A. Usage and Application of High Precision GMAW Welding Center:

1) Where Used: The Automatic Welding Center of this section, as its name implies, is for welding small diameter and short length stainless steel cylindrical parts;

2) The welding mode is TIG/ GMAW;

3) Workpieces: This High Precision GMAW Welding Center is for delivering the sealed cylinders used in a pharmaceutical plant.

B. Technical View on This Automatic Welding Integrated Station:

1. Workpiece to be Welded in High Precision GMAW Welding Center:

1) This Automatic Welding Integrated Station is for carrying out circumferential and longitudinal seam welding, on stainless steel pipes;

2) The thickness of stainless steel pipes is up to 10mm, length up to 2000mm;

3) So, it is a Light duty welding equipment group.

2. This Automatic Welding Center Consists of:

1) One set of LHZ3030 model Medium duty Fixed Manual Revolving Welding Manipulator;

2) One set of 2 Ton loading capacity Leadscrew Adjusting Welding Rotator;

3) One set of Panasonic 500GL5 welding power supply together with welding wire feeder.

3. Technical Specifications of the High Precision GMAW Welding Center:

1) Welding Wire: The welding wire used in this Welding Center can be either solid or flux wire, of Φ1.2mm/ Φ1.4mm/ Φ1.6mm;

2) Upright Column Manual Revolve: Considering there is only working station in the Welding Integrated Station, the Welding Manipulator is of medium duty fixed manual revolving type. The function of column revolve is considered for the convenience of future expansion;

3) Ergonomics: As can be seen in the attached pictures, the 2 Ton loading capacity Leadscrew Adjusting Welding Rotator is put onto the working table. This is for the purpose of ideal ergonomics condition--- That operator can have a comfortable position to manage the welding process, during running of the Welding Center: (Fig.1)

4) Welding Ballast: The smaller and thicker pipe inside the stainless steel workpiece serves as ballast, for operation. Please check the below figure: (Fig.2)

5) PPE (Personnel Protection Equipment): Also can be found from the above photo, the GMAW, or gas shielded welding process emits arc light, which do harm on people’s eyes. So, welding face shield is used even in automatic welding of this Welding Integrated Station: Operator needs to manipulate and surveillance welding process.

4. Welding Torch Management in Welding Manipulator and High Precision GMAW Welding Center:

1) Welding torch is fit on the front end of horizontal boom;

2) The Leadscrew Adjusting Welding Rotator serves as holding unit and rotation of the workpiece;

3) Welding Seam tracker is usually for controlling on welding process of thick wall workpiece (thickness above 12mm), which involves several passes of welding. Because in this Light duty Welding Center, it is for fabricating on thin wall workpiece (Maximum thickness is 10mm), and needs only 1~2 passes of welding, seam tracker is not necessary for Welding Manipulator;

4) Internal Welding: This group of convenient Welding Center can be used for internal welding also. For this purpose, horizontal boom needs to be lowered down to the same level as circle center of the workpiece, which is laid on the Leadscrew Adjusting Welding Rotator, and extended into the workpiece for performing welding process;

5. Welding Technique Adopted in the High Precision GMAW Welding Center:

1) Material of stainless steel and thin thickness of the workpiece calls for stricter demand on precision control;

2) Besides the design and manufacture of mechanical system of this Welding Integrated Station, the GMAW welding power supply applied also has several technical features to meet the demand;

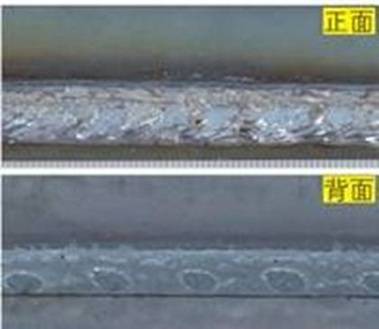

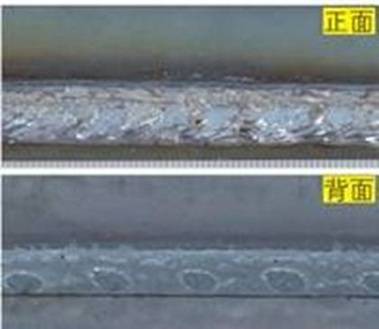

3) For example, the Pulse constant arc length control---ALC (Arc Length Consistence) as below: (Fig.3,4)

4) This means with the changing wire extending length (within the range of 10~ 30mm), the arc length is kept at a constant value in the welding process of this High Precision GMAW Welding Center;

5) It is realized with the pulse parameters of welding power supply in the Welding Manipulator, and improves on dynamic characteristics and arc stability greatly, which in turn guarantees welding quality to the maximum degree, and thus reduces welding defect to the minimum level;

6) Operation and maintenance of this High Precision GMAW Welding Center involves one operator only. For the Welding Manipulator and Leadscrew Adjusting Welding Rotator itself, we have operating panel on the control board and a remote pendant (see attached pictures); For the GMAW welding power supply, it is equipped with console for management. See below photo: (Fig.5)