The attached photos were taken at different steel structure facilities across the globe and regions, on different design of LHA series H Beam Gantry Welding Machine produced by Wuxi JACK for worldwide customers.

1. The Application and Characteristic of LHA series Gantry type H Beam Welding Machine:

1) As introduced in the product category of automatic Gantry type I Beam Submerged Arc Welding Machine, this equipment is the second set of core H Beam Production Machine following H Beam Assembly Machine, and also the most important one: The welding H Beam output from this machine is already finished product. The H Beam Straightening Machine following it is for dressing the welded H Beam;

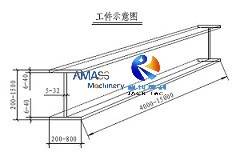

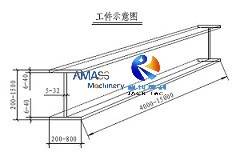

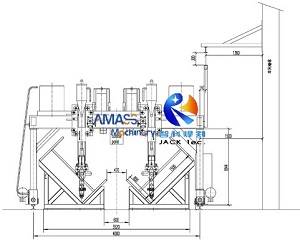

2) This series of Gantry type H Beam SAW Machine performs 45° fillet position submerged arc welding (short for SAW) on the assembled and tack welded H Beam made with the H Beam Assembly machine. For each piece of H Beam, there are four pieces of seams to be welded, see below sketch: (Fig.1,2)

2. Classification of LHA series Gantry type H Beam Welding Machine and Distribution in Application:

1) Also, as introduced, depending on variety in structure of machine frame, the H Beam Production Machine of Gantry type H Beam Welding Machine has three general types of:

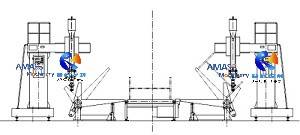

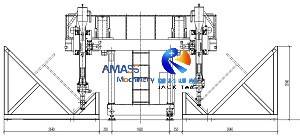

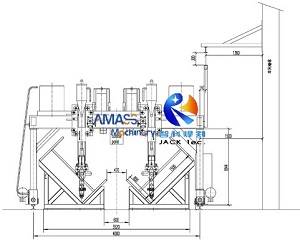

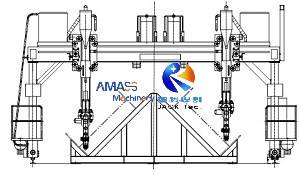

a) Gantry type H Beam Gantry Welding Machine --- LHA series, including LHAZ and LHAC; (Sketch see below)

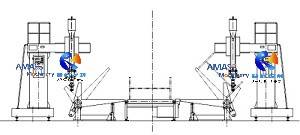

b) Column type I Beam Submerged Arc Welding Machine --- LHC series: (Fig.3)

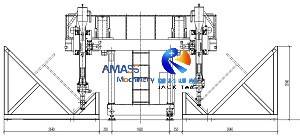

c) T type H Beam SAW Machine --- LHT series: (Fig.4)

2) Of which the gantry type LHA H Beam Gantry Welding Machine sees the widest application. It can not only be used in semi-automatic H Beam production line, but also work as individual independent automatic H Beam Production Machine for performing SAW on workpiece;

3) Due to the feature of its frame structure, the LHA Gantry type H Beam Welding Machine is not applicable to be applied in automatic H Beam production line.

2. Structure Brief and Disparity in LHA series H Beam Gantry Welding Machine:

1) Each set of automated LHA Gantry type H Beam Welding Machine has two welding stations installed on its gantry frame;

2) And, based on position of operator, this LHA Gantry type I Beam Submerged Arc Welding Machine has two sub categories of center control (LHAZ) and side control (LHAC) Gantry type H Beam SAW Machine. Please check below sketches to compare:

a) Center control (LHAZ) high efficiency H Beam gantry welding machine: (Fig.5)

The standard models of LHAZ Gantry type H Beam SAW Machine include LHA4Z, LHA5Z, LHA55Z;

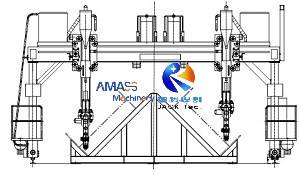

b) Side control (LHAC) high efficiency H Beam gantry welding machine: (Fig.6)

The standard models of LHAC Gantry type H Beam SAW Machine include LHA4C, LHA5C;

3) We can see that the LHAZ model H Beam Gantry Welding Machine needs only one operator to take care the SAW process during work, while LHAC H Beam Gantry Welding Machine needs two operators to work on the machine;

4) On the other hand, for welding H Beam of same size (Especially large size bigger than 1500mm height), the LHAZ model Gantry type H Beam Welding Machine has larger size of gantry compared with that of LHAC: As a summary, each type of these high quality Gantry type H Beam SAW Machine has its strong points and weak points.

5) Based on that, when purchasing LHA series H Beam Gantry Welding Machine, customer can choose the most fitting type based on your preference.

3. Technical Parameters of LHA series H Beam Gantry Welding Machine:

Each model of the product has its personalized specifications and parameters. Below are general specifications range of this series of H Beam Production Machine on LHA high precision Gantry type H Beam Welding Machine:

LHA series I Beam Submerged Arc Welding Machine (Gantry type H Beam SAW Machine) |

Parameter | Specification | Note |

SAW Welding Position | 45° fillet welding |

|

SAW Welding Velocity (mm/min.) | 240 ~ 2400 | Controlled with A.C. Inverter |

Idle High Speed (mm/min.) | 3200 |

|

H Beam Flange Width (mm) | 200 ~ 800 |

|

H Beam Flange Thickness (mm) | 6 ~ 40 |

|

H Beam Web Height (mm) | 200 ~ 2000 | Differs on specific model |

H Beam Web Thickness (mm) | 6 ~ 32 |

|

H Beam Length (mm) | 4000 ~ 15000 |

|

Max. Gantry Span (mm) | 5500 | Differs on specific model |

Gantry Travel Rail Length (mm) | 18000 |

|