1. The Purpose of this Product Section on General Purpose Welding Positioner:

This product section gives sum up on the group of Single Table Top Welding Turning Table which has the most extensive use in industry.

2. Framework and Structure of General Purpose Weld Positioner:

The key words describing this product family of generic Welding Positioning Machine can be attributed as:

1) Configuration of Single Welding Turning Table (or Single Worktable);

2) Motor Drive (or Electric) for workpiece 0°~ 360° infinite revolve;

3) Two or three degrees of freedom: Standard configuration of welding turntable 0°~360° revolve and 0°~115° tilt, as well as optional welding turntable elevation function. For detail, please check product section of “Single Table Top Manual Vertical Elevating”;

4) Welding Turning Table revolve linear speed is adjustable, or in variable speed, controlled with A.C. inverter;

5) Top surface of Welding Turning Table in Universal Welding Positioner is cut with several lines of T slot, and equipped with certain type of chuck for fixing workpiece.

Welding Turning Table: (Fig.1)

3. Two Critical Parameters for Normal Running of Universal Welding Positioner:

Of all the technical specifications of this Universal Weld Positioner, there are two core and requisite parameters which must be paid attention to:

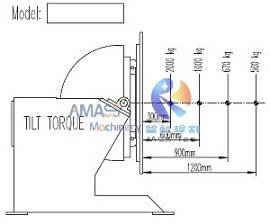

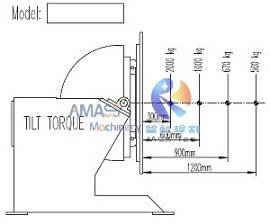

1) Max. Gravity Center Distance: (Fig.2)

This involves 0°~115° tilt capability of the Welding turntable: In the case of exceeding this tolerance, the Universal Welding Positioner does not have sufficient torque to drive the workpiece into tilting;

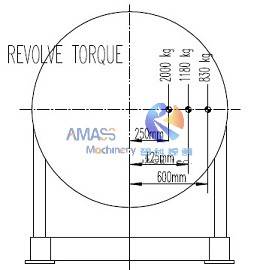

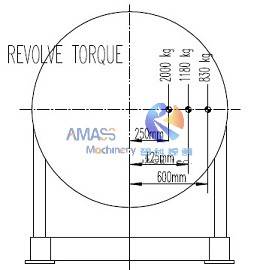

2) Max. Eccentricity Center Distance diagram: (Fig.3)

This involves 0°~360° revolve capability of the Welding Turning Table. Which means, in the case of exceeding this tolerance, the Universal Welding Positioner does not have sufficient torque to drive the workpiece into revolve.

4. Slewing Support in Wuxi JACK General Purpose Welding Positioner:

As shown in below 2 photos: (Fig.4,5)

1) Slewing support is the critical working unit in the whole range of the welding positioning equipment;

2) Slewing support is for supporting and making Welding Turning Table and workpiece into 0°~360° infinite revolve;

3) The slewing support used is of Single Ball type;

4) The slewing support is made by professional manufacturer. As the working unit determining performance of the Welding Positioning Machine, it has the strong points of reasonable structure, good rigidity, light deadweight, and long service life;

5) This type of slewing support is sealed with seal ring which is made of heat resistant rubber. With this seal ring, it avoids the issues of lubricating oil leakage and foreign dust infiltration, protecting the slewing ring against potential harm caused from rigorous working surroundings of the Universal Welding Positioner.

5. Conductive Device in General Purpose Welding Positioner:

As shown in below photo: (Fig.6)

1) Conductive device is another standard configured unit with chuck;

2) Conductive device is for forming up conductive circuit of welding ground wire, and providing electricity for revolve drive motor of the Welding Turning Table;

3) There is insulation between this conductive unit and Welding turntable;

4) The conducting rod in the conductive device is made of brass, making long using term of the device: The same service life as the Welding Positioning Machine itself;

5) Correspondingly, there is an important parameter with this series of All Purpose Welding Positioner with chuck: Conductivity. For example, 1000A or 1500A.

6. Supplementary Tools for Running of General Purpose Welding Positioner:

1) Protection Cover for Welding Turning Table:

There is protection cover for the drive and transmission unit with chuck;

2) Supplementary Tools Applied for Large Size Welding Positioner:

Sometimes auxiliary tools, such as climbing ladder is used, in the case of heavy duty All Purpose Welding Positioner with chuck. For detail, please check product sections of:

Heavy duty Single Table Top Large Universal model;

Heavy duty Double Table Top Lifting and Rotation Large model

7. Technical Parameters of General Purpose Welding Positioner:

HB Series Single Welding Turning Table Industrial Rotary Universal Welding Positioner with Chuck |

Model | HB1 | HB3 | HB6 | HB12 | HB20 | HB30 | HB50 | HB80 | HB100 | HB150 | HB200 | HB300 | HB500 |

Loading (kg) | 100 | 300 | 600 | 1200 | 2000 | 3000 | 5000 | 8000 | 10000 | 15000 | 20000 | 30000 | 50000 |

Revolve speed (rpm) | 0.1-1 | 0.2-2 | 0.1-1.1 | 0.1-1 | 0.1-1 | 0.08-0.8 | 0.07-0.7 | 0.06-0.6 | 0.06-0.6 | 0.05-0.5 | 0.05-0.5 | 0.04-0.4 | 0.04-0.4 |

Tilt speed (rpm) | 2 | ≈0.9 | ≈0.8 | ≈0.5 | ≈0.4 | ≈0.3 | ≈0.2 | ≈0.14 | ≈0.14 | ≈0.14 | ≈0.14 | ≈0.10 | ≈0.10 |

Work-table diameter (mm) | φ400 | φ600 | φ800 | φ1000 | φ1200 | φ1400 | φ1600 | φ2000 | φ2000 | φ2200 | φ2500 | φ3000 | φ4000 |

Max. Eccentricity (mm) | 100 | 150 | 150 | 200 | 250 | 250 | 250 | 200 | 200 | 200 | 200 | 200 | 200 |

Max. Gravity Center Distance (mm) | 150 | 200 | 250 | 250 | 300 | 400 | 400 | 400 | 400 | 500 | 630 | 630 | 800 |

Worktable Tilt Range | 0°-120° |

Revolve Diameter at 900 mm | ≤600 | ≤1000 | ≤1500 | ≤1500 | ≤2000 | ≤2300 | ≤2800 | ≤3200 | ≤3200 | ≤3400 | ≤3400 | ≤4200 | ≤5700 |

Speed Adjustment | Revolve speed is VFD. Tilt speed is constant (Ordinary brake motor) 14

|