Finished Workpiece of Z20 H Beam Assembly Machine:

As you can find from the first photo, this set of H Beam Production Machine Z20 Automatic control H Beam Assembly Machine was producing a piece of welding T Beam, the half finished product of welding H Beam.

1. Characteristic of Z20 Automatic Control H Beam Assembly and Tack Welding Machine:

1) "High End" Z20 H Beam Assembly and Tack Welding Machine:

The Z20 Self Alignment Automatic control I Beam Assembly Machine is the High End product of its kind, because of the below factors:

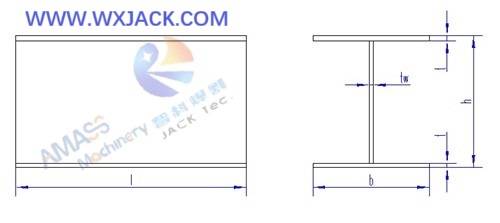

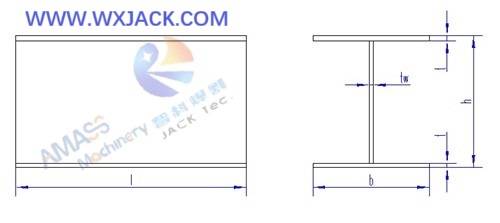

a) The largest H Beam assembled and tack welded from the Z20 I Beam Assembly Machine: Web height h of the produced H Beam can be up to 2000mm:

Sketch of H Beam to be assembled from Z20 I H Beam Assembly Machine: (Fig.1)

b) Central Working Unit: The advanced configuration for the function unit of flange and web self alignment, as well as automatic CO2 welding power supply in the H Beam Assembly Machine:

Electric control board of Z models I Beam Assembly and Tack Welding Machine: (Fig.2)

CO2 welding power supply to be equipped with H Beam Assembly and Tack Welding Machine: (Fig.3)

2) Commercial Offer on Z20 I H Beam Assembly Machine:

Hence forth, price of the Z20 self alignment Automatic control I Beam Assembly Machine with automatic tack welding is the highest among the product group of Z series H Beam Assembly Machine. To be specifically,

a) Max. H Beam Size: Taking other configurations all the same for the machine, Z20 H Beam Assembly Machine has around 4% higher quotation than Z15;

b) Assembly Control Mode: Taking other configurations all the same for the machine, Self Alignment assembling type automatic H Beam Assembly Machine has around 8% higher quotation than Manual Alignment assembling type H Beam Assembly Machine;

c) Welding Mode: Taking other configurations all the same for the Z series H Beam Assembly and Tack Welding Machine, the configuration of automatic spot CO2 weld has around 10% higher quotation than Manual CO2 Weld;

3) Summing up, the Z20 self alignment Automatic control H Beam Assembly and Tack Welding Machine is 22%~25% more expensive than the Z15 I Beam Assembly Machine manual alignment with manual CO2 welding.

2. The Benefits with the Z20 Self Alignment H Beam Assembly machine with Automated Tack Welding:

On the other hand, the strong points with the H Beam Production Machine Z20 Automatic control I Beam Assembly and Tack Welding Machine are:

1) High Efficiency: Quicker and easier work on alignment of flange and web for operator. Therefore, less cycle time of the H Beam Assembly and Tack Welding Machine accordingly;

2) Superior Tack Welding Quality: Consistent and stable CO2 tack welding quality of workpiece delivered from the automatic H Beam Assembly Machine compared with manual job;

3) Flexible Operating Manner: Flexible multiple choices on working style of the machine for CO2 welding speed, length and interval of welding seam:

View on assembling and tack welding in I Beam Assembly and Tack Welding Machine: (Fig.4)

4) Proper Models Choice: So, for the specific configuration of the Z series I Beam Assembly and Tack Welding Machine, the choice between assembling style of Self alignment versus Manual alignment, and Automatic versus Manual spot CO2 weld is compromise for customer of the H Beam Assembly Machine, depending on your preference and which factor gains more weight.

3. Application Field of Z20 Automatic control H Beam Assembly Machine with Automatic CO2 Tack Welding:

1) Where Used: Another complement is the H Beam Production Machine of Z20 is the H Beam Assembly and Tack Welding Machine used in “Heavy duty Automatic H Beam Production Line” of H Beam due to its largest specification;

2) Which Model is more Proper: Z20 H Beam Assembly Machine can cover welding H Beam of delivery from Z15 and Z18 Automatic control I Beam Assembly Machine. But if most majority of workpiece fall within the scope of 1500mm and or 1800mm web height, Z15 H Beam Assembly Machine or Z18 is better choice considering the factor of cost efficiency;

3) In All, the selection on Z20 Automatic control H Beam Assembly Machine is determined by how much percentage of H Beam at customer site have web width in the range of 1800~2000mm.

4. Technical Parameters of Z20 Automatic control H Beam Assembly Machine:

Below are specifications of this Z20 Self Alignment Automatic control H Beam Assembly and Tack Welding Machine:

Model | Z20 Self Alignment Automatic control I Beam Assembly Machine with Automatic Tack Welding |

Max. H Beam Web Height (mm) | 2000 |

Scope of H Beam Web Thickness (mm) | 6∽32 |

Scope of H Beam Flange Width (mm) | 200∽800 |

Scope of H Beam Flange Thickness (mm) | 6∽40 |

Scope of H Beam Length (mm) | 4000∽12000 |

Max. H Beam Weight | 20 Ton. |

Power of Input and Output Conveyor | 1.1 kW x 2 |

Power of Hydraulic Motor | 4 kW |

Length of Input and Output Conveyor | 2600 x 3 mm |

Assembling and Tack Welding Speed | 0.5 ~ 6 m/min., Continuous Adjusting |

Web and Flange Alignment Style | Self Alignment Automatic Assembling |

Tack Welding Style | Automatic CO2 tack welding controlled with PLC |