A. The Criterion on Dividing Standard Sheet Metal Plate Edge Milling Machine:

There are many dimensions to classify on sheet metal plate Welding Groove Maker Edge Milling Equipment:

1. Based on Milling Head Configuration and Productivity of Plate Edge Chamfering Machine:

1) Single head configuration XBJ series Machine for plate end beveling;

2) Double heads configuration SXBJ series machine of plate edge milling;

3) Four or five heads configuration FXBJ and GFXBJ series machine for plate edge milling;

2. Based on Edge Milling Stroke of the Sheet Metal Plate Welding Groove Maker:

1) Small plate edge milling size and stroke machines: The corresponding max. effective edge milling stroke range is from 3,000mm to 6,000mm;

2) Medium plate edge milling size and stroke machine: 6,000mm to 12,000mm;

3) Large plate edge milling size and stroke machine: 12,000mm to 23,000mm;

3. Based on Design on the Sheet Metal Plate End Beveling Machine:

1) Standard design Edge Milling Equipment on sheet metal plate of this product section;

2) Special design tailor made machines for edge milling on sheet metal plate.

B. Scope and Application of Standard Sheet Metal Plate Welding Groove Maker:

1. What is Standard Sheet Metal Plate Edge Chamfering Machine?

1) Structure:

a) Mechanical main body of the standard structure machine for edge milling is open style stationary gantry and working table frame;

b) The front side of the standard plate Welding Groove Maker mechanical frame is for workpiece loading in and out;

c) The rear side of the standard plate Edge Chamfering Machine mechanical frame is installed with one or two sets of milling heads, for performing edge grooving task;

d) Mechanical main frame and operating side of Wuxi JACK XBJ-9 standard model machine: (Fig.1)

e) Workpiece sheet metal plate loading and unloading side of Wuxi JACK SXBJ-15 model standard model Edge Milling Equipment on sheet metal plate: (Fig.2)

2) Milling Head: The 7.5kW, and 6 grades of spindle revolutionary speed adjustable, equipped in the Wuxi JACK standard edge milling model machine: (Fig.3)

3) Function of Standard Sheet Metal Plate Edge Chamfering Machine:

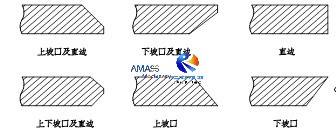

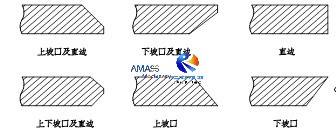

a) Mill out all the types of necessary welding grooves on top and bottom edges of workpieces steel plate, completed in the machine: (Fig.4)

b) The finished straight side groove on edge of steel plate, delivered from Wuxi JACK standard models Sheet Metal Plate End Beveling Machine: (Fig.5)

2. Application of Standard Sheet Metal Plate Welding Groove Maker:

1) In practical application field, standard models machine accounts for over 90% of total business case on edge milling use;

2) Standard models Edge Milling Machine can meet most majority of customers worldwide, covering across industries of wide diversified specific demand.

C. Common Points of Standard Sheet Metal Plate Edge Milling Machine:

So, what implicate on a set of standard models machine for edge chamfering on sheet metal plate?

1. Mechanical System of Standard Plate Welding Groove Maker Edge Milling Equipment:

1) Mechanical main body of the standard models machine has structure of gantry beam integral body, with its top pressing beam installed with a bottom position working table, which stands in fixed position in foundation of this sheet metal plate Welding Groove Maker;

2) Moving milling carriage of the standard models machine is used for installing milling head, and its individual control board, together with related driving and transmission system, by means of an upper position vertical column and lower holding bracket, assembled onto the work table of the sheet metal plate Edge Chamfering Machine;

3) The motorized moving milling carriage of Wuxi JACK XBJ and SXBJ series sheet metal plate End Beveling Machine: (Fig.6)

4) Workpiece Loading: There are front extension supporting racks of 1,000 ~ 3,000 mm length extension, installed into workshop floor, for loading and unloading of workpieces steel plates into and out of the machine before and completion of edge milling operation;

2. Working Units in Plate End Beveling Machine:

1) Milling Heads to be Used in Standard Model Machine:

a) One or two sets of milling cutter, which is usually 7.5kW adopted in Wuxi JACK conventional standard models machine;

b) This can be compared with 5.5kW milling head equipped in many same trades in market, depending on expected finished bevels and chamfers to be made;

2) Guideway installed in the Plate Edge Milling Equipment:

There are 2 units of horizontal guideway assembled in each set of Edge Milling Machine:

a) The top level one is precise linear guideway, which is assembled onto mechanical base bed of machine by means of bolts, in the detachable style;

b) In the case of heavy duty machine: 19m and plus edge milling stroke of sheet metal edge milling length, for workpieces up to 100mm thickness and 70s ton weight, this piece of guiderail is of heavy loading type;

c) The bottom level one is assembled in flat position, which means parallel with ground surface of the machine for fulfilling edge milling task;

d) The double stages of horizontal guiderails, assembled in Wuxi JACK plate Edge Milling Machine: (Fig.7)

e) Such double arrangement of horizontal guiderail, guarantees on the best degree precision and stability of metal plate chamfering job for producing welding groove, in the plate Welding Groove Maker machine;

3. Hydraulic System of Plate Edge Chamfering Machine:

During edge milling work in the machine:

1) Because of the large size and heavy weight of workpiece steel plates to be processed in Edge Milling Machine, as well as operation of high speed steel plate beveling operation;

2) The workpiece steel plates should be secured firmly into working table of the machine, this is realized by means of a line of hydraulic drive jacks;

3) Hydraulic oil cylinder drive jacks installed in Wuxi JACK machines for edge milling on sheet metal plate, pressing workpiece firmly during running: (Fig.8)

4) Quantity of these hydraulic drive jacks is determined by the max. valid edge milling stroke of Welding Groove Maker machine (plate length).

D. Technical Parameters of Standard Sheet Metal Plate Edge Milling Machine:

Model Technical Parameter | Standard Structure XBJ and SXBJ Series Sheet Metal Plate End Beveling Machine |

Max. Sheet Metal Plate Edge Milling Stroke | 3,000 ~ 18,000 mm;

|

Sheet Metal Plate Width Range | 600 mm to 3,000 mm |

Sheet Metal Plate Thickness Range for Edge Groove Making | 6 ∼ 100 mm (Based on customer demand) |

Models of Edge Milling Machine | XBJ/ SXBJ-3 to SXBJ-18 |

Power and rpm of Lengthways Milling Head | 7.5kW, 6 grades velocity change by handwheel |

Hydraulic Power Motor | 7.5 kW |

Taper Hole of Milling Spindle End | ISO 50 (7:24) |

Milling Head Quantity | 1 or 2 sets |

Milling Angle Range of Top Milling Unit | 0° to +60° |

Milling Angle Range of Down Milling Unit | -45° to 0° |

Lengthways Edge Milling Speed | 150~ 1000 mm/min. VFD A.C. Inverter |

Idle High Speed | Constant 4000 mm/min. |

Diameter of Longitudinal Facer Plate | Ø200 mm or Ø315 mm |

Quantity of Hydraulic Pressing Jacks | 6 ~ 27 Pieces (Based on max. edge milling stroke of the model) |

Worktable Width | 450~ 550 mm |

Worktable Height | 1050 mm |