1. Feature of HGZ Models Standard type Self Adjusting Welding Rotator:

1) This category is the basic type and standard structure Self Adjusting Welding Roller Bed, which has the most extensive application in industry in practical use;

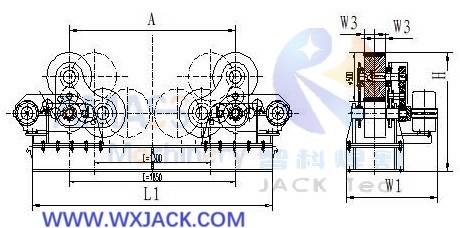

2) Draft sketch please see below sketch: (Fig.1)

3) The distinction of HGZ Series Self Adjustable Weld Rotator:

a) One group of Welding Roller Bed has four pieces of welding turning rollers: In the form of two pairs, and two pieces in each pair;

b) Compared with two pieces of welding turning rollers in HLK series bolt adjusting and HGK series leadscrew adjusting type equipment.

2. Working Manner of HGZ Models Standard type Self Adjustable Welding Rotator:

1) Product Structure of HGZ Series Self Adjusting Weld Rotator:

a) As you can check from the above sketch and attached photos, one set of the Self Adjusting Welding Rotator has 2 sets of Welding Roller Bed: One set of driving section (Installed with motor), and the other set of idle section (Follower type);

b) These 2 sets of Self Adjustable Welding Roller Bed are installed onto the 2 sets of stationary base bed (Pedestal) respectively. For this series product, we usually call these self adjusting Welding Roller Bed as “Plier shape racks”:

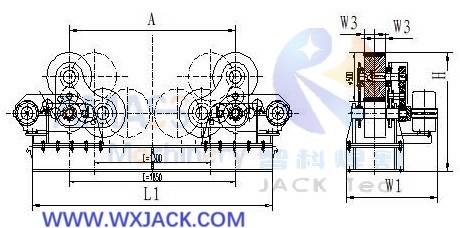

Plier shape racks of 4 pieces of welding turn rolls: (Fig.2)

c) The two sets of plier shape racks can revolve automatically along its shaft, to adapt to workpieces of various diameter loaded onto the Self Adjustable Welding Rotator. After the workpiece is put onto the plier shape racks, and under the effect of deadweight of the workpiece, the plier shape racks will revolve its angle automatically and accordingly;

2) Rotating Linear Speed of Turning Rollers in Self Adjustable Weld Rotator:

a) This is the welding speed, which is the crucial process control parameter.

A.C. inverter and digital display for controlling and displaying on welding speed: (Fig.3,4)

b) This linear rotating speed can be adjusted with A.C. inverter, and shown in digit display. This rotating linear speed, or welding speed of the Self Adjusting Welding Rotator can be managed by operator by means of turning the grey color speed control knob (Please check the above photo), based on welding technology and practical condition;

3) Specification of HGZ Models Standard type Self Adjusting Weld Rotator:

a) Because these professional welding machine tool are fixed type on the ground, it can be viewed as stationary Welding Rotator, which is contrasted with the HGZ model traveling type Welding Roller Bed that will be discussed in the subsequent product section;

b) Loading Capacity for Workpiece: Please check below technical parameter. There is a chain of standard tonnage with these stationary Weld Rotator, from 5 Ton to 250 Ton, see below table;

c) This HGZ series has standard structure and outsourcing components. And we can design and produce special made Self Adjusting Welding Rotator products for customer need.

3. Technical Parameters of HGZ Standard type Self Adjusting Welding Rotator:

HGZ Standard type Self Adjustable Welding Roller Bed |

Model | HGZ5 | HGZ10 | HGZ20 | HGZ40 | HGZ60 | HGZ80 | HGZ100 | HGZ150 | HGZ200 | HGZ250 |

Max. loading (T) | 5 | 10 | 20 | 40 | 60 | 80 | 100 | 150 | 200 | 250 |

D3 (mm) | 760 | 910 | 1160 | 1390 | 1540 | 1720 | 2000 | 2400 | 2860 | 3000 |

Workpiece (mm) | d | 250 | 320 | 450 | 600 | 750 | 850 | 1000 | 1200 | 1500 | 1600 |

D | 2300 | 2800 | 3500 | 4200 | 4800 | 5000 | 5500 | 6500 | 8000 | 8500 |

Roller size | R PU roller (mm) | D1 | 250 | 300 | 350 | 400 | 450 | 500 | 500 | 550 |

|

|

W3 | 100 | 120 | 120 | 120 | 120 | 120 | 120 | 120 |

|

|

Metallic roller (mm) | D2 | 244 | 294 | 344 | 394 | 444 | 494 | 494 | 540 | 540 | 550 |

W4 | 20 | 25 | 30 | 40 | 50 | 60 | 70 | 100 | 100 | 120 |

Linear speed (mm/min.) | 100-1000 VFD |

Motor power(kW) | 0.75 | 1.1 | 1.5 | 3 | 4 | 4 | 5.5 | 5.5 | 7.5 | 7.5 |

Roller span A (mm) | 900 | 1100 | 1350 | 1600 | 1800 | 2000 | 2200 | 2600 | 2960 |

|

Above are the standard parameters of Self Adjusting Welding Rotator, also we can design special one on customer requirement. |