A. Usage and Application of the United Working SXBJ-4 Steel Plate Edge Milling Machine:

1. Usage of the Combined SXBJ-4 Sheet Metal Plate Beveling Machine:

1) This combined equipment is for milling on welding grooves on upper/ Straight/ Lower edges of steel plate, and at its both ends edges;

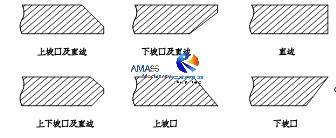

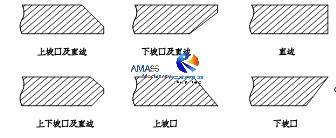

2) Typical types of welding grooves milled from SXBJ-4 model machine: (Fig.1)

2. Application of SXBJ-4 Steel Plate Edge Grooving Machine:

1) As can be seen from the attached first photo and below, such kind of united working SXBJ-4 tandem machine is applied in a large scale automatic production line;

2) This is the reason why the Edge Milling Machine has max. effective stroke of 4000 mm, the “standard” specification for automatic equipment deployed in a production line;

3) The other perspective on the view of combined SXBJ-4 tandem machine: (Fig.2)

3. Equipment Applied in the Production Line together with the SXBJ-4 Steel Plate Edge Milling Machine:

1) For this specific business case, besides Edge Milling Machine, there are other Welding and Cutting equipment produced by Wuxi JACK in the same Production Line:

a) At the beginning of the Production Line: CNC CG4000 CNC Strip Cutting Machine, the 1st operation equipment for performing steel plate cutting off;

b) At the middle section of the Production Line: RH3000 Edge Rounding Machine, for deburring and rounding ribbed plate element;

c) At the end section of the Production Line: J28 Ribbed Plate Element Straightening Machine;

2) All of these equipment are painted in the same color as the united working SXBJ-4 tandem machine;

3) The final product of the production line is large size square cross section beams, for producing Port Machinery.

B. Configuration and On Site Arrangement on the SXBJ-4 Steel Plate Edge Milling Machine:

The design and development on such tailor made SXBJ-4 tandem machine focus on meeting customer demand and application scenario:

1. Demand on the Application Scenario of the Steel Plate Edge Grooving Machine:

1) In this business case, both ends of steel plate need to be beveled, during its going through the entire Production Line, processed from raw material into a final finished product, without midway turning back;

2) For this reason, the steel plates should be edge milled at its both ends with one time passing through the SXBJ-4 tandem machine;

2. For this Purpose, the Steel Plate Edge Milling Machine should Meet the Demand of:

1) It should be double heads model, so that upper/ straight/ lower edges grooving on workpieces can be made with one time stroke of milling heads;

2) There should be 2 sets of SXBJ-14 (Tandem) in the production line. One set is responsible for one end of the workpiece steel plate;

3. Correspondingly, the Requirement on Layout of the Steel Plate Edge Beveling Equipment:

1) For this purpose, the SXBJ-4 tandem machine should be installed in the orientation of “Back to Back”, this means the material inlet and outlet side of the machine group should be at external side of the working zone;

2) Correspondingly, the operating side of the two sets of Edge Milling Machine should be “Face to face”, at the internal side of the working zone;

3) At the internal zone of the tandem machine, there should be conveyors for sending the steel plate going through the area, which does not impose conflict with edge milling carriages of the tandem machine;

4) For this purpose, the internal conveyors between the tandem machine should be capable of swing 0°~ 180°, flexible on its performance and leaving space at the same time:

5) View on Internal Zone: the 0°~ 180° Flipping Roller Table Conveyor, and operating side of the tandem Steel Plate Edge Milling Machine: (Fig.3)

4. Special Requirement on the SXBJ-4 Sheet Metal Plate Beveling Machine:

1) As can be viewed from below photo, the tandem machine are installed inside a pit. This is for the purpose of getting same horizontal level as that of remaining equipment in the Production Line;

2) There are proximity switches installed at the inlet and outlet side of the tandem machine, for detecting on approaching and leaving of workpiece steel plate, so as to be convenient for initiating and shutting off operation in the working zone;

3) The entire working zone of the SXBJ-4 tandem Steel Plate Edge Milling Machine is installed in a workshop pit: (Fig.4)

5. Technical Requirement on Each Set of the SXBJ-4 Steel Plate Edge Milling Machine:

1) For the detailed introduction on each set of the machine, please check product section SXBJ-4 Touch Screen Steel Plate Edge Milling Machine;

2) Operating Side of the SXBJ-4:(Fig.5)

6. Conclusion on the SXBJ-4 United Working Steel Plate Edge Grooving Machine:

1) In a highly effective and sophisticated fabrication line for Shipbuilding and Port Machinery here, productivity is one of the foremost factors to be considered;

2) So, with such deployment of the SXBJ-4 tandem Edge Milling Machine, compromise is made for meeting TAKT time of the Production Line, benefitting from our ingenious design, instead of just one set as in the case of majority conditions.

C. Technical Parameters of United Working SXBJ-4 Steel Plate Edge Milling Machine:

Model Technical Parameter | United Working SXBJ-4 Double Heads Steel Plate Edge Milling Machine |

Max. Plate Edge Milling Length | 4,000 mm/ Set |

Power and rpm of Milling Head | 7.5 kW, 1440 rpm / Set |

Spindle rpm of Edge Milling Head | 75 ~ 420 r/min., 6 grades by handwheel / Set |

Hydraulic Power Motor | 5.5 kW / Set |

Milling Unit Feeding Motor | 2.2 kW / Set |

Milling Head Quantity | 2 sets/ Set |

Plate thickness for Sheet Metal Chamfering | 6∼50 mm (On customer demand) / Set |

Milling Angle of Top Milling Unit | 0° to +80°/ Set |

Milling Angle of Down Milling Unit | -45° to 0°/ Set |

Edge Milling Speed | 130∼1000 mm/min. (VFD, Inverter Control)/ Set |

High Speed of Idle | 4000 mm/min. / Set |

Applicable Diameter of Facer Plate | D=Ø125 ~ Ø320mm (Ø200 For delivery) / Set |

Quantity of Hydraulic Jacks | 9 pieces / Set |

Hydraulic Rated Pressure | 5.5 MPa / Set |

Hydraulic Working Pressure | 3.5 MPa / Set |

Hydraulic System Flowrate | 47 L/min. / Set |

Worktable Width | 450 mm / Set |

Worktable Height | 1050 mm / Set |