1. The Definition and Characteristic of HB series Universal Welding Positioner:

1) This HB series Welding Positioner is a kind of universally applied Welding Positioning Equipment, for welding different structures and sizes of structure members, pipe flanges, and other specially designed workpieces across the industry;

2) Default Type: When talking about Weld Positioner, this species of product is the first one coming into people’s mind: It represents on the typical and standard design on this product group of Welding Turning Table. All the remaining upgraded models and special made Welding Positioning Equipment are all originated from this series of welding equipment.

2. Technical Features of HB Series Universal Rotary Welding Positioner:

1) Quantity of Welding Turning Table:

a) From the aspect of mechanical body structure, it can be classified as single Welding Turning Table Welding Positioner, because it has one piece of work table. Comparatively, there are Double Table Top Universal Variable Speed Electric type, which we will introduce in the later product section;

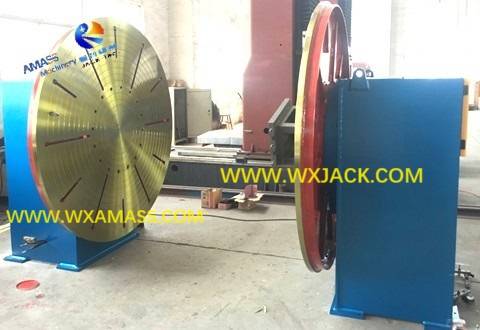

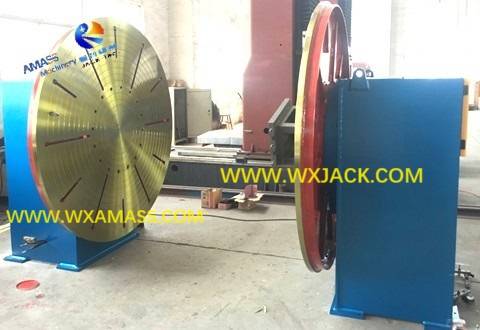

Welding Turning Table: (Fig.1)

b) The single worktable Rotary type is usually used for short and medium length of structure member workpieces;

2) Type of Welding Turning Table in the Welding Positioner:

The working table can be:

a) Either round shape: This is the most often used type in practical application. Please check attached photos;

b) Or square shape table: This is out of demand on catering for the outline of specific structure member;

Welding Turning Table fixed with workpiece: (Fig.2)

c) Or Branch type Welding Positioner: This is often adopted in Heavy duty Welding Positioner, so that deadweight of the Welding Turning Table itself can be reduced to the minimum level;

Special design Welding Turning Table in large loading tonnage Welding Positioner: (Fig.3)

d) Or any other special designed type Welding Turning Table, depending on specific workpiece characteristic used;

3) Assisting Mechanisms in the Weld Positioner:

a) To firmly fix the workpiece onto the Welding Turning Table, usually a piece of chuck with custom design is used. This chuck is designed and produced differing from one another, in actual application cases;

b) So, the product can also be called Welding Positioner with chuck;

4) Workpiece Height Adjustment in the Welding Positioner:

Considering Welding Turning Table movement along vertical direction of Z axis, this single table top Welding Positioning Equipment has Stationary type and Elevating type Welding Positioner;

5) Loading Capacity of Rotary Welding Positioner:

a) This series of universally applied welding machinery has broad range of loading capacity. The standard models of the Welding Positioning Equipment cover the range from 100kg to 50 Ton, which can meet on most majority application needs for customers. Please check below table for technical parameters of all standard models of the HB series single working table products;

b) Meanwhile, special loading capacity is also available;

6) Subdivision of Single Welding Turning Table Welding Positioner:

In terms of loading capacity, this single working table Welding Positioner can be divided into 3 groups of:

a) Light duty models (Less than 1 Ton), the next product section;

b) Medium duty models (1 Ton~ Less than 10Ton);

c) Heavy duty models (10 Ton and above)

We will introduce the above mentioned 3 groups of products individually in the next following sections.

3. Technical Parameters of HB series Single Welding Turning Table Welding Positioner:

HB Series Single Welding Turning Table Industrial Universal Rotary Welding Positioner with Chuck |

Model | HB1 | HB3 | HB6 | HB12 | HB20 | HB30 | HB50 | HB80 | HB100 | HB150 | HB200 | HB300 | HB500 |

Loading (kg) | 100 | 300 | 600 | 1200 | 2000 | 3000 | 5000 | 8000 | 10000 | 15000 | 20000 | 30000 | 50000 |

Revolve speed (rpm) | 0.1-1 | 0.2-2 | 0.1-1.1 | 0.1-1 | 0.1-1 | 0.08-0.8 | 0.07-0.7 | 0.06-0.6 | 0.06-0.6 | 0.05-0.5 | 0.05-0.5 | 0.04-0.4 | 0.04-0.4 |

Tilt speed (rpm) | 2 | ≈0.9 | ≈0.8 | ≈0.5 | ≈0.4 | ≈0.3 | ≈0.2 | ≈0.14 | ≈0.14 | ≈0.14 | ≈0.14 | ≈0.10 | ≈0.10 |

Welding Turning Table Diameter (mm) | φ400 | φ600 | φ800 | φ1000 | φ1200 | φ1400 | φ1600 | φ2000 | φ2000 | φ2200 | φ2500 | φ3000 | φ4000 |

Max. Eccentricity (mm) | 100 | 150 | 150 | 200 | 250 | 250 | 250 | 200 | 200 | 200 | 200 | 200 | 200 |

Max. Gravity Center Distance (mm) | 150 | 200 | 250 | 250 | 300 | 400 | 400 | 400 | 400 | 500 | 630 | 630 | 800 |

Welding Turning Table Tilt Range | 0°-120° |

Revolve Dia. at 900 mm | ≤600 | ≤1000 | ≤1500 | ≤1500 | ≤2000 | ≤2300 | ≤2800 | ≤3200 | ≤3200 | ≤3400 | ≤3400 | ≤4200 | ≤5700 |

Speed Adjustment | Revolve speed is VFD. Tilt speed is constant (Ordinary brake motor) 14

|