A. Technical Characteristics and Function of SXBJ-3 Automatic Sheet Metal Plate End Edge Milling Machine:

1. Technical Features of SXBJ-3 Automatic Sheet Metal Plate End Edge Beveling Machine:

1) Feature: SXBJ-3 is the smallest model of SXBJ series Double Heads Plate End Edge Milling Machine, in terms of edge milling stroke: Maximum 3000mm effective length;

2) The attached first, second and below photos show mechanical main body of Wuxi JACK SXBJ-3 model machine: (Fig.1)

3) Comparatively, the largest model in this product group is SXBJ-18 Automatic Sheet Metal Plate End Edge Milling Equipment;

2. Function of SXBJ-3 Automatic Sheet Metal Plate End Edge Beveling Machine:

1) SXBJ-3 is a kind of compact size but with multi-functional capability machine for edge milling:

2) Milling Heads: Equipped with 2 sets of milling head with different assembling orientation, both top and straight edges, as well as bottom edge bevels can be made in this plate End Edge Milling Equipment. Shown in below photo:

3) The 2 sets of milling head carriages assembled in different positions, in Wuxi JACK SXBJ-3 Plate End Edge Milling Machine: (Fig.2)

3. Application of SXBJ-3 Automatic Sheet Metal Plate End Edge Milling Equipment:

1) Usage: With max. valid plate edge chamfering stroke of 3000 mm, this SXBJ-3 double heads model machine for edge milling is basically used for milling out welding groove on upper and lower edges chamfers simultaneously, implemented on small and medium size workpiece steel plates in high efficiency, which is a niche product End Edge Beveling Machine for meeting specific demand on specific workpieces;

2) Wuxi JACK SXBJ-3 End Edge Chamfering Machine is working on bottom chamfers on a piece of small workpiece steel plate: (Fig.3)

3) Advantage: The SXBJ-3 is very handy and convenient for operation: With a set of operating pendant hang on the control board and moved along with milling carriage during work, the parameter setting up before operation, together with monitor in the process of plate edge beveling, are all within reach of arm’s length for operators;

4) Operation on Wuxi JACK SXBJ-3 Compact Size End Edge Milling Machine: (Fig.4)

4. Put into Use of SXBJ-3 Automatic Sheet Metal Plate End Edge Chamfering Machine:

1) Same as the remaining models of XBJ and SXBJ series Automatic Sheet Metal Plate End Edge Milling Machine, this SXBJ-3 model can be used for welding groove milling on upper and lower edges chamfers, completed in one time stroke of milling head carriage movement, which is accomplished by means of coordination of the two pieces of edge milling heads:

2) The 6 classical types of X/ Y/ K /V grooving available to be made from SXBJ models Double Heads Plate End Edge Milling Machine: (Fig.5)

B. Key Points and Productivity Analysis on Operation of End Edge Milling Machine:

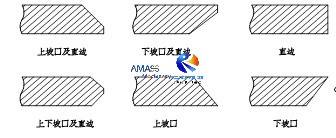

1. Classification on Chamfered Grooves Produced from End Edge Chamfering Machine:

For finished products from the automatic machine for sheet metal plate end edge beveling, all the chamfers and bevels can be grouped into three broad categories of:

1) Top or upper edges chamfers and bevels, that can be produced from the machine: (Fig.6)

2) Bottom or lower edges chamfers and beveling, that can be produced from double heads configuration machine for end edge milling: (Fig.7)

3) Straight or slant edges beveling and grooves, that are milled from the machine: (Fig.8)

2. Installation of Milling Heads in Double Heads Plate End Edge Milling Machine:

1) Assembling orientation of milling heads on the machine determines it can pick up only one type of the categories:

a) Either for milling on top edge chamfers and bevels, together with straight and slant edges;

b) Or for milling on bottom edges chamfers and bevels;

2) With one time stroke of plate edge beveling in the machine, the former type of milling head can only fulfil one type of chamfer: top edge chamfer, or straight edge groove on workpieces;

3) Suppose both types of grooving are necessary, the milling head needs to have back and

forth two times running stroke along worktable of the machine;

3. Completing on Complicated Jobs in Plate End Edge Milling Machine:

with top, bottom and straight edges grooves on edges of workpiece:

1) Material Handling: In SXBJ series double heads machine, the major steps cover one time of loading and unloading of workpiece steel plate, and two times running of the two sets of milling head carriage;

2) Material Flipping: As in the case of single head model equipment, the major step cover two times of loading and unloading, flipping the workpiece 180°, and three times running of the milling unit in the machine worktable;

3) This shows the productivity difference between double head SXBJ models and single head XBJ models Sheet Metal Plate End Edge Milling Machine.

C. Technical Parameters of SXBJ-3 Automatic Sheet Metal Plate End Edge Milling Machine:

Model Technical Parameter | Multi-Functional Up and Down Grooving SXBJ-3 Double Heads Automatic Sheet Metal Plate End Edge Beveling Machine |

Sheet Metal Plate Max. Edge Milling Length | 3,000 mm |

Sheet Metal Plate Max. Edge Milling Width | 3,000 mm |

Sheet Metal Plate Thickness Range for Sheet Metal Edge Chamfering | 6∼40 mm (This is based on customer demand) |

Quantity of Hydraulic Cylinder Drive Jacks | 8 Pieces |

Milling Angle Scope of Up Edge Milling Unit | 0° to +80° |

Milling Angle Scope of Lower Edge Milling Unit | -45° to 0° |

Power and rpm of Milling Head | 7.5 kW, 1440 rpm (Higher Power available) |

Spindle rpm of Edge Milling Head | 75 ~ 420 r/min., 6 grades by handwheel |

Hydraulic Power Motor | 5.5 kW |

Spindle Stroke | 100 mm |

Milling Head Quantity | 2 sets |

Edge Milling Working Speed | 150∼1000 mm/min. Stepless controlled with inverter |

Idle High Running Speed of Milling Carriage | 4000 mm/min. |

Applicable Diameter of Facer Plate | D=Ø125 ~ Ø320mm (Ø200mm when making delivery) |

Worktable Width | 450 mm |

Worktable Height | 1050 mm |