plate Edge Chamfering Machine at customer facility: (Fig.1)

2. Usage and Application of the SXBJ-4 Double Heads Plate Welding Groove Making Equipment:

1) Applicating Case: This product section of the SXBJ-4 double heads configured machine for plate edge milling is designed and produced specifically by Wuxi JACK, for being deployed in a highly efficient TAKT Port Machinery manufacturing flow line;

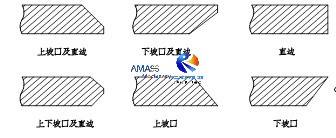

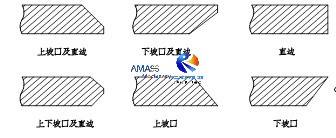

2) Task: The function of this working group of Iron Hand Assistant SXBJ-4 Welding Groove Making Equipment is to complete on groove milling on both sides of workpiece steel plate, in the form of up/ straight/ lower edges beveling;

3) The designed X/ V/ K grooves on edges of steel plate, that can be made from SXBJ-4 Double Heads Plate Beveling Machine: (Fig.2)

4) The working moment of Wuxi JACK iron hand swing SXBJ-4 double milling heads machine for plate edge milling at customer site: (Fig.3)

B. General Working Steps of Manipulator Acting SXBJ-4 Double Heads Plate Edge Milling Machine:

1. 0° ~ 180° Swing Manipulator in the Working Group of SXBJ-4 Plate Edge Chamfering Machine:

1) As shown in the attached picture and below, to adapt to logistics requirement of the production line, this SXBJ-4 double heads equipment for welding groove making is equipped with a group of manipulators at its front side;

2) This group of iron hand replaces the standard configuration of extension racks for performing loading of workpieces, in the XBJ and SXBJ models Sheet Metal Edge Milling Machine;

3) The 0° ~ 180° swing manipulator between the 2 sets of Wuxi JACK SXBJ-4 double milling heads machine for edge milling: (Fig.4)

2. One Way Flow of Workpiece Steel Plate through the Working Group SXBJ-4 Double Heads Plate End Beveling Machine:

1) Another disparity with operation of this machine of edge chamfering is its one way flow of workpiece, instead of the original two ways transporting workpiece steel plate into and out of the equipment for welding groove making, as in the case of general purpose standard type XBJ and SXBJ series Edge Milling Machine;

2) This is also determined by specialty of the manufacturing flow line, as shown in the attached and below photos taken at customer site:

3) The material steel plate flow through the Wuxi JACK SXBJ-4 Double Heads Plate Edge Milling Machine: (Fig.5)

3. Working Principle and Sequence of Iron Hand Manipulator in the SXBJ-4 Double Heads Plate End Beveling Machine:

1) Style: As shown in the attached and below photo, the manipulator is in the concrete structure of rocking arm, which is composed of group of rollers;

2) Swing Scope: This pair of rocking arm can revolve within the range of 0°~ 180° under motor drive, between the machine of end beveling;

3) Flat Position: When this group of SXBJ-4 machine of edge milling is not in working, the manipulator has its rocking arm lying in the flat horizontal position, serving as input conveyor of the workpiece into the Welding Groove Making Equipment;

4) Erected Position: After the workpiece steel plate is sent into the Plate End Beveling Machine for making welding groove, the manipulator has its rocking arm risen up to 80° (As is shown in the attached picture), leaving sufficient space for the two sets of edge milling carriages producing welding groove in the machine of edge milling;

5) Working Moment: The 80° rising up of iron hand manipulator rock arm ahead of the Wuxi JACK SXBJ-4 double milling heads machine for plate edge milling: (Fig.6)

6) Back to Flat Position: At the completion of plate edge milling in this group of SXBJ-4 model machine of plate edge milling, the workpiece steel plate goes forward and out of the machine for plate edge chamfering operation, and is sent to subsequent station in the manufacturing line, including RH2000 Edge Rounding Machine, by way of conveyors;

7) Ready for Next Round: By this time, the manipulator has its rocking arm falling down again, ready for the next round of making welding groove in this working group of machine of edge milling.

C. Technical Parameters of Manipulator Assisting SXBJ-4 Double Heads Plate Edge Milling Machine:

Model Technical Parameter | Iron Hand SXBJ-4 Double Heads Plate End Beveling Machine |

Steel Plate Max. Edge Milling Length | 4,000 mm / Set |

Steel Plate Edge Milling Width Range | 600 ~ 3,000 mm / Set |

Steel Plate Thickness Range for Sheet Metal Edge Chamfering | 6∼50 mm (Based on customer demand) |

Milling Head Quantity | 2 Pieces/ Set |

Milling Angle Scope of Top Milling Unit | 0° to +80° / Set |

Milling Angle Scope of Down Milling Unit | -45° to 0° / Set |

Quantity of Oil Cylinder Drive Jacks | 8 Pieces/ Set |

Power and rpm of Milling Head | 7.5 kW, 1440 rpm (Higher Power available) |

Spindle rpm of Edge Milling Head | 75 ~ 420 r/min., 6 grades adjusted by turning speed lever |

Hydraulic Power Motor | 5.5 kW / Set |

Milling Unit Feeding Motor | 2.2 kW / Set |

Milling Unit Lifting Motor | 1.1 kW / Set |

Edge Milling Speed | 150∼1000 mm/min. Stepless |

Idle High Speed of Edge Milling Head | 4000 mm/min. |

Applicable Diameter of Facer Plate | D=Ø125 ~ Ø320mm (Ø200mm For delivery) |

Worktable Width | 450 mm |

Worktable Height | 1050 mm |

Rocking Arm Roller Manipulator | 1 Group, 0°~180° / Set |