A. Usage, Application and Strong Points of the STB50 Model Single Axis Servo Drive Rotary Welding Table:

1. Usage of Tailor Made Turning Table Positioner:

1) This niche product of welding equipment works with Welding Robot, serving as a Single Axis Welding Positioner, for infinitely and continuously revolving workpieces within the angular scope of 0°~360°;

2) Drive: The revolve of workpieces is driven with 1.5kW servo motor;

2. Function of Servo Drive Single Axis Welding Positioner:

1) Its max. loading capacity is 500kg --- Light duty;

2) Applicable diameter of workpieces is from Φ500mm up to Φ1,700mm --- Wide range;

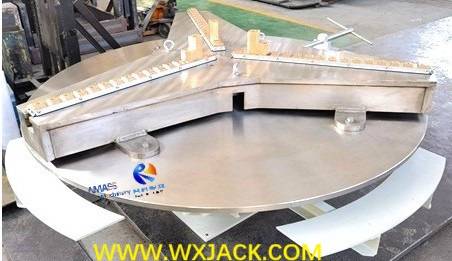

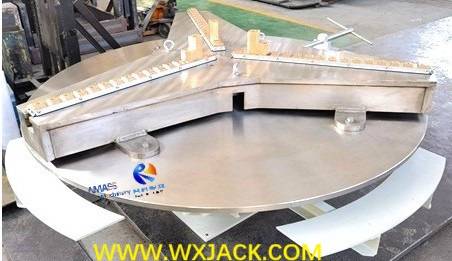

3) Fixation of workpieces onto the Rotary Welding Table is by means of 3 Jaw chuck Welding Fixture: (Fig.1)

3. Wide Application of Servo Drive Welding Turntable:

1) It is especially suitable for working sites with large volume production on small size components, with high degree of precision requirement, such as Flange/ Pipe Elbow, etc.;

2) Applicable Industries of this Servo Drive Welding Turntable are: Shipbuilding/ Military/ Precision Machinery, etc.;

3) In this business case, this set of servo drive welding machine tool was designed and produced for Chinese Military Plant, in the year of 2023 beginning by Wuxi JACK;

4. Strong Points of the Servo Drive Rotary Welding Table:

1) High Precision: It has top grade accuracy, on both workpiece rotation, and workmanship of the Turning Table Positioner and Welding Fixture itself;

2) High Standard Raw Material: The Rotary Welding Table and Welding Fixture of this Single Axis Welding Positioner are made from Stainless Steel and Alloy: (Fig.2)

3) Fixation of workpieces onto the Rotary Welding Table is secure and firm, without damage on the workpieces during loading/ unloading/ welding operation;

4) Operation and Service on the welding machine tool is convenient and user friendly, this includes ergonomics height for operator; Loading and Unloading/ Secure and Release of the workpieces, etc.;

5) Logistics: Integral Design of the Single Axis Welding Positioner makes it with compact size and solid structure, which is easy for transportation, relocation and placement;

6) Accommodating on Harsh Working Environment: The servo motor and servo driver have high degree of IP protection. So are other electric control elements, and mechanical system of the Servo Drive Rotary Welding Table.

B. Structure and Main Units of the STB50 Model Servo Drive Turning Table Positioner:

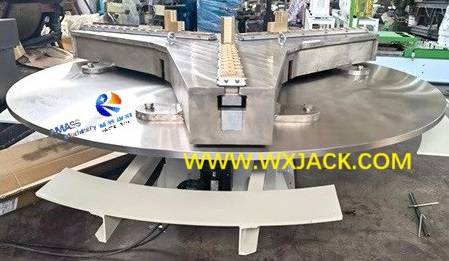

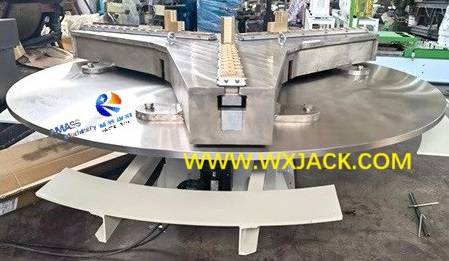

1.Structure: The overall appearance of the assembled Wuxi JACK Servo Drive Welding Turntable is shown in below: (Fig.3)

2. Check from the above photo, the Servo Drive Turning Table Positioner has 5 Main Units of:

1) Round shape mechanical base frame, for mounting the entire piece of welding machine tool, and customer prepared water channel;

2) Rotary Welding Table, which is core unit of the Single Axis Welding Positioner;

3) Slew Bearing: The central unit for rotation. It determines on smoothness and precision of Rotary Welding Table and workpiece rotation;

4) 3 Jaw Chuck Adjustable Welding Fixture: It is installed onto top surface of the Welding Turntable, for clamping workpieces perfectly in place firmly during fabrication;

5) Driving and Transmission Unit: This includes: Cables, Servo Driver and Motor, control and operating elements, as well as motor reducer.

C. Tailor Made Welding Fixture Equipped with the STB50 Model Servo Drive Welding Turntable:

1. Close up view on the 3 Jaw chuck Welding Fixture: (Fig.4)

2. Structure: As can be found from the above photo, this Welding Fixture has 3 pieces of branches, officially named as jaw chucks, with 120° apart from each other;

3. Way of Fixing Workpieces onto the 3 Jaw Chuck Welding Fixture:

1) There is a long length slot in each of the chuck branch;

2) There is a row of claws in each of the slot middle line;

3) These claws and slots are used for positioning different sizes of workpieces onto Welding Fixture in accurate position, which in turn onto Rotary Welding Table;

4) The exact location of these claws can be adjusted, based on diameter of the workpiece;

5) Final fixation of the workpiece onto the Servo Drive Turning Table Positioner is by means of a long piece rod, as shown in the above photo;

4. Anti-Corrosion: Made from Stainless Steel, the entire piece of Welding Fixture has been treated with anti-rust performance.

D. Technical Specialties and Tolerances of the STB50 Model Servo Drive Single Axis Welding Positioner:

1. Working Principle of Servo Drive Turning Table Positioner:

1) Guide: Slew bearing is installed beneath Welding Turntable for workpiece rotation transmission;

2) Drive: By means of servo motor and driver, and by way of gear couples, the Servo Drive Welding Turntable is driven into revolve;

3) Transmission: Revolve of the Rotary Welding Table and workpiece is transmitted with high precision planar reducer;

2. Revolve Tolerance of Servo Drive Rotary Welding Table:

1) When the servo motor works under the rated revolutionary speed of 3000rpm, the corresponding revolve speed of workpiece is 6 rpm;

2) The repetitive locating precision of workpiece is less than ±0.1°;

3. Mechanical System Tolerance in Single Axis Welding Positioner:

1) Diameter of the Rotary Welding Table is Φ1800mm, for fixing the max. diameter workpieces of Φ1700mm;

2) Made from Stainless Steel, surface of the Welding Turntable is precisely machined and heat treated, with flatness controlled within the tolerance of ±0.5mm;

3) Provide mechanical support of water channel, as part of supply range of this Servo Drive Turning Table Positioner.

E. Technical Parameters of the STB50 Model Single Axis Servo Drive Turning Table Positioner:

Summed up as below:

No. | Model | STB50 Servo Drive Rotary Welding Table |

1 | Max. Loading Capacity | 500 kg |

2 | Max. Loading Size | Diameter Φ1,700 mm |

3 | Revolve Angle Range | 0° ~ 360° |

4 | Revolve Speed Range | 0.06 ~ 6 rpm |

5 | Revolve Repetitive Accuracy | ±0.1° |

6 | Rotary Welding Table Diameter | φ1800 mm |

7 | Rotary Welding Table Flatness | ±0.5 mm |

8 | Workpiece Revolving Motor Power | 1.5 kW, Servo type |

9 | With 3 Jaw Clamp Chuck | One set, suit Diameter Φ300~ Φ1700mm |

10 | Revolve Speed Adjustment |

14Servo Management

|

11 | Control Box | One set remote control panel, with digital display |