1. The Distribution of HB Series Light duty Welding Positioner Welding Turntable:

1) Applicating Cases: The attached photos show several examples of Wuxi JACK Small Welding Positioner with light loading capacity. These small Welding Turntable is the lightest of its kind in practical use;

2) Standard loading capacity Welding Turntable in this sub group is 100kg, 300kg, and 600kg. Correspondingly, the models of these tonnage are HB1, HB3, HB6 respectively;

3) Special Design: Besides, there are also other special made specifications of the Small Rotary Welding Table that can be chosen from. For example, below illustration picture of item 5) shows a 200kg loading tonnage HB2 model Single Work Table Welding Positioner.

2. Application and Using Tips of HB Series Light duty Portable Welding Positioner Rotary Welding Table:

1) Usage of Small Welding Positioner Welding Turntable:

a) These light duty HB series welding positioner is usually used for fabricating on small sizes of workpieces: Pipes, tubes, flanges, etc.;

b) Another often seen application of small Light Duty products is for laboratory use;

2) Using Tips on Operating Light Duty Welding Positioner:

a) Suggestion on put onto Worktable: Same as light duty Welding Rotator, because of its small height of Welding Turntable which is much shorter than an adult operator, to help operator operating the Small Welding Positioner comfortably during welding period, many times these portable welding equipment is located on a set of work table, so that operator can manage on working process conveniently;

b) Secured tightly into Mounting Surface: Light duty Welding Positioner has small and relative lightweight of mechanical body Welding Turntable, which is difficult to hold itself steadily, especially during welding stage on the Rotary Welding Table. For this reason, to have Welding Turntable body standing firmly during operating period, its Rotary Welding Table should be secured into workshop floor by means of the 4 pieces of foot plates and bolts.

3. Technical Features of HB Series Small Welding Positioner Welding Turntable:

1) Durable Mechanical Body:

With such small size of the Rotary Welding Table and its mounting base, mechanical main frame is as strong and solid as the remaining larger tonnage of the medium duty and heavy duty Welding Positioner;

2) Fixing Unit in Small Welding Positioner Welding Turntable:

a) Supplementary Unit: Due to its small size of Rotary Welding Table, sometimes an assistant unit is necessary to help clamping workpiece of longer length;

b) For example, below picture shows a set of 200kg loading capacity Welding Positioner: We can see there is a piece of 3 claw chuck on the top surface of the Rotary Welding Table for fixing the workpiece; Meanwhile, a split type supporting rack with 2 pieces of red color rollers is used to serve as holding unit of the workpiece into this Portable Welding Positioner. In this respect, the fixing unit plays the similar rule as Welding Fixture;

Fixing Unit in small Welding Positioner: (Fig.1)

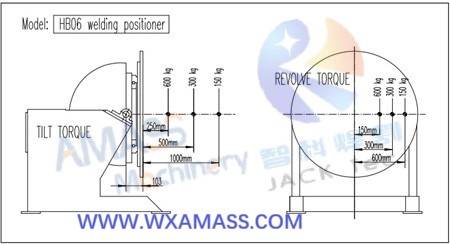

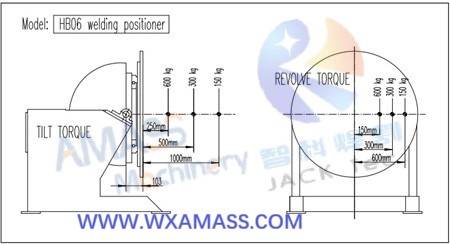

3) Torque Design in the Portable Welding Positioner Welding Turntable:

a) Torque design on revolving torque and tilting torque of the Rotary Welding Table is the most important technical topic, for any set of Welding Positioner;

b) As an example, torque design for the Rotary Welding Table of 600kg loading tonnage please check below design sketch: (Fig.2)

4. Operation in HB Series Light duty Welding Positioner Rotary Welding Table:

1) Operating panel of the light duty Rotary Welding Table is integrated into top cover of the control board, and put alongside the portable welding positioner: (Fig.3)

2) Welding Speed: Same as other types of Welding Positioner, revolve velocity of Rotary Welding Table, which is the welding speed on the workpiece, is adjustable with VFD (Variable frequency drive) controlled with A.C. inverter. For customers, they can control the revolve speed of the Rotary Welding Table with pendant.

5. Technical Parameters of HB Series Light duty Small Welding Positioner Welding Turntable:

Standard Models of HB Series Light duty Small Welding Positioner (Welding Turntable) |

Model | HB1 | HB3 | HB6 |

Loading Capacity (kg) | 100 | 300 | 600 |

Workpiece Revolve Speed (rpm) | 0.1-1 | 0.2-2 | 0.1-1.1 |

Workpiece Tilt speed (rpm) | 2 | ≈0.9 | ≈0.8 |

Rotary Welding Table Diameter (mm) | φ400 | φ600 | φ800 |

Max. Eccentricity (mm) | 100 | 150 | 150 |

Max. Gravity Center Distance (mm) | 150 | 200 | 250 |

Workpiece Tilt Range | 0°-120° |

Revolve Diameter at 900 mm | ≤600 | ≤1000 | ≤1500 |

Welding Speed Adjustment | Revolve speed is VFD. Tilt speed is constant (Ordinary brake motor) |