A. Function and Application of Steel Fabrication Auxiliary Sheet Plate Edge Milling Machine:

1. Function of the Steel Fabrication Auxiliary Grooving Equipment End Milling Machine:

1) This branch of compact size model is a kind of general purpose Steel Fabrication Grooving Machine, milling on welding grooves on edges of workpieces sheet plate;

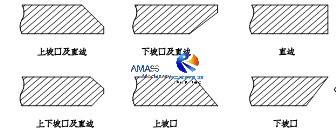

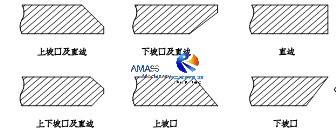

2) The form of welding grooves finished from the machine can be X/ Y/ V/ K... chamfers, etc., on top and bottom edges of workpieces: (Fig.1)

3) The workpieces applicable for this equipment can be sheet metal plates, with length ranging from 1000mm to several meters, such as 6,000mm, which can be designated by customers. Materials of the workpieces can be carbon steel, stainless steel, etc.

2. Application of the Steel Fabrication Auxiliary Edge Beveling Machine:

1) Using Sites: This series of machine is a type of indispensable 1st operation equipment, applied in Steel Structure Facility, Crane Facility, Oil Plant, Chemical, Petrochemical, etc.;

2) Position in Process Route: Steel Fabrication Auxiliary Edge Milling Machine belongs to 1st operation equipment, which is installed at beginning of line in a manufacturing workshop, following CNC Strip Plate Cutting Machine;

3) Value for Customer: By means of completed beveling with certain blunt and chamfer size, such as: X- chamfer (25°-60°, blunt to 2.0 mm) fulfilled from the machine, fully penetration of welding seam can be got on workpieces steel plates, in the subsequent steel fabrication operation:

4) Wuxi JACK SXBJ-4 double heads machine being in operation: (Fig.2)

5) The finished beveled steel plate machined from Wuxi JACK SXBJ-6 Steel Fabrication Auxiliary Grooving Equipment: (Fig.3)

B. Delivery and Working Manner of Steel Fabrication Auxiliary Sheet Plate End Milling Machine:

1. Bevels and Chamfers made with the Steel Fabrication Grooving Machine:

There is no difference on welding grooves made with this series of machine:

1) Assembling Orientation of Milling Heads in Edge Milling Machine:

a) Emphasis here that for double heads machine, the two sets of milling heads are assembled in different orientations:

b) One piece of milling head is for milling on top edge and straight edge chamfers in the machine;

c) The other piece of milling head is for milling on bottom edge chamfers in the machine;

2) Indicating Photos: Please check the attached and below pictures as comparison. The left picture shows the milling head for implementing on upper edge and straight edge chamfers, while the right picture represents the milling head for carrying out lower edge chamfers:

3) The installation orientations of milling heads in double heads machine:(Fig.4,5)

2. Working Style of Steel Fabrication Auxiliary Grooving Equipment:

During edge milling operation:

1) Motion Units: The two pieces of milling heads move in phase, on its individual mounted motorized carriages;

2) Moving Trace: The milling carriages move along long side beveling edge of workpiece steel plate. In other words, machine work table;

3) Traveling Speed: This movement is in the adjustable working speed for edge milling, which is controlled with A.C. inverter, and displayed in real time, on operating pedant of the milling head carriage. Shown in below photo:

4) Working speed adjustment and display in Wuxi JACK Steel Fabrication Auxiliary Grooving Equipment: (Fig.6,7)

5) Fulfilling welding groove making, formed on top and bottom edges of workpieces sheet plates, completed with one time moving stroke of milling heads carriages in the machine.

C. Structure and Main Units of Steel Fabrication Auxiliary Sheet Plate Edge Milling Machine:

1. Structure of the Steel Fabrication Auxiliary End Milling Machine:

1) As can be observed from the attached first and below photo, the XBJ and SXBJ series Steel Fabrication Auxiliary Edge Beveling Machine has open style double sides acting stationary mechanical main frame;

2) The front side is for workpieces sheet plate positioning, by means of hydraulic drive automatic mechanisms;

3) The rear side of machine work table is installed with one or pieces of milling heads and its motorized carriages, shown in below photo:

4) Rear side of Wuxi JACK SXBJ-4 Edge Milling Machine in running: (Fig.8)

2. Edge Milling Head in Edge Beveling Machine:

1) This is the core outsourced component in every machine model;

2) Its spindle rotating speed can be adjusted within the range of 6 grades velocity, denoted in Item 3 technical parameters of this product section, manually adjusted by turning speed lever, on cover of the milling head;

3) The milling head and its convenient way of revolutionary change, equipped in Wuxi JACK Edge Milling Machine: (Fig.9)

4) Wuxi JACK Superiority: Such way of adjustment in Wuxi JACK Edge Milling Machine, is much more superior than competitor’s way of uncovering the spindle box and replacing couple gears, on the aspect of accuracy and convenience;

5) Milling Head Angle Control: Before official running for edge milling, the tilting angle of milling head can be adjusted and displayed precisely, either by way of manual turning, or in the form of motor drive, guaranteeing on accurate finished welding groove angle on edges of workpiece steel plate:

6) Tilting of milling head and its hardware angle indicating ruler, in Wuxi JACK advanced quality Steel Fabrication Grooving Machine Edge Beveling Machine: (Fig.10)

3. Mechanical Bed in Steel Fabrication Auxiliary Edge Milling Machine:

1) Importance: For long stroke model machine, stability and firmness of mechanical bed is especially of vital importance for maintaining on high standard and uniform performance of welding groove machining;

2) Process Technology: The machine mechanical body is fabricated in the process flow of: Welding, heat treatment for backout, high precision machining, and final assembly. The linearity and hardness of integral mechanical body is strictly controlled in the whole manufacturing process of machine production;

3) The Mechanical Main Body of Edge Milling Machine has two major parts of:

a) Top half downward pressing beam and lower half working table;

b) These two pieces of sub-assemblies (The pressing beam and working table) are assembled into one integral mechanical body directly, strengthened with two brackets at its lateral side of machine;

c) In this way, the machine mechanical main body has better degree of stiffness and steadiness.

D. Technical Parameters of Steel Fabrication Edge Milling Machine:

Model Technical Parameter | Metal Plate Edge Beveling Machine

|

Sheet Metal Plate Max. Edge Milling Length, or Stroke | 3,000 mm to 6,000 mm |

Sheet Metal Plate Width Scope | 600 mm to 3,000 mm |

Sheet Metal Plate Thickness Range for Edge Chamfering | 6∼40 / 50/ 80 mm (Based on Customer Demand) |

Quantity of Hydraulic Drive Clamping Jacks | 5 to 10 Pieces |

Edge Milling Head and Carriage Quantity | 1 to 2 Sets |

Milling Angle Range of Upper Milling Unit | 0° to 80° |

Milling Angle Range of Lower Milling Unit | -45° to 0° |

Power and rpm of Milling Head | 7.5 kW, 1440 rpm (Higher Power available) |

Spindle rpm of Edge Milling Head | 75 ~ 420 r/min., 6 grades by handwheel |

Hydraulic Power Motor | 5.5 kW |

Milling Head Spindle Stroke | 100 mm |

Edge Milling Working Speed | 150∼1000 mm/min. Stepless / Set, inverter control and digital display |

Idle High Speed of Milling Unit Carriage | Constant 4000 mm/min. |

Applicable Diameter of Facer Plate | D=Ø125 ~ Ø320mm (Ø200mm For delivery) |

Working Table Width | 450 mm |

Working Table Height | 1050 mm |

Material Handling Style | Conveyor and Roller Manipulator |

Milling Angle Adjustment | Motor Drive and Digital Display |