1. Brief on Usage and Working Way of the Gantry Frame Submerged Arc Welding Equipment:

1) As its name implies, this Gantry Welding Equipment is for doing long straight longitudinal submerged arc welding, on large size structure members, such as municipal use lamp post;

2) This Gantry Frame Submerged Arc Welding Equipment has similar structure and working way as H Beam Gantry Welding Machine, but with more complicated structure, and for wider range of larger size workpieces.

2. Main Units in the Gantry Frame Longitudinal Seam Welding Equipment:

1) Welding Torch Adjustment unit in the SAW Gantry Welding Equipment:

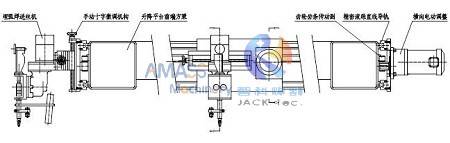

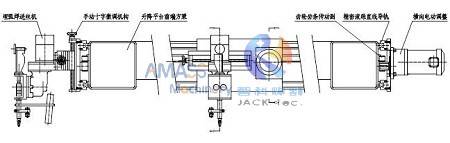

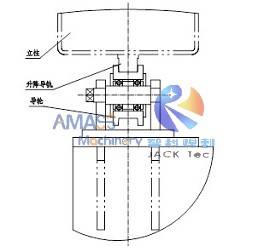

Please check attached picture and below sketch for checking its structure: (Fig.1)

a) Considering this Special Purpose Welding Equipment can not only be used for welding electric light pole, but also other long and large workpieces, such as BOX Beam/ Girder. So, the welding torch should be capable of traveling in extensive range;

b) For this reason, the front beam of the elevating platform of the Gantry Welding Equipment is finely machined, and fit with precise linear ball bearing, for guiding transverse long distance movement of the welding torch and its carriage;

2) Welding Torch Carriage Movement in the Submerged Arc Welding Equipment:

a) Movement of the welding torch carriage is driven with motor reducer and transmitted with gear rack couple;

b) During operation of Long Straight Longitudinal Welding Machine, to make sure precise and accurate seam tracing with the welding torch, there is a set of manual cross slide inching adjustment unit, making the torch tip right above welding seam all the while;

c) SAW flux barrel and hopper of the Gantry Frame Submerged Arc Welding Equipment are installed right above the welding carriage, and moves along together with the carriage during the long straight longitudinal seam welding. In this way, the flux hopper always is located directly above the welding torch where ever it goes, making fluent conveying of flux without interruption;

3) The Intermediate Up and Down Platform in the Gantry Frame Longitudinal Seam Welding Equipment:

a) This is the working table and central unit of the large size SAW Gantry Welding Equipment;

b) Considering large size of the box gantry frame of the Submerged Arc Welding Equipment, guaranteeing steady and stable elevation of the platform is very important during its running. For this purpose, there is one set of motor reducer at the middle of the platform, with a piece of shaft delivering transmission to its both sides;

c) There are two sets of motor reducer (One set at each side) at both sides of the platform. To cater for diameter of the workpiece in the Gantry Frame Longitudinal Seam Welding Equipment, the platform can be moved up and down smoothly in constant speed, which is transmitted by means of leadscrew and nut couple;

d) In this SAW Gantry Welding Equipment, platform elevation is guided with precise machining guideway. The guideways are welded onto the four columns of the box gantry frame. Besides, guiding rollers of the guiderail has eccentric shaft, for making inching adjustment on pressing condition of the guiding rollers;

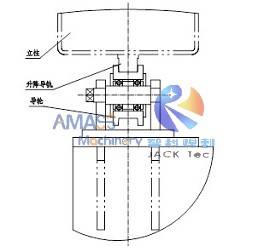

e) Below sketch gives assembly way of the guideway and its guiding roller for the elevating platform, in the Gantry Frame Submerged Arc Welding Equipment: (Fig.2)

4) Workpiece Support in the Long Straight Longitudinal Welding Machine:

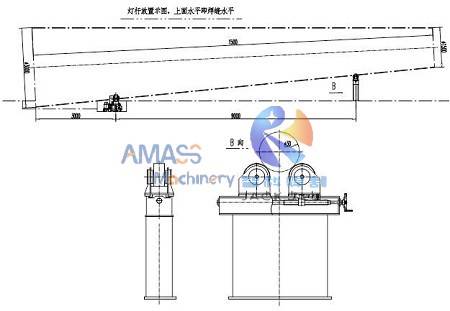

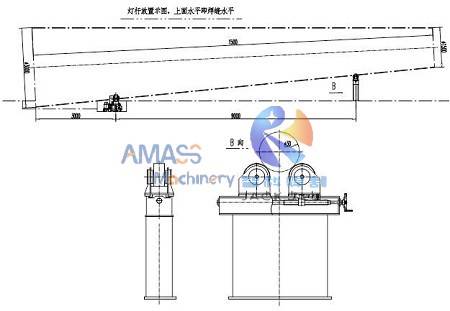

Please check attached picture and below sketch for observing laying out of the workpiece in this Special Purpose Welding Equipment: (Fig.3)

a) As can be seen from the sketch, the long and large size workpiece is supported with two sets of Roller Bed. Of which the large end side is driving type, and the small end side is idle type with adjusting leadscrew;

b) To make sure perfect horizontal position of welding seam in the Longitudinal Seam Welding Equipment, the larger end driving roller bed should be embedded inside a pit in the workshop floor; The smaller side idle roller bed should also be equipped with lifting function;

c) To fully guaranteeing horizontal levelness of welding seam delivered from the SAW Gantry Welding Equipment, besides the adjustable span between the two rollers at idle side, a supporting rack should be used at its beneath;

5) Safety Unit in the SAW Gantry Welding Equipment:

a) For operating this large size Special Purpose Welding Equipment, safe operation is of vital importance;

b) At lateral side of the box gantry frame, there is a staircase surrounded with guardrail. Operator can climb onto the elevating platform in safe condition;

6) Welding System in the Gantry Frame Submerged Arc Welding Equipment:

a) The long straight longitudinal submerged arc welding calls for high standard and consistent welding operation, delivered from this Long Straight Longitudinal Welding Machine;

b) Grounding cable is joint with workpiece from SAW power supply directly;

c) Reliable connection of welding circuit, together with stable current and voltage produces uniform high quality welding seams from the Submerged Arc Welding Equipment;

d) Control console of SAW welding power supply is installed on the front beam of elevating platform in the Gantry Frame Submerged Arc Welding Equipment, for easy access and convenient operation.

3. Specification and Parameter of Gantry Frame Submerged Arc Welding Equipment:

Please check below for workpiece specification and parameters of this Special Purpose Welding Equipment:

Gantry Frame Longitudinal Seam Welding Equipment |

Workpiece Length L | 9000 ~ 16000 mm |

Large End Diameter D | ≤2500mm |

Small End Diameter d | ≥300mm |

Workpiece Taper | a=8°(a=(D-d)/L) |

Workpiece Weight | ≤6000kg |

Gantry Travel Speed (Welding Speed) | 200 ~ 2000 mm/min. |

Gantry Travel Drive Motor | 2 x 1.1kW, double drive |

Gantry Travel Rail | 24kg/m, precise honing |

Welding Torch Transverse Moving Motor | 0.2 kW |

Platform Elevating Motor | 2.2 kW |

Platform Elevating Speed | 1500 mm/min. |