A. The General Background on SXBJ-125 Large Steel Plate Welding Groove Edge Milling Machine:

1. The attached photos reflect on installation, assembling and validation of the Wuxi JACK SXBJ-125 model special made machine for end milling on large steel plate ;

2. Customer: This set of Welding Groove End Beveling Machine is developed by Wuxi JACK for a Russian company from Ship Building industry;

3. What’s Difference with this Special Made SXBJ-125 Large Steel Plate End Beveling Machine:

There are some newly adopted functions embedded in this large machine, including:

1) Wider range of milling angle tilting for adjusting finished grooves;

2) Precise management and display on milling angle by means of HMI (Human machine interface);

3) Milling head motorized swing, etc.

Which we will have a brief introduction here in this product section of the machine for edge milling . The main focus is on unique milling angle of the equipment;

4. Purpose of This SXBJ-125 Large Steel Plate Edge Milling Machine:

1) This machine helps customers getting ideal welding grooves of various types on workpieces edges, in the best degree of quality and efficiency:

2) Assembling and testing zone of Wuxi JACK SXBJ-125 Large Steel Plate End Beveling Machine: (Fig.1)

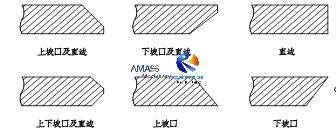

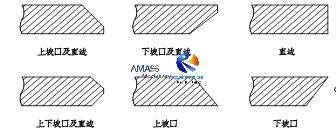

3) The illustration on top/ straight / bottom edge chamfers made from machine: (Fig.2)

4) Working moment of Wuxi JACK SXBJ-125 model large machine of welding groove edge milling and its superior quality grooving: (Fig.3)

B. The Most Distinguished Technical Ability of SXBJ-125 Large Steel Plate Welding Groove End Beveling Machine:

Broader Range of Milling Head Angle Adjustment:

1. In “Ordinary” or Standard models of Double Heads Plate End Milling Machine:

1) This general purpose Edge Milling Machine has one piece of milling head tilted in the range of 0° to 45°, for performing up and straight edge beveling;

2) And the other piece of milling head tilted in the range of -45° to 0°, for performing bottom edge beveling;

3) The milling heads for implementing on upper and straight edge beveling, together with bottom edge beveling in conventional Welding Groove End Beveling Machine: (Fig.4,5)

2. Comparatively, in this set of custom made SXBJ-125 Large Steel Plate Edge Milling Machine:

1) Both sets of the milling head have milling range of -45° to 45°;

2) In other words, you can take it that, every piece of the milling head in this set of machine for welding groove edge milling combines working capacity of the two milling heads in conventional or standard models of the equipment;

3) Fitting up the -45° to 45° swing angle milling head in Wuxi JACK SXBJ-125 Large Steel Plate Edge Milling Machine: (Fig.6)

3. The Added Value of Double Sets -45° to 45° Milling Heads for Customers of SXBJ-125 Welding Groove Edge Milling Machine:

For customer of this machine on plate end beveling, the favorable outcomes brought with these powerful milling heads are:

1) Either set of the milling head in this large machine for edge milling on steel plate can do both top and bottom edges beveling on workpiece steel plates;

2) In other words, you can draw conclusion that, every set of the milling head in this set of large machine integrates working capability of the two milling heads, in “ordinary” or standard model of the equipment;

3) Please check the attached second photo and below, for viewing on the two sets of milling heads stopped together in this SXBJ-125 Advanced Configuration Edge Milling Machine:

4) The installation orientation of the 2 sets of A.C. motors, for driving tilting of the 2 pieces of milling heads, in the Wuxi JACK SXBJ-125 special made Large Steel Plate End Milling Machine: (Fig.7)

5) You can identify from the above photo that, both sets of milling heads are in the position for carrying out bottom edge beveling, which is different from conventional types of double heads long stroke Edge Milling Machine.

C. Productivity Analysis on SXBJ-125 Special Made Large Steel Plate Welding Groove Edge Milling Machine:

i. Applicating Scenario Supposed: Talking on everyday application of the XBJ and SXBJ series Edge Milling Machine, suppose customers plan to make both top, straight and bottom edges beveling on their workpieces, let us make comparison on the three scenarios, by means of the three types of Welding Groove End Beveling Machine as below:

ii. Topic: How to fulfil outcome of top, straight and bottom edges beveling in Plate End Beveling Machine?

1. Single Head Configuration Welding Groove Edge Milling Machine:

1) In XBJ models single head machine for sheet metal edge milling, the workpiece steel plates need to be loaded off and loaded into the machine work table two times;

2) Together with one time of workpiece 180° overturning, for completing on first top edge and then bottom edge beveling on edges of workpiece;

2. Conventional Double Heads Welding Groove Edge Milling Machine:

1) In “ordinary” or standard models of double heads machine for plate edge milling, customers can use the piece of (0° to 45°) milling head for implementing on top and straight edge beveling;

2) And the other piece of (-45° to 0°) milling head for implementing on bottom edge beveling;

3) Meanwhile, the tasks of the two main heads in conventional double heads machine can not be exchanged;

4) For this reason, the two pieces of milling heads should be driven back and forth along work table of the machine of edge milling, for fulfilling its tasks;

3. This Tailor Made Wider Milling Angle Range Double Heads SXBJ-125 Edge Milling Machine:

1) With this this special made large machine for steel plate edge milling, customers can have both sets of milling heads carrying out top and or bottom edges beveling at the same time;

2) This means that, tasks of the two sets of milling heads can be exchanged during running of the edge milling period in machine, without moving the milling heads back and forth, rendering the best flexibility for machine operation;

3) Please check attached video on checking running moment of this SXBJ-125 Large Steel Plate Edge Milling Machine.

D. Technical Parameters of SXBJ-125 Large Steel Plate Welding Groove Edge Milling Machine:

Model Technical Parameter | -45° to +45° Milling Angle Range SXBJ-125 Double Heads Large Steel Plate Welding Groove End Milling Machine |

Max. Edge Milling Stroke on Workpiece Plate | 12,500 mm |

Workpiece Steel Plate Width Specification | 600mm to 3,000 mm |

Steel Plate Thickness Range for Sheet Metal Edge Chamfering | 6∼160 mm |

Quantity of Hydraulic Drive Clamping Jacks | 21 Pieces |

Edge Milling Head Quantity | 2 Sets |

Tilting Angle Range of Top Milling Unit | -45° to +45° |

Tilting Angle Range of Bottom Milling Unit | 45° to +45° |

Power of Milling Head | 11 kW |

Spindle rpm Scope of Edge Milling Head | 65 ~ 715 r/min., 9 grades by handwheel |

Hydraulic Power Motor | 5.5 kW |

Milling Unit Traveling Motor Power | 2.2 kW |

Milling Unit Lifting Motor Power | 1.1 kW |

Taper Hole of Milling Spindle End | ISO 50(7:24) |

Milling Tilting Angle Management | By HMI |

Milling Tilting Management | A.C. Motor drive and encoder, proximity switch |

Workpiece Handling Way | By hydraulic Roller Conveyor |

Edge Milling Speed | 150∼1000 mm/min. Stepless and Continuous with inverter |

Idle High Speed of Milling Carriages | 4000 mm/min. Constant |

Applicable Diameter of Facer Plate | D=Ø125 ~ Ø320mm (Ø200mm For delivery) |

Quantity of Hydraulic Jack Screw | 8 sets, intermittently installed |

Worktable Length | 18.7 m |

Worktable Width | 550 mm |

Worktable Height | 1050 mm |