A. The Advantage and Uniqueness of XBJ-9 Special Made Steel Plate Edge Milling Machine:

1. Featured Function: The XBJ-9 Single Head Special Made Steel Plate Beveling Machine of this product section, has the capability on getting additional 3000 mm to 4000 mm active stroke of steel plate edge milling, based on the nominal specification of 9000 mm stroke;

2. Which means 12,000mm increased to 13,000mm actual stroke in this special machine of edge milling ;

3. This is the reason that, why we name it XBJ-9 “Exceeding Nominal Stroke” special made machine for steel plate edge chamfering .

B. Comparison between XBJ-9 Conventional Standard and XBJ-9 Special Made Steel Plate Edge Beveling Machine:

1. There are Two Similar Models of Steel Plate End Milling Machine:

1) Standard conventional XBJ-9 single head configured machine of edge milling we introduced in the previous product section. This model accounts for majority, or to be specific, takes over 90% of actual business cases, in the product family of XBJ and SXBJ series Steel Plate Edge Milling Machine;

2) And XBJ-9 single head special made machine of steel plate end milling in this product section;

3) Please compare the photos of two types of Edge Milling Machine as below:

a) The Wuxi JACK standard conventional XBJ-9 single head configuration machine of steel plate edge milling: (Fig.1)

b) The Wuxi JACK XBJ-9 single head special made machine of steel plate edge beveling: (Fig.2)

2. Mechanical Structure Difference of the Two Types of Plate Edge Milling Machine:

1) As can be observed from the attached, above and below photos, the major difference between standard and this special made Edge Milling Machine here lies in general structure of the machine mechanical main body;

2) The standard conventional model machine of steel plate edge milling has open type gantry beam structure;

3) While the special made exceeding nominal stroke machine for plate end milling here has half enclosed frame type mechanical main body;

4) Another angle view on Wuxi JACK conventional standard open structure gantry beam Steel Plate Beveling Machine: (Fig.3)

3. Analysis on Major Structure Trait of XBJ-9 Special Made Steel Plate Edge Chamfering Machine:

1) General View: Major mechanical structure of XBJ-9 special made machine for steel plate edge milling: (Fig.4)

2) Wall Boards: As can be observed from the above photo, in this special made machine for end milling , there are 2 pieces of wall boards, which are marked in yellow color frame in the above photo, in size of (350mm thickness and 1000 mm extension) respectively, assembled at both sides of the XBJ-9 special made machine of edge milling mechanical main body;

3) Orifice: Besides, there are two orifices of (150mm height x 250mm depth) cut at the junction, between each piece of the wall board and working table of the special made plate Edge Beveling Machine main body. Please check below photo:

4) The orifice cut in both sides of special made machine for steel plate edge milling: (Fig.5)

5) Extending beyond End Milling Machine Working Table: In this way, during working of the XBJ-9 special made machine of steel plate edge beveling, the workpiece steel plate can be extended beyond reach of the entire working table in the machine of end milling;

6) Additional Stroke Available: And, by means of steel plate being manipulated horizontally in the special made machine of edge milling, the workpiece get additional stroke on edge milling welding groove;

7) More Rigid Edge Beveling Machine Main Frame: These two pieces of extended wall boards can also make the entire set of special made machine of steel plate end milling more steady in terms of standing;

8) The only downside with such structure of special made machine of steel plate edge beveling is, it has around 5% higher manufacturing cost up, compared with that of the routine standard type XBJ and SXBJ series Steel Plate Edge Milling Machine.

C. Usage and Application of XBJ-9 Single Head Special Made Steel Plate Edge Milling Machine:

1. Common Seen Grooving Make in the Steel Plate Edge Beveling Machine:

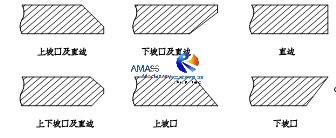

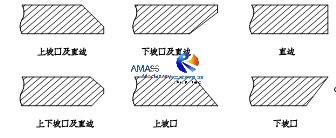

1) This single head general purpose XBJ and SXBJ models Steel Plate Edge Milling Machine is for the purpose of machining welding groove into required V/ K/ X types, on top edge/ Bottom edge/ Straight edge and slant edge of workpieces steel plate, such as:

2) The largest volume selected types of welding grooves machined from XBJ and SXBJ models machine of steel plate end milling: (Fig.6)

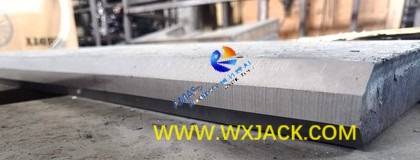

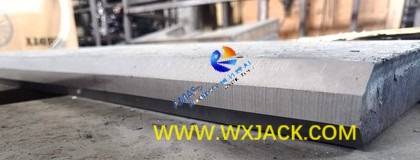

3) The finished edge milled steel plate delivered from Wuxi JACK Edge Milling Machine: (Fig.7)

2. Special Round Shape Grooving Making in the Special Made Steel Plate Beveling Machine:

1) Equipped with disc round shape milling cutter facer blade, this special made machine of steel plate edge milling can also perform sheet metal beveling of U shape chamfers;

2) For this reason, there are two sets of circular arc milling cutters, which are included in the supply range of this XBJ-9 special made machine for steel plate end milling;

3) The finished special round shape grooving chamfer, produced from Wuxi JACK Special Made Steel Plate Edge Chamfering Machine: (Fig.8)

D. Technical Parameters of XBJ-9 Single Head Special Made Steel Plate Edge Milling Machine:

Model Technical Parameter | Exceeding Nominal Stroke XBJ-9 Single Head Special Made Steel Plate End Milling Machine |

Max. Edge Milling Length on Metal Plate | Nominal Max. Stroke: 9,000 mm Actual Max. Stroke: 13,000 mm |

Max. Edge Milling Width on Metal Plate | 3,000 mm |

Metal Plate Thickness for Sheet Metal Edge Chamfering | 6∼50 mm (This is based on customer demand) |

Milling Angle Scope of Milling Head Unit | 0° to +60° |

Milling Head Quantity | 1 Set |

Quantity of Hydraulic Jacks for Pressing Steel Plates in Edge Milling Machine | 15 Pieces |

Power and rpm of Milling Head | 7.5 kW, 1440 rpm |

Spindle rpm of Edge Milling Head | 75 ~ 420 r/min., 6 grades by handwheel |

Hydraulic Power Motor | 5.5 kW |

Milling Unit Feeding Motor | 2.2 kW |

Edge Milling Speed | 130∼1000 mm/min. VFD, Inverter Control |

Idle High Running Speed of Milling Head Carriage | 4000 mm/min. Constant |

Applicable Diameter of Facer Plate | D=Ø125 mm ~ Ø320 mm (Ø200mm When making delivery) |

Hydraulic Rated Pressure | 5.5 MPa |

Hydraulic Working Pressure | 3.5 MPa |

Hydraulic System Flowrate | 47 L/min. |

Worktable Width | 1450 mm (Including Wall Board) |

Worktable Height | 1050 mm |