A. The Characteristic and Usage of 7 Axis 2000/6 High Precision Flame and Plasma CNC Pipe Intersection Cutting Machine:

1. As shown in the attached photos, this model of 7 Axis 2000/6 CNC Pipe Cutting Machine has relatively big height and short length, which is used for high precision cutting and slant chamfering on pipes, tanks, etc.:

1) The Max. size of workpieces available for cutting is Diameter Φ2000mm, length 6000mm, thickness up to 100mm for flame cutting;

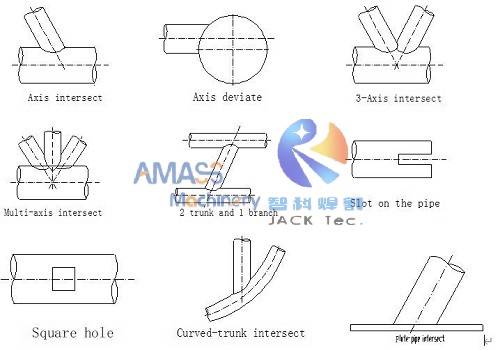

2) The classical cutting kerfs and swiveling grooves that can be cut from 7 Axis 2000/6 High Precision CNC Pipe Intersection Cut Equipment: (Fig.1)

3) Both flame cutting and plasma cutting available. Considering the large diameter of pipe, flame cutting is more applicable for 2000/6 specification of CNC Pipe Intersection Cutting Machine;

2. In a nutshell, same as 7 Axis 2500 series CNC Pipe Cutting Machine, here the 7 Axis 2000mm group Plasma Oxy-fuel High Precision CNC Pipe Cutting Machine, is the make up to the pipe diameter gap between Φ1400mm and Φ3000mm, enriching the product specifications of CP series Flame and Plasma CNC Pipe Intersection Cutting Machine.

B. The 7 Axis in 2000/6 High Precision Flame and Plasma CNC Pipe Cutting Machine:

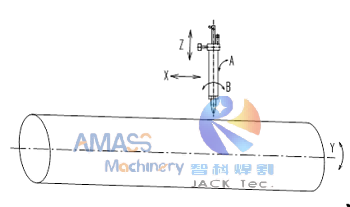

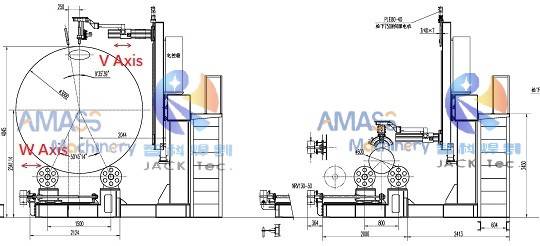

Due to the spatial distribution of 7 Axis, it is impossible to illustrate all the 7 axis in one sketch. So, we use 2 sketches to present these 7 Axis in CNC Pipe Cutting Machine:

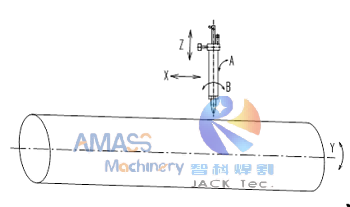

1. The X/Y/Z/A/B axis in 7 Axis High Precision Flame and Plasma CNC Pipe Intersection Cut Equipment:(Fig.2)

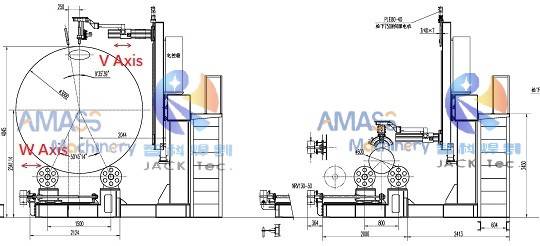

2. The V/W axis in 7 Axis High Precision CNC Pipe Intersection Cutting Machine: (Fig.3)

The W axis movement is for friction supporting rollers holding and revolving workpiece during work. It works in the same principle as Welding Rotator.

C. The High Precision Design in Wuxi JACK Flame and Plasma CNC Pipe Intersection Cutting Machine:

1. In the application field of CNC Pipe Cutting Machine, 7 Axis is synonym of “high precision”, which mean all around high standard control on this CNC Pipe Intersection Cut Equipment. Of which, the fitting and manipulating unit of cutting torch is of vital importance, and is apt to be ignored. However, it is the “final” and direct mechanism, for guaranteeing high precision of pipe cutting and beveling process, in CNC Pipe Cutting Machine;

2. For this Wuxi JACK has unique design on cutting torch manipulating cell, which is superior to that of other suppliers. Please check below photo and attached ones:

The cutting torch manipulating and swiveling element in Wuxi JACK CNC Pipe Intersection Cutting Machine: (Fig.4)

3. As can be seen from the above photo, the cutting torch unit of Oxy-fuel CNC Pipe Intersection Cut Equipment made by Wuxi JACK adopts gear and or bevel gear at all the revolving joints of the cutting torch unit, not a shaft at that of the competitors. Such kind of design in CNC Pipe Cutting Machine makes motioning and positioning of the cutting torch boosting the highest degree of accuracy. It is just one of the examples showing how do Wuxi JACK pay every attention on every detail of all our products.

D. Technical Parameters of Wuxi JACK 7 Axis 2000/6 High Precision CNC Pipe Cutting Machine:

Below is specification of 7 Axis 2000/6 Flame and Plasma High Precision CNC Pipe Intersection Cut Equipment:

Model Technical Parameter | 7 Axis 2000/6 High Precision Flame and Plasma CNC Pipe Intersection Cutting Machine |

Valid Diameter Range of Pipe | 400 ~ 2000 (mm) |

Valid Max. Length of Pipe (mm) | 6000 |

Valid Thickness Range of Pipe (mm) | 6~100 mm for flame cutting; 3 ~ 25mm for plasma cutting |

Valid Cutting Speed | 200∼800mm/min. for flame cutting Around 200~ 2000mm/min. for plasma cutting (Based on thickness of Pipe and Plasma Power) |

Active CNC Control Axis | 7 Axis of X/Y/Z/A/B/V/W X Axis: For cutting torch movement along pipe longitudinal; Y Axis: For managing workpiece revolving; Z Axis: For lifting and lowering down cutting torch; A Axis: For tilting cutting torch along workpiece radius; B Axis: For tilting cutting torch along pipe longitudinal; V Axis: For moving cutting torch along workpiece radius; W Axis: For moving pipe supporting rollers along transverse |