1. Specialty and Characteristic of HGK Series Adjusting Welding Rotator by Leadscrew:

The Adjustable Welding Rotator by Leadscrew is the refinement version in product family of Welding Roller Bed, in view of:

1) Structure:

Center span (distance) of Welding Turning Roller, which corresponds with applicable diameter of cylindrical workpiece, is controlled by means of manual turning leadscrew:

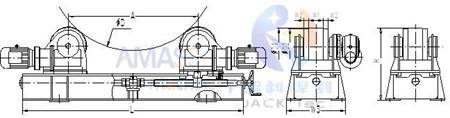

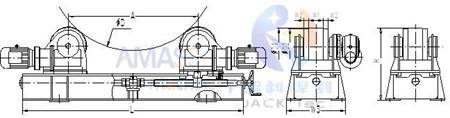

Handwheel for turning and adjusting leadscrew: (Fig.1)

2) Loading Capacity of HGK Series Adjusting Welding Roller Bed by Leadscrew:

a) Light to medium duty: Loading weight is confined to 60 Ton in ordinary standard model;

b) This belongs to medium duty Welding Roller Bed. In this respect, we can say that there is no heavy duty version in sub group of the HGK series leadscrew adjustable.

2. Brief on HGK Series Adjustable Welding Rotator by Leadscrew:

1) Way of Welding Turning Roller Center Distance Adjustment:

From its product name we can know that, this is implemented with manually turning leadscrew;

2) Driving Mode:

Same as the HGZ series Self Adjustable, the universal HGK models leadscrew adjustable is also composed of one set of driving section Welding Roller Bed (Motor installed for driving roller revolving), and one set of idle section (or follower).

3. Difference between HGK Series Leadscrew Adjusting and HGZ Series Self Adjustable Welding Roller Bed:

There are certain obvious changes with the HGK series Adjustable Welding Rotator by Leadscrew, covering structure and working mode. See below:

Design sketch: (Fig.2)

1) Structure Difference in Two types of Welding Rotator:

a) For a set of HGK models leadscrew adjusting type, the leadscrew is installed inside the cavity of the Welding Roller Bed, with a handwheel connected with it and fit at the lateral external side of the Welding Rotator;

b) Another obvious disparity compared with the HGZ self adjustable type is its quantity of turning rollers: Please check attached picture. There is only piece of Welding Turning Roller in leadscrew adjusting Welding Roller Bed, compared with four pieces in self adjustable type. Please check the illustration in the product section of “Middle Level Loading Capacity HGZ Series Self Adjusting”;

c) This is the reason that, with light duty and medium duty leadscrew adjustable type, its turning roller material can be either combined PU and metallic rollers, or full metallic rollers:

Rubber Welding Turning Roller: (Fig.3)

Fully Metallic Welding Turning Roller: (Fig.4)

2) Welding Turning Roller Distance Adjustment:

a) For managing on this series of leadscrew adjusting type, first set a target value of leadscrew movement. For example, 1500mm;

b) Then turn the handwheel of the leadscrew until it reaches the target value;

c) Confirm on stroke of the leadscrew is made with tools, such as tape measurement;

d) For small type (light duty) leadscrew adjust Welding Rotator, sometimes we paste indication mark and ruler on the Welding Roller Bed.

4. Classification on HGK Series Adjustable Welding Turning Roller by Leadscrew:

1) Same as Self Adjusting type, this HGK series leadscrew adjusting type also has basic standard structure of stationary version Welding Roller Bed;

2) Besides, there are several variations with these welding equipment: For example, Motor drive Leadscrew type, Manual or Motor drive moving type, Down Pressure type…, etc.;

3) For these special design models, we will have presentation in subsequent product sections for descriptions.

5. Technical Parameters of HLK Series Adjusting Welding Rotator by Leadscrew:

Standard Models of HLK Adjustable Welding Rotator by Leadscrew |

Model | HGK2 | HGK5 | HGK10 | HGK20 | HGK40 | HGK60 |

Max. loading (Ton) | 2 | 5 | 10 | 20 | 40 | 60 |

Workpiece Size(mm) | D | ø250~1800 | ø 250~2300 | ø 320~2800 | ø 500~3000 | ø 600~4200 | ø 700~5000 |

Roller diameter and width (mm) | PU roller | D1 | 200 | 250 | 300 | 350 | 400 | 450 |

W1 | 80 | 100 | 120 | 120 | 120 | 120 |

Metallic roller | D2 | 190 | 240 | 290 | 340 | 392 | 444 |

W2 | 16 | 20 | 38 | 45 | 50 | 70 |

Linear speed(mm/min.) | 100-1000 VFD |

Motor power(kW) | 2×0.18 | 2×0.37 | 2×0.55 | 2×1.1 | 2×1.5 | 2×1.5 |

Roller distance (mm) | A | 300~950 | 400~1300 | 480~1400 | 600~1800 | 800~2000 | 880~2200 |

Besides above specifications, also we can design special model based on customer requirement. |