A. Machine Tools and Workpieces of HB2000 Semi-Automatic H I Beam Production Equipment Line:

1. Features: This manual arrangement and automatic running production line adopts the largest standard model of welded H I Beam Production Machine, producing this widely applied steel structure parts with web height up to 2000mm;

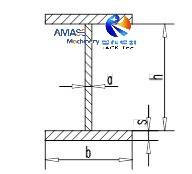

1) Cross section of welded H Beam: (Fig.1)

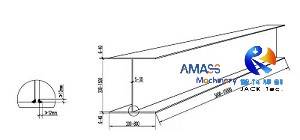

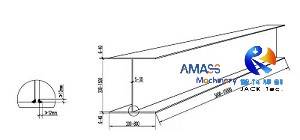

2) The entire piece of welded H Beam: (Fig.2)

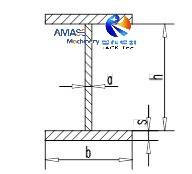

3) The vertical orientation welded H Beam produced: (Fig.3)

2. Main H I Beam Production Machine in HB2000 Semi-Automatic Line:

1) Z20 model H I Beam Assembly and Stitch Welding Machine;

2) H I Beam Gantry Welding Machine:

a) LHA55Z model Center control type, or

b) LHA5C model side control type, or

c) LHT model T type,

Either of the above three models has capability of fabricating welded H Beam of web height up to 2000mm. And, considering as less operator as possible, so as to saving variable labor cost at customer facility, we recommend LHA55Z, or LHT model, which involves only one operator for operating the machine;

3) HYJ-40 model H I Beam Straightening Machine for flange straightening;

3. Content of Product HB2000 semi-Automatic H Beam Production Line:

As supplementary on the preceding section of HB1800, at this segment of HB2000, we will go on below topics of:

1) Environment Health Safety in running;

2) Hoist of material among H I Beam Production Machine;

3) Workshop power capacity;

4) Machine installation.

B. Environment Health Safety in Operation of HB Series Welded H I Beam Production Equipment Line:

1. Significance and Potential Risk:

1) Importance: Today EHS (Environment Health Safety) is important department in a facility of production industry. It is the basis and starting point of successful business running;

2) Hidden Risk: During running of heavy machinery HB1500/ HB1800/ HB2000 Welded H I Beam Production Machine, there exist potential risks of squeeze, bump, crash, eye harm, noise on operators, in daily working:

3) Operators at working site of Wuxi JACK YTJ-60 hydraulic drive H I Beam Straightening Machine: (Fig.4)

2. Proper PPE at H I Beam Production Equipment Line:

PPE, short for Personal Protective Equipment, should be put on all the while in the process of welded H Beam production Line, including

1) Hard shoes in all the area of workshop;

2) Safety glasses in all the area of workshop;

3) Helmet when there is traveling crane overhead;

4) Facial mask for gas shielded CO2 welding at H I Beam Assembly and Stitch Welding Machine, which generates large sum of arc radiation in the process;

Strong arc light and heavy fume during CO2 welding: (Fig.5)

5) Ear plug where there is heavy noise, especially at H I Beam Straightening Machine work station;

3. As summary, there is safety regulation in detail at beginning of each manual of our Wuxi JACK H I Beam Production Machine. Be sure to read it before putting into use.

C. Hoist Materials among Work Stations of Welded H I Beam Production Machine:

1. Logistics Tools:

Because this is a semi-automatic line, which means there is 60° / 90° / 180° overturning equipment and conveying cart as in the case of automatic line, large lifting equipment and forklift are necessary for hoisting and transporting workpieces (Flange, web, T Beam, H Beam) into place, and among machines for:

1) H Beam assembly and CO2 tack welding;

2) H Beam SAW submerged arc welding;

3) H Beam flange and longitudinal Straightening Machine;

2. Qualified and certified personnel to take on the conveying job along the entire production line;

3. During operation, operators should abide by local lifting rules.

D. Workshop Power Capacity of HB2000 Welded H I Beam Production Equipment Line:

1. Electricity Consumption of Each H I Beam Production Machine:

1) Z20 model H I Beam Assembly and Stitch Welding Machine: Around 45kW (18.7kW for machine, and 2x 12.8kW for CO2 welding Power Source;

2) LHA55Z or LHT model H I Beam Gantry Welding Machine: Around 180kW (9kW for machine, and 2x 80kW for SAW power source, as well as 2x 5.5kW for Flux Recovery Unit);

3) HYJ-40 model H I Beam Straightening Machine: Around 25kW;

2. Summing up, the above three core H Beam Production Machine have total power of 250kW. So, workshop of semi-automatic HB2000 production line for large welded H Beam should have 300~350KVA capacity;

E. Technical Parameters of HB2000 Semi-Automatic Welded H I Beam Production Equipment Line:

Model | HB2000 Semi-Automatic Welded H I Beam Production Machine Group |

Max. H Beam Web Width | 2000 mm |

Applicable H Beam Web Thickness Range | 6∽32 mm |

Applicable H Beam Flange Width Range | 200∽800 mm |

Applicable H Beam Flange Thickness Range | 6∽40 mm (Special thickness of 40~80mm also available) |

Applicable H Beam Length Range | 4000∽12000 mm |

Max. Weight of H Beam Delivered | 20 Ton. |

H I Beam Assembly and Stitch Welding Machine | Z20 model fully automatic, for H Beam fitting up and stitch welding |

H I Beam Gantry Welding Machine | LHA55Z, or LHA5C, or LHT model, large welding current SAW |

H I Beam Straightening Machine | HYJ-40 model motor drive type |

Transfer of H Beam workpiece among stations | Manual labor, by means of travel crane |