A. Applicable Workpiece and Usage of CHB30 Model Tilting and Rotary Welding Positioner:

1. Function of the CHB30 Model Revolving and Tilting Welding Positioner:

1) This Light Welding Positioner is designed for tilting and rotating workpieces products with diameter ranging from Φ600 mm to Φ1700 mm in position, which is suitable for acquiring optimum welding and or cutting effect;

2) The corresponding welding speed can be available, in the form of automatic, semi-automatic and manual arc welding, being implemented in the shop and installation conditions of the Tilting and Rotary Welding Positioner;

2. Workpiece Specifications of The CHB30 Model Light Welding Positioner:

1) Diameter of the workpiece shell flange cross section, is from Φ600 mm to Φ1700 mm;

2) Height of the workpiece shell flange can be up to 1500 mm;

3) Max. weight of the workpiece shell flange can be up to 2500 kg;

4) Loading Tonnage: Correspondingly, this Turning Table Positioner should have loading capacity of 3 Ton, with certain tolerance of margin. So, the model is CHB30;

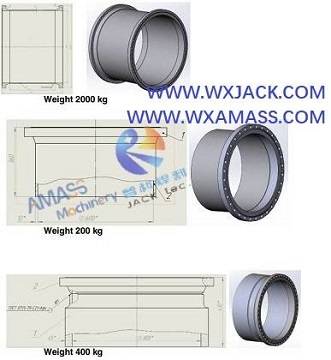

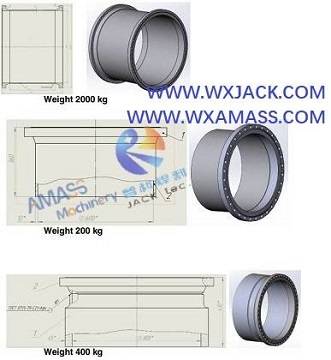

3. 3D design model of workpiece for the CHB30 Tilting and Rotary Welding Positioner: (Fig.1)

B. Demand from Customer on CHB30 Model Welding Turning Table Positioner:

1. Working Actions of the CHB30 Turning Table Welding Positioner:

1) Limitation: This 2 axis Welding Rotary Table should be able to rotate to max. degree of 360°, and tilt the workpiece and its fixture up to 135°;

2) The loading capacity of the Rotary Welding Positioner with a clamping chuck should be provide rotation; And rotation with an inclination of 45° degree and horizontal position of the workpieces weighing can be kept at min. 3000 kg;

3) Operating stage of the Wuxi JACK CHB30 Welding Rotary Table Welding Positioner at customer site: (Fig.2)

2. Working Velocity of Revolving and Tilting in the CHB30 Tilting and Rotary Welding Positioner:

1) Revolving: The rotation drive of the Welding Rotary Table should be able to provide smooth adjustment, on the rotational speed of the workpiece shell flange, ranging from 100 mm/min. to 2000 mm/min.;

2) Welding: Speed of rotation welding is from min. 100 mm/min. up to max. 1500 mm/min., which marches perfectly with the scope of: From min. 1000 mm/min., up to max 2000 mm/min.;

3) Speed Control: The workpiece welding speed should be adjustable, during rotation of the Welding Rotary Table;

4) Modulation and Displaying: Besides, this rotating and working speed of the workpiece in the Light Welding Positioner, should be able to be adjusted and displayed on operating pendant instantaneously;

5) Operating pendant of CHB30 model Tilting and Rotary Welding Positioner: (Fig.3)

6) Tilting Duration: Tilting speed of Welding Rotary Table and its workpiece to 90° degree, which takes around 40 to 60 seconds;

3. Structure and Size of CHB30 Model Welding Turning Table Positioner:

1) This small welding positioning equipment has compact and integral structure, with major structure of a set of stationary base Turning Table Welding Positioner;

2) The Welding Rotary Table at its top has capability of 2 degrees of freedom: 0° ~ 360° revolving and 0° ~ 360° tilting, for managing workpiece position and orientation;

3) Commissioning on CHB30 model at Wuxi JACK facility: (Fig.4)

4. Operating Modes in CHB30 Model Welding Turning Table Positioner:

1) The revolving and tilting speed indicator on the welding positioning equipment, should be on the stationary console, and on the remote operating handheld console in the form of mm/min.;

2) The workpiece shell flange platter tilting indicator of the Tilting and Rotary Welding Positioner, should be on the stationary console, and on the handheld console in degrees.

C. Technical Specialties of CHB30 Model Turning Table Welding Positioner:

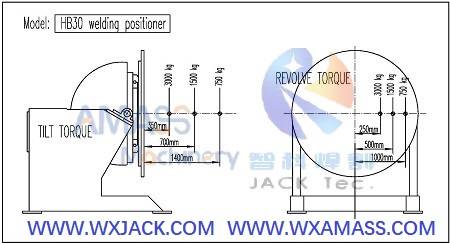

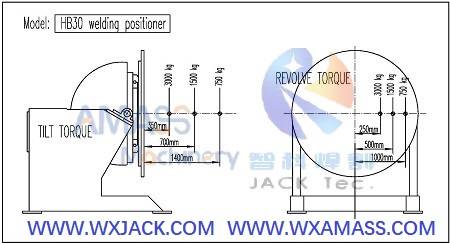

1. Revolve and Tilt Torque Indicating Diagram of Wuxi JACK CHB30 model Tilting and Rotary Welding Positioner: (Fig.5)

2. Configurations and Specifications in CHB30 Model Welding Turning Table Positioner:

1) This Rotary Welding Positioner is equipped with a piece of 6 beams steel plate, with a maximum diameter of Φ1700 mm, with holes cut in its surface, for the purpose of mounting a chuck or clamping devices, for the duty of fixing working parts securely onto its Welding Rotary Table;

2) The welding fixture includes a piece of mechanized 3- or 4-jaw clamping chuck, for the task of clamping working parts with diameters from Φ600 mm to Φ1700 mm;

3) The 4 jaws chuck fixture applied in Wuxi JACK CHB30: (Fig.6)

3. Constructure of CHB30 Model Welding Rotary Table Positioner:

1) The support structure of the Welding Turning Table Positioner should be stable, and does not require additional attachment to hold it;

2) Height from workshop floor level to axis: The rotation of the Welding Rotary Table and workpiece in the horizontal position of the product workpiece, should be maintained from 1200 mm to 1300 mm;

3) Installation and fixation of array of Wuxi JACK CHB30 model welding positioning equipment: (Fig.7)

4) Easily compatible with any welding source and mechanization, synchronized with welding by turning on the start button, with the start of welding on the remote and the foot pedal switch control;

5) The foot pedal switches equipped with Wuxi JACK Revolving and Tilting Welding Positioner: (Fig.8)

D. Range of Supply on CHB30 Model Welding Turning Table Positioner:

1. Mechanical main body of the fixed Welding Rotary Table itself;

2. Electric control board, operating pendant and foot pedal switch;

3. There are no consumable spare parts necessary for being equipped with the welding positioning equipment, because all the components and parts are durable type;

4. Operating Units in Turning Table Welding Positioner:

1) Remote control pedal: 1 piece with cable length of 5,000 mm;

2) Manual control (Or radio control) of 1 piece, with cable length in the length of 5,000 mm;

5. Functionality of Push Buttons on Remote Control of Welding Rotary Table:

1) It should be able to revolve in CW clockwise versus CCW counterclockwise rotation direction, selected by means of toggle switch;

2) Controlling buttons to start rotation of the Turning Table Positioner;

3) Adjustment on rotation speed of the Welding Rotary Table.

E. Technical Parameters of CHB30 Model Welding Rotary Table Positioner:

No. | Model | CHB30 Turning Table Welding Positioner |

1 | Max. Loading Capacity | 3,000 kg |

2 | Workpiece Revolve Linear Speed | 0.05-0.5 rpm (Diameter Φ600 is 95 ~ 1000mm/min. Diameter Φ1700 is 250 ~ 2500mm/min.) |

3 | Workpiece Tilt Speed | ≈0.4 rpm ( Tilt 90° need 37.5sec) |

4 | Welding Rotary Table Diameter | φ1500 mm |

5 | Max. Eccentricity of Revolve | 250 mm |

6 | Max. Gravity Center Distance of Tilt | 350 mm |

7 | Revolving Motor Power | 2.2 kW |

8 | Tilting Motor Power | 2.2 kW |

9 | Workpiece Tilt Range | 0°-135° |

10 | Revolve Diameter at 900 | ≤2300 mm |

11 | With 4 Jaws Clamp Chuck | One set, suit Diameter Φ600~ Φ1700mm |

12 | Revolve Speed Adjustment | Revolve speed is VFD. (Ordinary brake motor) 14

|

13 | Tilting Speed Adjustment | Tilting speed is constant (Ordinary brake motor) |

14 | Control Box | One set remote control panel |