Background of HB1500 I H Beam Production Line:

1) The attached first photo was taken at submerged arc welding station of HB1500 automatic line for H Beam production produced by Wuxi JACK;

2) As you can find from the photo, there is a piece of welded H Beam being welded at the 45° Steel Structure Flipping Equipment, of the LHC model H Beam Gantry Welding Machine.

1. The Application of HB1500 Automatic Welding H Beam Production Line:

1) Function: The HB1500 line with SAW (Submerged Arc Welding Machine) is a streamline of fully automatic H Beam Production Machine, for high efficient and quality producing welded H Beam of medium size: The biggest web height is 1500mm. Detailed specification of the delivered H Beam please check parameters at the end of this model product section:

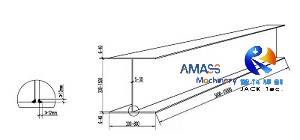

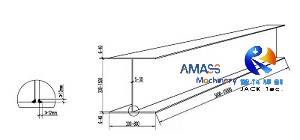

Cross section of finished welded fabricated H Beam for line of automatic production: (Fig.1)

2) Synonym: Depending on the local habitual name of different countries and regions, H Beam has the other name of I Beam; Corresponding, this automatic line has the synonym of I Beam Production Line.

2. The Finished Workpiece Produced from HB1500 Automatic Welding H Beam Production Line:

1) Important Workpiece: In Steel Structure Industry, H Beam/ I Beam is the most popular used raw material in construction of various projects, ranging in broad size;

2) Major 2 Types of H Beam: Based on its manufacturing process and finished size/ mechanical property, H Beam falls into two broad categories of: Hot rolled and welded type. The hot rolled H Beam usually has smaller size, while welded H Beam usually has larger size:

General sizes of welded H Beam to be produced from production line: (Fig.2)

3) The Welded H Beam produced has sizes of:

a) The largest web height of 1500mm;

b) 200 ~ 800mm H Beam flange width;

c) Flange and web thickness from 5mm to 32mm / 40mm respectively;

d) In the length of 4,000mm ~ 12,000mm.

3. Process Technology in HB Series Automatic Welding H Beam Production Line:

The entire H Beam production process of this automatic line mainly includes major steps of:

1) Plate Strip Cut station:

a) This station is for the purpose of cutting carbon steel plate into long narrow strip boards, serving as flange and web for welded H Beam:

Strip plates as flanges and web of H Beam: (Fig.3)

b) The related H Beam Production Machine is CNC-CG4000 CNC Strip Plate Cutting Machine;

2) Assembling and Tack Welding Step: H Beam Assembly Machine:

a) Task: This work station is for the purpose of assembling flanges and web into first T Beam and then H Beam, as well as spot CO2 welding at the same time, to solidify the structure of assembled H Beam:

Fitting up and simultaneously having stitch welding on H Beam: (Fig.4)

b) The related machine adopted is Z15 H Beam Assembly Machine. Please check the second photo;

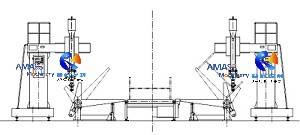

3) The SAW Welding Station: H Beam Gantry Welding Machine

a) Function: This work station is for the purpose of implementing on 45° fillet submerged arc welding on the half finished fabricated H Beam, delivered from the previous step of H Beam Assembly Machine:

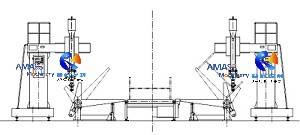

2 sets of LHC model H Beam Gantry Welding Machine work in symmetry in the line: (Fig.5)

b) The related H Beam Production Machine adopted is LHC model H Beam Gantry Welding Machine. Please check the third photo;

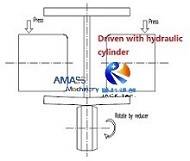

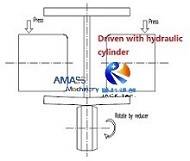

4) H Beam Flange Straightening: H Beam Straightening Machine

a) Role: This work station is for straightening deformed flange post submerged arc welding, of the previous station of H Beam Gantry Welding Machine:

Flattening out H Beam flange deformation: (Fig.6)

b) The related H Beam Production Machine adopted is HYJ-40 or HYJ-800 model. Please check the fourth photo.

4. Technical Features of Automatic Welding H Beam Production Line:

1) Core Equipment: Whatever it is Automatic or Semi automatic working mode, the above mentioned four sets of machine equipment are indispensable for all process technology of welded H Beam;

2) The difference between Automatic and Semi Automatic line lies in whether applying Steel Structure Flipping Equipment for moving workpieces among work stations. Please check the fifth photo:

Steel Structure Flipping Equipment applied in Automatic Welding H Beam Production Line: (Fig.7)

3) Fully Automation: For automatic line, with the deployment of Steel Structure Flipping Equipment, including overturning units and conveyors, least operators are involved for production of welded H Beam, and the entire line of automatic H Beam Production Machine features in high automation and smooth running.

5. Technical Parameters of HB1500 Automatic H Beam Production Line:

Model | HB1500 Automatic Welding H Beam Production Line |

Max. H Beam Web Width | 1500 mm |

H Beam Web Thickness | 6∽32 mm |

H Beam Flange Width | 200∽800 mm |

H Beam Flange Thickness | 6∽40 mm |

H Beam Length | 4000∽12000 mm |

Max. H Beam Weight | 20 Ton. |

H Beam Production Machine for Assembly | Z15 model H Beam Assembly Machine with Tack Welding, CO2 Spot Welding |

Machine for SAW Welding | LHC model H Beam Gantry Welding Machine |

Machine for Flange Straightening | HYJ-40 or HYJ-800 H Beam Straightening Machine |

Machine for Transfer of H Beam workpiece among stations | Steel Structure Flipping Equipment: Flipping units/ Conveyor/ Travel Cart |