A. Usage and Main Action of LH50 Cylinder Longitudinal and Annular Seam Welding Machine:

1. Main Function: This Cylinder Welding Equipment is for fulfilling welding of both annular seam and longitudinal seam on balloon workpieces, or cylindrical working parts;

2. Welding mode is by means of SAW welding (Submerged arc welding):

SAW carried out in Longitudinal and Annular Seam Cylinder Welding Equipment: (Fig.1)

3. This Longitudinal and Annular Seam Cylinder Welding Machine can accomplish the actions of:

Referring to photo as below:

LH50 Cylinder Annular and Longitudinal Seam Welding Machine indication: (Fig.2)

1) Cylinder Length Adjustment: The mechanical moving side of the Cylinder Welding Machine can move forward and backward, catering on different lengths of balloon working parts;

2) Annular Welding: Revolve the secured pipes under required and adjustable welding linear speed, for welding the annular seam --- Working as cylinder Annular Seam Welding Machine;

3) Longitudinal Welding: The welding torch moves in adjustable welding speed, along length direction of barrel body, for welding the longitude seam --- Working as cylinder Longitudinal Seam Welding Machine;

4) Secure Workpieces: The mechanical moving side of the Cylinder Welding Machine can press end of the balloon by means of hand wheel, along axis direction of the balloon workpieces;

5) Workpiece Revolve: The fixed side can drive the balloon workpiece into speed adjustable rotation, by means of one piece of three jaw chuck to clamp the balloon, which is installed at operating side of the Cylinder Welding Equipment.

B. Structure and Technical Performance of LH50 Longitudinal and Annular Seam Cylinder Welding Machine:

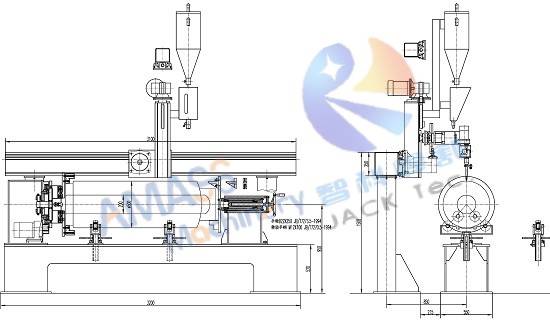

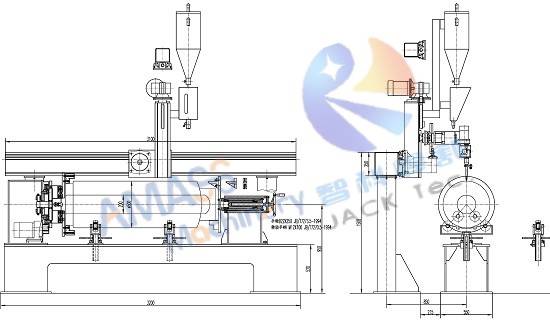

Mechanical structure design drawing of the LH50 Cylinder Welding Equipment: (Fig.3)

It has something in common with CNC Pipe Cutting Machine:

1. Mechanical Frame of the Cylinder Longitudinal and Annular Seam Welding Machine:

1) This unit is the base bed for fixing the workpiece rotating and driving unit;

2) The other side is motor drive moving unit;

3) There are two sets of supporting rackets fixed with mechanical frame of the Annular and Longitudinal Seam Welding Machine;

4) This mechanical frame is welding structure member, which is machined precisely after welding and annealing;

5) It has high strength and anti-impact performance, guaranteeing long term stable running of the Cylinder Welding Machine;

2. Welding Torch Adjusting Unit of Cylinder Annular and Longitudinal Seam Welding Machine:

1) Purpose: This unit is for driving welding torch movement along workpieces balloon longitudinal direction;

2) Horizontal Movement: Its driving is adopted with gear reducer and motor. Moving speed is adjusted with A.C. inverter;

3) Vertical Movement: Welding torch is lifted up and descended down thru reducer and motor, depending on varying diameter of workpieces being secured in the Cylinder Welding Machine;

4) Precise Position Control: Have one set of 3 dimensional adjusting unit for managing welding torch position, to make sure welding torch aiming on the welding seam all the while, during operation of the Cylinder Welding Machine;

5)The welding torch manipulating unit in LH50 Longitudinal and Annular Seam Cylinder Welding Machine: (Fig.4)

3. Revolving Mechanism in Cylinder Longitudinal and Annular Seam Cylinder Welding Equipment:

1) Revolving linear velocity is controlled with A.C. inverter, making the speed controllable continuously and stepless;

2) Revolving Transmission Chain Mechanism: Revolving driving motor → gear reducer → rotary support → three jaws chuck → Workpiece revolving, in the Annular Seam Welding Machine;

4. Longitudinal Moving Unit in Cylinder Longitudinal Seam Welding Machine:

1) Function: According to different length of workpieces balloon, this unit moves to suit end position of workpiece, and fix the workpieces with bolts;

2) Working Style: After the balloon is clamped, turn the hand wheel, to make the T type screw to clamp the balloon firmly into the Cylinder Welding Equipment;

3) There is one piece of disk, and fixed with jack catch, to clamp the balloon of the Cylinder Welding Equipment;

5. Conductive Device of the Longitudinal and Annular Seam Cylinder Welding Machine:

1) There is conductive device installed on revolving worktable, thus forming the conductive circuit for welding operation;

2) The conductive capacity is 1000A;

6. SAW Welding System of the Longitudinal and Annular Seam Cylinder Welding Equipment:

1) Use HUAYUAN made ZD7-1000IGBT welding power source and control panel;

2) Equipped with one set of SAW welding wire feeder;

3) The SAW welding source is placed on the ground;

4) Its control panel is installed onto horizontal beam of the Cylinder Welding Machine;

5) Wire feeder is installed onto moving carriage, and moves along with welding torch of the Longitudinal and Annular Seam Welding Machine;

7. Welding Flux Recovery of Longitudinal and Annular Seam Cylinder Welding Machine:

1) Equipped with one set of welding flux recovery system;

2) The motor power is 3.0kW;

3) Welding flux loading capacity is 100kg.

C. Supply Range of LH50 Longitudinal and Annular Seam Cylinder Welding Equipment:

1. Main Body of the Cylinder Longitudinal and Annular Seam Welding Machine:

Including:

1) Stationary mechanical base bed, 1 set;

2) Horizontal beam and working table, 1 set;

3) Workpiece rotating driving unit, 1 set;

4) Moving and idle rotate unit, 1 set each;

5) 2 set of supporting rackets;

6) Welding torch move beam and drive unit, 1 set each;

7) Welding torch 3 dimensional adjusting unit, 1 set;

2. Welding System of the Cylinder Annular and Longitudinal Seam Welding Machine:

Including one each set of:

1) HUAYUAN ZD7-1000IGBT welding source;

2) Wire feeder and control panel;

3) Welding flux feeding and recovery unit;

3. Electric Control System of the Cylinder Longitudinal and Annular Seam Welding Machine;

4. Technical Documents of the Cylinder Annular and Longitudinal Seam Welding Machine:

1) Quality Certificate;

2) Packing List;

3) Manual Book;

4) Electric Diagram;

5) Foundation Drawing.

D. Technical Parameters of LH50 Cylinder Longitudinal and Annular Seam Welding Machine:

No. | Parameter | Specification | Note |

1 | Applicable Balloon Diameter | Φ200 mm ~Φ500 mm |

|

2 | Applicable Balloon Length | 300 mm ~1600 mm |

|

3 | Rotate Linear Speed (Welding Speed) | 100-1000 mm/min. | Inverter control, continuous stepless adjustment |

4 | Welding Torch Moving Speed | 100-1000 mm/min. | At longitude direction |

5 | Rotating Drive Motor | 400 W |

|

6 | Longitudinal Moving Motor | 400 W |

|

7 | Welding Torch Vertical Lift Motor | 200 W |

|

8 | Rotate Support Unit | 2 sets | Manual adjust height |

9 | SAW Power Source | ZD7-1000IGBT | China HUAYUAN |

10 | Welding Flux Recovery | 1 set, 3.0 kW | 100kg welding flux |

11 | Max. Welding Current | 1000 A | Max. Welding Ground Current |

12 | Welding Torch Adjust Unit | 1 set, 3 dimensional | About 100mm stroke |

13 | Rotating side Three Jaw Chuck | 1 set, clamp the balloon |

|

14 | Total Power | Main machine 4.0 kW SAW is 65.0 kVA |

|

15 | Power Electricity | AC380V,50Hz,3P |

|