1. Usage of HJ-300 Lengthwise H Beam Straightening Machine:

1) HJ-300 is the largest model of its kind for straightening on: H Beam/ BOX Beam/ steel structural members and other types of Section Steel along workpiece length direction:

Typical workpieces for H Beam Straightening Horizontal Press: (Fig.1)

2) With the biggest output tonnage of 300 ton, the expected largest thickness of H Beam flange available for being straightened in HJ300 model can be about 40 mm.

2. Empirical Data on Relationship between Tonnage and Workpiece Size in HJ Series H Beam Straightening Horizontal Press:

As introduced in the previous section of “HJ series Lengthwise I Beam Straightening Machine”, there is rule of thumb accumulated by Wuxi JACK engineering team, based on the original development data and years of experience of the HJ series straightening equipment:

Model | Max. Tonnage of Press (Ton) | Max. H Beam Size that can be Straightened (mm) In HJ series Lengthwise H Beam Straightening Machine |

Web Height | Web Thickness | Flange Width | Flange Thickness |

HJ20 | 20 | 400 | 10 | 200 | 12 |

HJ100 | 100 | 500 | 12 | 400 | 20 |

HJ200 | 200 | 600 | 30 | 500 | 35 |

HJ300 | 300 | 800 | 32 | 600 | 40 |

2) Fitting Application of HJ Series Structural Member H Beam Straightening Horizontal Press:

From the above list of specification we can have impression:

a) HJ300 and HJ200 models are for straightening on middle size thickness workpiece;

b) HJ100 and HJ20 models are for straightening on small size thickness workpiece;

c) For larger size steel structure workpieces, usually deformation along its longitudinal direction is not so obvious to be necessary for straightening;

d) Besides H Beam, the H Beam Straightening Horizontal Press can also be used for straighten on other types of section steels and structural members.

3. Specifications of HJ300 Lengthwise H Beam Straightening Machine:

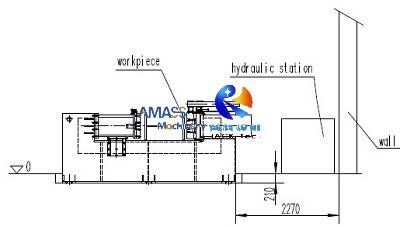

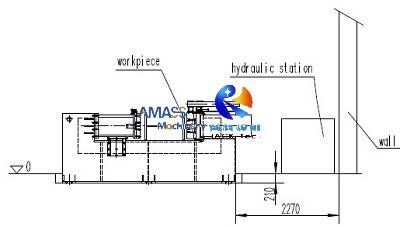

Below are main specifications and technical parameters of HJ300 model: (Fig.2)

1) Conveyor motor power of the HJ300 is 1.5 kW *2;

2) Hydraulic Driving Cylinder of HJ300 Lengthwise H Beam Straightening Machine:

a) Cylinder diameter is 400mm;

b) Rod diameter is 320mm;

c) Stroke of the oil cylinder is 800mm;

3) Hydraulic System of HJ300 Lengthwise H Beam Straightening Machine:

a) Driving motor of the hydraulic system is 22 kW;

b) Rated work pressure of the hydraulic system is 25 MPa;

c) Max. system pressure of the hydraulic system is 32 MPa;

4) Differentiating Factor among Models of HJ Series H Beam Straightening Horizontal Press Machine: (Fig.3)

Among the above technical data, the variable parameter is power of hydraulic driving motor. For the other models of the HJ series, hydraulic driving motor of each HJ model is listed as below:

a) HJ200: 11 kW;

b) HJ100: 7.5 kW;

c) HJ20: 3 kW.

4. Some Explanations on Use of HJ Series Lengthwise H Beam Straightening Machine:

Lateral view on the mechanical frame of HJ series H Beam Straightening Horizontal Press Machine: (Fig.4)

1) The HJ series lengthwise straightening machine does not have function in overlapping with HYJ series and YTJ series H Beam Straightening Machine, which are used for straightening on H Beam flange deformation caused from SAW submerged arc welding: (Fig.5)

3) For practical application, if a piece of welding H Beam has deformation both on its flange and along its lengthwise direction, it could not to be finished straightening on the two types of deformation with either one type of the H Beam Straightening Machine. Under such condition, both the HYJ/YTJ and HJ series straightening machine should be used.