A. The Function and Specialty of CP5-2000/6 Heavy duty Flame CNC Pipe Intersection Cutting Machine:

1. Function: CP5-2000/6 is a tailor made model of CNC Pipe Cutting Machine. Its model refers to that, this 5 CNC control Axis CNC Pipe Intersect Cut Equipment can cut and bevel workpiece with diameter up to Φ2000mm, and length 6m;

2. Specialty: It is not a common used model. Generally speaking, the larger the diameter of pipe, the longer the length. So, Heavy duty CNC Pipe Cutting Machine usually have valid horizonal cutting stroke of 9m~ 12m;

3. Meaning: Meanwhile, when customers produce pipe/tanks with length not exceeding 6m, this model of CP5-2000/6 Heavy duty CNC Pipe Intersect Cut Equipment is a good choice: It can not only save investment budget 10~20%, but also occupy much less floor area in customer workshop, which is very important for on site layout arrangement of production line involving CNC Pipe Cutting Machine.

B. The Cutting and Beveling Technique in CP5-2000/6 Heavy duty Flame CNC Pipe Cutting Machine:

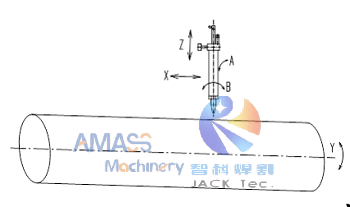

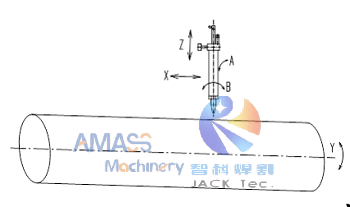

1. The 5 Axis Control in Heavy duty CNC Pipe Intersection Cutting Machine: (Fig.1)

As shown in the above sketch, the X/Y/Z/A/B axis in CNC Pipe Cutting Machine realizes cutting torch movement along the 3D direction for cut off, as well as tilting and 360° swiveling for beveling;

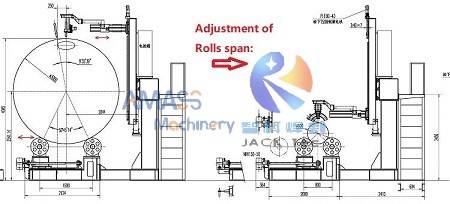

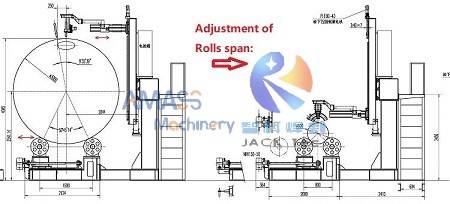

2. Compared with 7 Axis series Heavy duty CNC Pipe Cutting Machine, the 2 axis short in 5 Axis model CNC Pipe Cutting Machine is V axis for lateral movement of cutting torch, and W axis for lateral movement of friction support rollers: (Fig.2)

1) So, in 5 axis CNC Pipe Intersection Cutting Machine, positioning along periphery of pipes is by means of Y axis commanding pipe rotation;

2) The finished workpiece delivered from Wuxi JACK Flame CNC Pipe Intersect Cut Equipment: (Fig.3)

3. Applicable Cutting Way in CNC Pipe Cutting Machine:

1) In theory, both Oxy-fuel flame cutting and plasma cutting can be applied in CP series CNC Pipe Cutting Machine;

2) In practical application, considering pipe wall thickness/ cutting cost/ cutting requirement, Oxy-fuel flame cutting is applicable for all ranges, from light duty to Heavy duty CNC Pipe Intersection Cutting Machine, including this 5 Axis 2000/6;

3) And plasma cutting is more applicable for small to medium duty, such as CP5-600 series CNC Pipe Cutting Machine;

4) The Oxy-fuel cutting in Wuxi JACK Flame CNC Pipe Intersection Cutting Machine: (Fig.4)

C. Operating Tips of CP5-2000/6 Heavy duty CNC Pipe Intersection Cutting Machine:

As a kind of Heavy duty CNC Pipe Intersect Cut Equipment, the CP5-2000/6 CNC Pipe Cutting Machine needs several assistant tools for its smooth running. Examples are as below but not limited to: (Fig.5)

1. Hoist tools for Workpiece Pipe in Heavy duty CNC Pipe Cutting Machine:

1) Due to its usual large size, heavy weight and round shape of pipe, need to take special precaution on loading and unloading onto and off the CNC Pipe Intersection Cutting Machine;

2) A suggestion is slings of rope: Wire rope for heavier pipes, and nylon rope for lighter pipes;

2. Double ladder for Checking Large Pipe of the Heavy duty CNC Pipe Intersection Cutting Machine:

1) Sometimes it is necessary to have inspection or operation on the top section of large pipe, when it is still laid on the CNC Pipe Cutting Machine;

2) By this condition a double ladder is a good choice.

D. Technical Parameters of CP5-2000/6 Heavy duty CNC Pipe Cutting Machine:

Below is specification of 5 Axis 2000/6 Flame Heavy duty CNC Pipe Intersect Cut Equipment:

Model Technical Parameter | 5 Axis CNC-CP 2000/6 Heavy duty Flame CNC Pipe Intersection Cutting Machine |

Fitting Diameter Scope of Pipe (mm) | 400 ~ 2000 |

Fitting Max. Length of Pipe (mm) | 6000 |

Fitting Thickness Scope of Pipe (mm) | 6~100 mm for flame cutting; 3 ~ 25mm for plasma cutting |

Fitting Cutting Speed | 200∼800mm/min. for flame cutting Around 200~ 2000mm/min. for plasma cutting (Based on thickness of Pipe and Plasma Power) |

Valid CNC Control Axis | 5 Axis of X/Y/Z/A/B X Axis: For cutting torch positioning along pipe length Y Axis: For pipe rotation; Z Axis: For cutting torch lift and descend; A Axis: For swiveling cutting torch along workpiece radius; B Axis: For swiveling cutting torch along pipe length |