1. Purpose of ZHJ8020 Model 3 in 1 H Beam Assembly Welding Straightening Machine:

1) This is the largest model of ZHJ series machine; The Max. Workpiece Size: ZHJ8020 has manufacturing capability of welded H Beam with web (wall) height up to 2,000 mm, in the form of symmetric joint between web and flanges. Please check attached picture and below sketch:

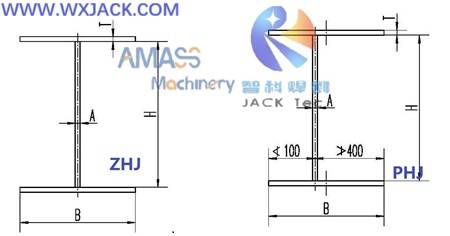

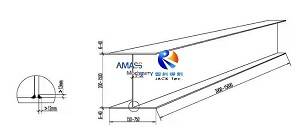

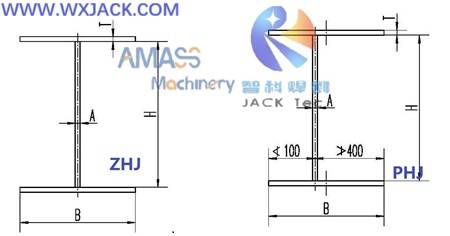

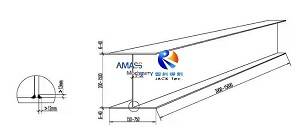

H Beam cross section style produced from ZHJ models machine: (Fig.1)

2) Welding Mode: For producing such big size of workpiece, the welding mode in ZHJ8020 Integral function H Beam Fabrication Machine is SAW (Submerged arc welding).

2. Restriction on Welded H Beam Produced with ZHJ8020 SAW H Beam Fabrication Machine:

Besides size range denoted at end of this section, another requirement on finished product from ZHJ series Integrated function H Beam Welding Machine is:

As one of the preparatory tasks of operating on ZHJ series Vertical H Beam Welder, please make sure specifications of welded H Beam conforms to below rule of thumb on relationship between flange thickness and width that can be straightened with ZHJ series machine:

Flange Thickness T(mm) | 6~20 | 20~25 | 25~32 | 32~40 |

Flange Width B(mm) | 200~800 | 450~800 | 600~800 | 700~800 |

3. Working Units of ZHJ8020 SAW H Beam Fabrication Machine:

1. General Structure of the 3 in 1 H Beam Assembly Welding Straightening Machine:

1) The attached picture shows mechanical main body of a set of ZHJ8020 model machine:

2) Such big height Vertical H Beam Welder is assembled into shape from a vertical gantry and a solid base, with assembling unit, welding torches and straightening rollers fit in sequence;

3) In practical use, there also will be input and output conveyors roller table equipped with the machine;

2. Working Principle of ZHJ Series Integral Function H Beam Welding Machine:

1) Workpiece goes into this Pull Through H Beam Welder from rear side of the mechanical main body and comes out from its front side (Viewed from attached picture);

2) This is also working sequence of H Beam assembling/ welding /straightening arrangement fulfilled in central function zone of the 3 in 1 H Beam machine;

3. Welding Operation in SAW H Beam Fabrication Machine:

1) In conventional H Beam Assembly Machine, both assembling and tack welding (Usually CO2) are performed on workpiece H Beam;

2) Comparatively, in ZHJ series SAW H Beam Fabrication Machine, the workpiece is assembled and then submerged arc welded at the same time;

3) In other words, only the final welding of SAW (Submerged Arc Welding) is implemented in ZHJ series machine: The original CO2 tack welding is removed because of unnecessary in this combined function of 3 in 1 H Beam machine;

4. Transport Unit in ZHJ8020 Integral Function H Beam Welding Machine:

1) This section serves as “Arm” of the 3 in 1 H Beam machine;

2) It includes three segments of input and output conveyor roller table each (totally 10m length each);

3) One piece of motor drive segment and two pieces of idling segments are included into each of the input and output conveyors;

4) For safety purpose, the transmission unit of the Pull Through H Beam Welder input and output conveyors are covered;

5. Hydraulic Pump Station in ZHJ8020 Integral Function H Beam Welding Machine:

1) Task: This unit supplies the “Blood”, or power source to H Beam assembling and straightening units of the machine;

2) Where Used: The assembling unit of manipulators, alignment rollers, and straightening unit of straightening roller are all driven with hydraulic system;

6. Electric Control System of ZHJ8020 Integral Function H Beam Welding Machine:

1) Role: This unit is “Brain” of the machine;

2) Its core elements are A.C. inverter and control relays, controlling motion logic and working speed of the machine respectively;

7) Continuous Improvement: With years of communication and feedback from customers around the globe, from developing stage DFMEA/ PFMEA/ Process Flow/ Control Plan, to mass production stage IQA/ SWS/Periodical Audit, to customer service ECA/Root Cause/PCA, Wuxi JACK has our ZHJ and PHJ series machine in continuous improvement all along, in its design, manufacture and service.

3 core functions in Wuxi JACK 3 in 1 H Beam machine: (Fig.2)

D. Technical Parameters of ZHJ8020 Integral Function H Beam Welding Machine:

Technical Parameter | ZHJ8020 Model 3 in 1 SAW H Beam Fabrication Machine |

Web Height | 200 ∼ 2000 mm |

Web Thickness | 6 ∼ 32 mm |

Flange Width | 150 ∼ 750 mm |

Flange Thickness | 6 ∼ 40 mm |

Workpiece (Welding H Beam) Length | 3000 ∼ 15000mm (At customer demand) |

Working Speed of Assembly/ Welding Straightening | 200∼1200 mm/min.(Continuous, VFD) |

Height of Single Pass Welding Seam | 8~12 mm |

Workpiece (Welding H Beam) Cross Section | Symmetric only |

Machine Overall Dimension(L×W×H) | 28m×4m×4.8m |

Conveyor | Input and Output 10~11m length each |

Driving Mode | Assembly/ Straightening/ Output Conveyor Elevation: Hydraulic; Welding: Electric |

Hydraulic System | 4Kw, 6~8MPa |

Welding Mode | SAW (Submerged Arc Welding, 2.5/3/4 mm diameter welding wire); CO2 Gas Shielded Welding |

Operator | 1 ~ 1.5 (1.5 means a part time support) |