A. Property and Usage of Open Structure SXBJ-15 Sheet Metal Plate Edge Milling Machine:

1. The “Open Structure” for SXBJ-15 Sheet Metal Plate End Chamfering Machine:

1)“Open structure” means, looking at this End Beveling Machine from lateral side, the entire set of machine for sheet metal plate end chamfering is like a piece of large size straight line wall board;

2) So, all the function units of the Edge Grooving Machine are installed at open area, instead of in enclosed zone. This is the conventional standard structure of machine for edge milling operation;

3) Comparatively, there is a kind of semi-closed structure Sheet Metal Plate End Beveling Machine, which is usually applied in small to medium size model, such as XBJ-6 model machine of edge milling task;

4) The SXBJ-15 model here belongs to double heads long stroke Edge Milling Machine, which is widely applied in large scale project and construction site, for carrying out large plates fabrication, especially big thickness;

2. Usage of SXBJ-15 Open Structure Sheet Metal Plate End Beveling Machine:

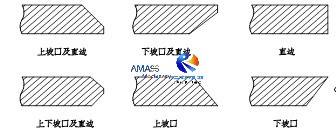

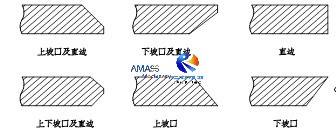

1) This SXBJ-15 model machine of sheet metal plate beveling job is for machining welding grooves on edges of metal plates, into below types of finished bevels: (Fig.1)

2) The max. length of metal plate that can be beveled in this SXBJ-15 Sheet Metal Plate Edge Grooving Machine is 15000mm;

3) The max. thickness and width of metal plate in the machine of edge milling is up to customer decision, which is usually in the range of 6mm to 60mm thickness for standard specification, and 2500mm max. width. Customer can denote these parameters;

4) Milling Angle: Milling Angle of the XBJ series Edge Milling Machine is also denoted by customer. We will equip the corresponding milling head based on customer demand. The most often selected range for edge milling angle scope in machine is 0~° 45°; The wider type is 0~° 80° in special equipped model machine of end beveling;

5) The 0~° 45° milling head equipped in Wuxi JACK SXBJ-15 model Sheet Metal Plate End Beveling Machine: (Fig.2)

6) The 0~° 80° milling head equipped in Wuxi JACK SXBJ-15 model machine for sheet metal plate end chamfering task: (Fig.3)

B. Technical Features of Open Structure SXBJ-15 Double Heads Sheet Metal Plate Edge Milling Machine:

1. Please check attached pictures and below. Typical configuration and structure of standard structure double heads configuration machine for sheet metal plate edge grooving operation (machine of edge milling):

2. Front Side View on mechanical frame of the Wuxi JACK SXBJ-15 model Open Structure Sheet Metal Plate Edge Grooving Machine at assembly workshop: (Fig.4)

3. Technical Specifications of SXBJ-15 Edge Milling Machine:

As can be observed from the above photo,

1) Length of the open type gantry beam structure mechanical body of the SXBJ-15 model machine of edge milling is 21m length: Which is, there is 15,000mm nominal stroke for milling on welding groove, plus 6,000mm length for accommodating width of the two milling carriages, in machine worktable of the SXBJ-15 model End Beveling Machine;

2) The machine body has up and down two sets of broad segments: Top pressing beam, and bottom work table of the machine for edge milling. The two segments are assembled into one integral body directly for acquiring better stiffness, and strengthened with two pieces of intermediate brackets at both ends of the End Chamfering Machine;

3) In view of horizontal way, the SXBJ-15 model machine of edge milling work table is assembled from 3 segments of 7m length each. The assembling process is strictly managed on its integral linearity, uniform, strength and firmness;

4) Each of the segments of the Edge Milling Machine work table is first welded in shape, then heat treated and finally precisely machined on Gantry Planar;

5) There are two sets of motorized milling carriages, assembled at the same side of machine of edge milling worktable. Installed with one set of 7.5kW milling head respectively. Higher power of milling head, such as 11kw is available for machining higher thickness of workpiece in the Edge Milling Machine;

6) Milling Head and its carriages installed in Wuxi JACK SXBJ-15 model large Sheet Metal Plate Beveling Machine: (Fig.5)

7) Steel Plate Loading: There is an array of floor fitting supporting racks of 1,200mm width for loading and unloading of workpiece (Sheet metal) into the machine of edge milling. The workpiece is put into machine of edge milling manually by hand;

8) The workpiece loading racks in Wuxi JACK Edge Milling Machine: (Fig.6)

9) Workpiece Clamp: There are 21 pieces of hydraulic drive jacks are fit at bottom surface of the SXBJ-15 model End Chamfering Machine pressing beam, for the purpose of holding and pressing workpiece tightly during work of the machine for fulfilling edge milling task. Quantity of these jacks varies among models of Plate End Beveling Machine depending on effective stroke of edge milling;

10) Hydraulic pump station is laid on the ground alongside the machine for edge milling, for giving power on the hydraulic jacks. Arrangement of its oil tubes are by way of the two row black color hard pipes on the machine of edge milling pressing beam (Shown in the attached 4th picture);

11) The electric control board for controlling the entire set of machine of edge milling is at terminal of work table. Besides, there is individual control cabinet for each set of the milling carriage, which is integrated inside column of the Edge Grooving Machine milling carriage. And, each of the milling unit has its dedicated operating panel.

C. Technical Parameters of SXBJ-15 Open Structure Edge Milling Machine:

Model Technical Parameter | Open Structure SXBJ-15 Double Heads Sheet Metal Plate Edge Milling Machine |

Max. Plate Edge Milling Length | 15,000 mm |

Power and rpm of Milling Head | 7.5 kW, 1440 rpm (Higher Power available) |

Spindle rpm of Edge Milling Head | 75 ~ 420 r/min., 6 grades by handwheel |

Hydraulic Power Motor | 5.5 kW |

Taper Hole of Milling Spindle End | ISO 50(7:24) |

Spindle Stroke | 100 mm |

Milling Head Quantity | 2 sets |

Plate thickness for Sheet Metal chamfering | 6∼80 mm (Under customer demand) |

Milling Angle of Top Milling unit | 0° to +80° |

Milling Angle of Down Milling unit | -45° to 0° |

Edge Milling Speed | 150∼1000 mm/min. Stepless |

High Speed of Idle | 4000 mm/min. |

Applicable Diameter of Facer Plate | D=Ø125 ~ Ø320mm (Ø200mm when making delivery) |

Quantity of Hydraulic Jacks | 21 pieces |

Quantity of Hydraulic Jack Screw | 4 sets, intermittently installed |

Worktable Width | 550 mm |

Worktable Height | 1050 mm |