Application and Working Site of Z15 I H Beam Assembly Machine:

Background: The Z15 Automatic H Beam Assembly and Tack Welding Machine in the attached first photo was taken on an exported automatic I H Beam Production Line produced by Wuxi JACK.

1. The Usage of Z15 Automatic H Beam Assembly Machine:

1) Application: Z15 Automatic I Beam Assembly Machine is the basic, indispensable, and the most widely used H Beam Production Machine;

2) Process Step: This H Beam Production Machine initiates on the first step in the process of welding H Beam production:

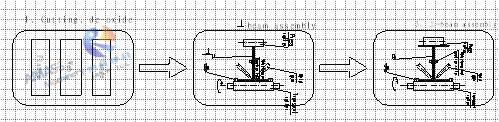

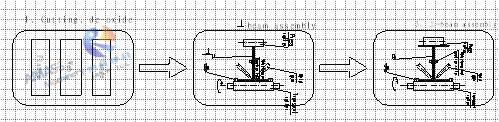

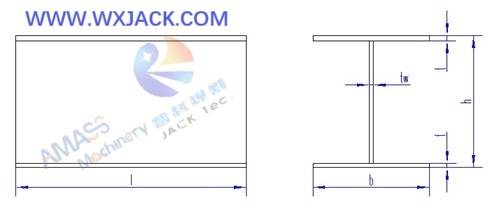

Process technology route of Z15 Automatic I Beam Assembly and Tack Welding Machine: (Fig.1)

a) T Beam Assembly: Assembles one piece of flange and one piece of web into “ ┷” Beam, or inversed T Beam;

b) H Beam Assembly: Flip the assembled T Beam 180°, and assembles the second piece of flange, making the workpiece into a piece of H Beam;

3) “Complicated” Electric Logic Control in Automatic H Beam Assembly Machine:

Of all the Three Basic Steps of H Beam Production Machine:

a) Z H Beam Assembly Machine;

b) LHC/ LHA/ LHT H Beam Submerged Arc Welding Machine;

c) HYJ/ YTJ H Beam Flange Straightening Machine,

The H Beam Assembly Machine is the most complicated one in terms of logic control of machine working steps, which utilizes PLC (Programmable Logic Controller) as its core control unit;

4) Assembly Style of H Beam Assembly Machine:

As introduced in the product category of Z series H Beam Assembly Machine, on the aspect of alignment style of web and flange (Which in essence is assembling way of the I Beam Assembly Machine), it has two types of:

a) Self alignment H Beam Assembly Machine (Automatic control);

b) Manual alignment I Beam Assembly Machine;

5) Characteristics of Z15 H Beam Assembly and Tack Welding Machine:

Z15 automatic control can be viewed as “Standard” model of H Beam Assembly Machine, because of below two factors:

a) Max. H Beam Web Height: One is because the max. allowable H Beam size of 1500mm web height produced from the Z15 Automatic H Beam Assembly Machine, is the most popular dimension of H Beam Production Machine in Steel Structure Industry;

b) Control Way: The second reason is working mode of automatic assembling and automatic CO2 welding is the most preferred configuration by customers.

2. Working Process Feature of Z15 Automatic H Beam Assembly and Tack Welding Machine:

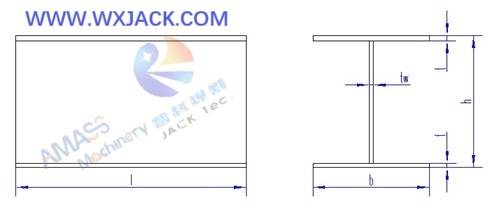

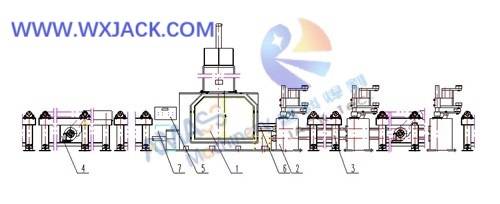

1) Design illustration on H Beam Production Machine Z15 Automatic H Beam Assembly and Tack Welding Machine: (Fig.2)

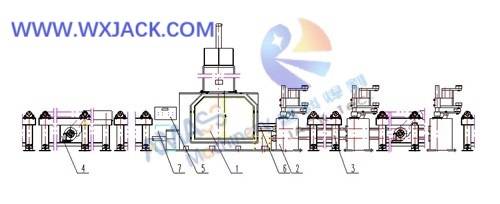

2) Accurately assembling H Beam in Z15 Self Alignment Automatic I Beam Assembly Machine: (Fig.3)

3) Assembly Style: In the automatic welding period of the Z15 H Beam Assembly and Tack Welding Machine, when the H Beam is clamped with symmetrical arranged rollers driven with hydraulic unit, two sets of CO2 welding power supply perform tack welding at both sides of H Beam simultaneously:

Cross view on working cell of I Beam Assembly Machine: (Fig.4)

CO2 welding power supply of H Beam Assembly and Tack Welding Machine: (Fig.5)

4) PLC Control: The whole process of workpiece Feeding, Assembly and Tack welding are all controlled with PLC in the electric control system of Z15 I Beam Assembly Machine, featuring in good precision and high automation:

Welding torch motion is controlled with PLC in I H Beam Assembly Machine: (Fig.6)

5) Process Parameters: Besides, the process control parameter of the H I Beam Assembly Machine, such as length of each segment of CO2 welding seam, welding velocity, etc. can be modulated by editing program of the PLC, based on practical working site of this H Beam Production Machine;

3. Technical Parameters of Z15 H Beam Assembly Machine:

Below are specifications of Z15 Automatic H Beam Assembly and Tack Welding Machine:

Model | Z15 Self Alignment Automatic H I Beam Assembly and Tack Welding Machine |

H Beam Web Height (mm) (mm) | 200 ~ 1500 |

H Beam Web Thickness (mm) | 6∽32 |

H Beam Flange Width (mm) | 200∽800 |

H Beam Flange Thickness (mm) | 6∽40 |

H Beam Length (mm) | 4000∽12000 |

Max. H Beam Weight | 20 Ton. |

Assembly Speed (m / min.) | 0.5 ~ 6 |

Web and Flange Alignment Style | Self Alignment controlled with PLC |

Input Conveyor Length (mm) | 2600 x 3 |

Out Conveyor Length (mm) | 2600 x 3 |

Tack Welding Style | Automatic CO2 tack welding controlled with PLC |