A. Come into Being of Multi Axis: From 3 Axis, to 5 Axis CNC Pipe Cutting Machine, to 6 Axis CNC Pipe Cutting Machine, to 7 Axis CNC Pipe Cutting Machine:

1. 3 Axis Control for Basic Function in CNC Pipe Cutting Machine:

Multi Axis is defined compared with the basic configuration of 3 Axis CNC Pipe Cutting Machine, which completes the task of:

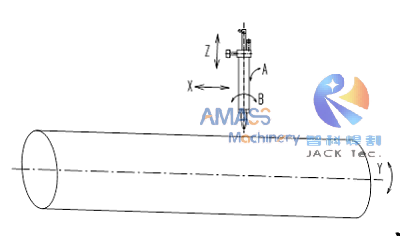

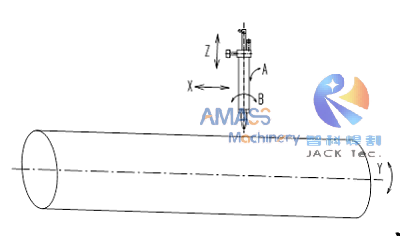

1) X axis: Pipe cutting along direction of pipe length;

2) Z axis: Cutting torch lift up and lower down along pipe diameter;

3) Y axis: Pipe revolving around its periphery;

2. Expand to 5 Axis CNC Pipe Intersection Cutting Machine for Oblique Chamfer:

1) To fulfil more advanced function of slant full circle beveling, Multi axis is introduced to CNC-CP series CNC Pipe Intersection Cutting Machine;

2) This upgrade starts from 5 Axis CNC Pipe Intersection Cutting Machine,

Which have:

a) The 4th A axis: For managing cutting torch ±45° tilting along pipe radial direction;

b) The 5th B axis: For managing cutting torch ±45° tilting along pipe axial direction:

2) The X/ Y/ Z/ A/ B axis in 5 Axis CNC Pipe Cutting Machine: (Fig.1)

3) Elliptical cutting kerf produced from Wuxi JACK 5 axis CNC Pipe Cutting Machine: (Fig.2)

3. Extended to 6 Axis CNC Pipe Intersection Cutting Machine for Cutting Large Pipes:

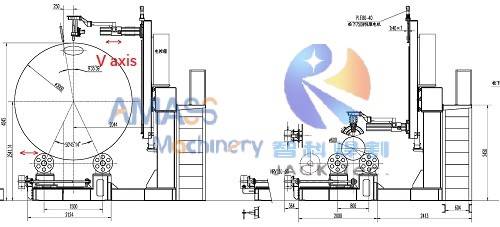

1) Infinite revolving beveling can be realized with 5 Axis CNC control in small to medium large diameter pipes: Φ600mm~Φ1400mm;

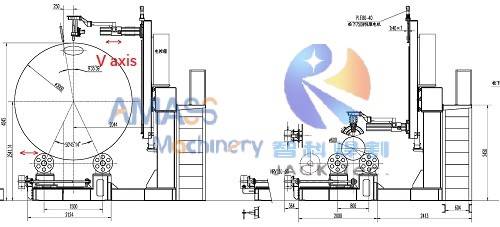

2) Large CNC Pipe Cutting Machine: When pipe diameter exceeds Φ1400mm, and reaches the range of Φ2000mm to Φ2500mm, the solitary pipe revolving B axis can not manage pipe cutting and beveling satisfactorily in terms of both quality and quantity, and by this time V axis for cutting torch adjustment in radius way is used: This comes into being 6 Axis CNC Pipe Cutting Machine:

3) The V axis in 6 Axis CNC Pipe Intersection Cutting Machine: (Fig.3)

4. Being Extended to 7 Axis CNC Pipe Intersection Cutting Machine for Cutting Super Large Pipes:

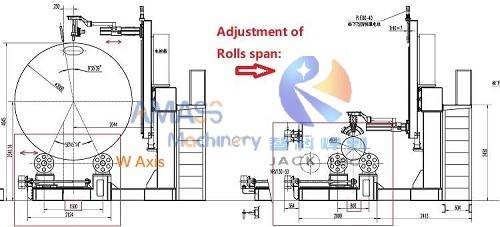

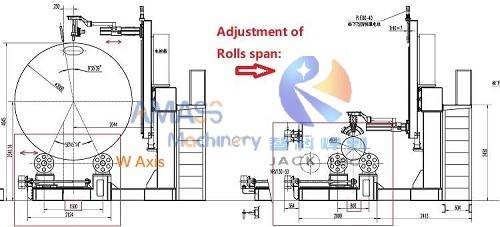

1) Threshold: When diameters of pipe grow larger than Φ2500mm and reaches Φ3000mm, the 6th V axis is not enough for adjusting cutting point in transverse way of the Large CNC Pipe Cutting Machine;

2) The 7th axis W axis: By this time, the 7th axis W axis needs to be introduced to CNC Pipe Cutting Machine, which controls lateral movement of friction rollers for supporting large pipes. By changing the span of the 2 sets of friction rollers, larger pipes can be accommodated, and cutting torch can be controlled conveniently in this Large CNC Pipe Intersection Cutting Machine:

3) The W axis in 7 Axis CNC Pipe Intersection Cutting Machine: (Fig.4)

B. Cutting Torch Analysis in 7 Axis/ 6 Axis/ 5 Axis CNC Pipe Cutting Machine:

1. One cycle of cutting torch action during running of the 7 /6 / 5 Axis CNC Pipe Cutting Machine is indicated in below 9 frames of animation pictures: (Fig.5)

1) B Axis: Cutting torch swings leftward along pipe axial direction;

2) A Axis: Cutting torch swings forward slightly along pipe radial direction;

3) A Axis, B Axis: Cutting torch swings forward still further and rightward along pipe radial direction of the 5 Axis CNC Pipe Cutting Machine;

4) A Axis, B Axis: Cutting torch swings backward and rightward slightly along pipe radial direction;

5) A Axis, B Axis: Cutting torch swings backward and leftward still further along pipe radial direction of the 5 Axis CNC Pipe Cutting Machine;

6) A Axis, B Axis: Cutting torch swings backward and leftward along pipe axial and radial direction;

7) A Axis, B Axis: Cutting torch swings backward and rightward along pipe axial and radial direction;

8) A Axis, B Axis: Cutting torch swings forward and leftward along pipe axial and radial direction;

9) A Axis, B Axis: Cutting torch swings forward and rightward along pipe axial and radial direction of the 5 Axis CNC Pipe Intersection Cutting Machine;

2. As complement, the V axis and W axis for operation of 6 Axis CNC Pipe Cutting Machine and 7 Axis CNC Pipe Cutting Machine:

1) Meanwhile, pipe rotates (Y Axis);

2) To have precise positioning, the cutting torch moves forward and backward along pipe radial way (V Axis), leftward and rightward along pipe radial way (X Axis), and moves up and down to cater for changing height of pipe surface (Z Axis), in 7 Axis/ 6 Axis CNC Pipe Intersection Cutting Machine;

3) And, catering for different diameter of workpiece, W Axis of turning rolls adjustment is manipulated when loading a new pipe onto the 7 Axis / 6 Axis CNC Pipe Cutting Machine;

4) From the above-mentioned example we can see how does the 7 Axis/ 6 Axis/ 5 Axis CNC Pipe Cutting Machine work.

C. Technical Parameters of 7 Axis/6 Axis/ 5 Axis CNC Pipe Cutting Machine:

Model Technical Parameter | 7 /6 / 5 Axis CNC Pipe Intersection Cutting Machine |

Max. Diameter of Workpiece Pipe | 1400 ~ 3000 (mm). Minimum diameter depends on specific applicating cases |

Applicable Pipe Length Range | 1000 ~ 15,000 (mm) |

Applicable Pipe Thickness Range | 5~100 mm for flame cutting; 5~25mm for plasma cutting |

Applicable Cutting Speed | 100 ∼ 1000 mm/min. for flame cutting; 100 ∼ 3000 mm/min. for plasma cutting; Controlled with CNC |

Idle Speed of Cutting Torch | 4000 mm/min. |

Beveling Angle Range for Groove | ±45° |

Active CNC Control Axis | 5/6/7 Axis of X/Y/Z/A/B/V/W X Axis: For cutting torch adjustment along pipe length Y Axis: For pipe infinite 360° rotation; Z Axis: For cutting torch up and down; A Axis: For swiveling cutting torch along pipe radius; B Axis: For swiveling cutting torch along pipe axial; V Axis: Cutting torch along pipe radial; W Axis: For friction rollers moving along pipe radius |