1. Specialty and Usage of Electric Welding Turning Table:

1) Technical Feature: Electric Weld Turning Table is a kind of simplified single axis Welding Positioner. As you can find from attached photos, it removes tilting of Welding turntable from the standard single table top Welding Positioner, and keeps the infinite 0°~360° revolve of Weld turntable and workpiece with speed control;

2) Usage: In this way, this Electric Welding turntable makes workpiece revolving in its horizontal surface, around vertical axis, or axis of certain fixed angle, for the purpose of Welding, Hard facing, or Cut of cylindrical parts;

3) Application: In this respect, this simplified Welding Positioner is a kind of general purpose Welding Turning Table, which has extensive practice in the industry.

2. Put into Use of Electric Welding Turning Table:

1) Related Welding Equipment: This simplified one control axis Electric Welding Positioner can be used as a set of individual welding machine, which means works independently, or as a supplementary unit in a complete group of Welding Center, coordinating with other welding equipment, such as Welding Rotator, or Welding Column and Boom, etc.;

2) Main Motion Units in Electric Weld Turning Table:

a) Revolving Electric Weld turntable is the execution mechanism of this one control axis Welding Positioner;

b) The Welding turntable here has the same exterior and internal structure as that of the Single Table Top Welding Positioner: A set of slewing support is also used for driving the Welding Turntable and workpiece into rotation;

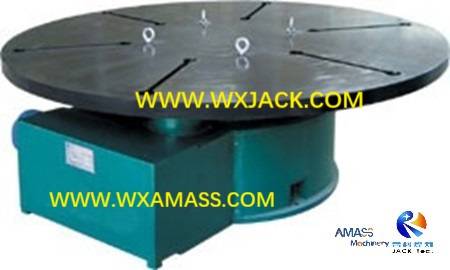

c) Same as the two axis single worktable Welding Positioner, there are 6 pieces of T slots cut in the surface of the Weld Turning Table, for firmly fitting and securing workpiece of various sizes and species;

Worktable and its cut 6 pieces of T slots: (Fig.1)

d) Assistant Function Unit: Special fixture is also necessary to be applied here to fix the workpiece.

3. Technical Characteristics of Electric Weld Turning Table:

Technical description of this welding equipment:

1) Control Axis: It has only one degree of freedom for workpiece revolve, as the above mentioned;

2) Welding Speed Control:

In most majority conditions the revolve speed of the Weld turntable, which is also welding speed of workpiece, is adjustable controlled with inverter, meeting the requirement of welding technology;

3) Loading Capacity of the Electric Weld turntable:

a) There are various of loading tonnage available with this series of variable speed one control axis Welding Positioner;

b) The often used specifications are 2 Ton, 3 Ton, 5 Ton, and 10 Ton loading capacity of the Welding Turning Table. Heavier than this specification should be classified as heavy duty models. Currently in industry the max. loading tonnage is 50 Ton.

4. Deceleration Mechanism in One Control Axis Welding Positioner:

1) This variable speed Welding turntable usually has broad range of reduction ratio: It is usually kept at 330:1;

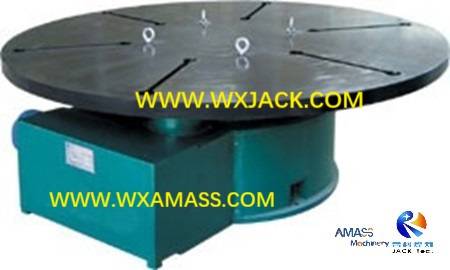

Motor reducer base: (Fig.2)

2) For this reason, secondary deceleration is often introduced here to this Electric Welding Turning Table. Please check the above picture: One side of the Welding turntable base bed is worm gear reducer, and the opposing side is cycloidal pin wheel reducer;

3) With such combinational reduction unit adopted, the ideal reduction ratio can be met in this One Control Axis Welding Positioner.

5. Equipment Mechanical Structure of Electric Welding Turntable:

Also, as can be seen from the above picture, the motor and reducers are put at both sides of Electric Welding turntable base bed. Such kind of design has at least three advantages of:

1) Maintain stable gravity center of the entire set of Welding Turning Table;

2) Such symmetrical deployment of the heavy duty motor and reducer makes good appearance of the entire set of large welding Turning Table;

3) The entire unit of driving and transmission system will not extend beyond base bed of the Electric Welding turntable. In this sense, it saves land and space occupation in the workshop.

6. Durability of Electric Welding Turning Table:

Besides the conductive device which is an indispensable unit equipped into all kinds of Welding Positioner, this Electric Welding Turning Table also shares the common strong point of good Grounding, Water connection (if necessary), Gas connection (if necessary), Heat conduction and Ventilation.

7. Technical Parameters of Electric Welding Turning Table:

Electric Welding Turntable |

Degree of Freedom | 0°~360° infinite revolving with speed control |

Weld Turning Table Revolving Speed | 0.2 ~ 2 rpm, controlled with inverter |

Available Loading Tonnage | 2 Ton, 3 Ton, 5 Ton, and 10 Ton, up to 50 Ton |