In this product section we will give a brief introduction on “Big man” of the Edge Milling Machine product family --- The four milling heads equipped within one set of 18,000mm stroke large model.

A. Features and Application of the FXBJ-18 Large Plate Edge Milling Machine:

1. Uniqueness of the FXBJ-18 Large Plate Edge Chamfering Machine:

1) This is up to now the ever biggest and highest grade configured coventional model machine for edge milling, which has gantry structure:

2) This model machine has four sets of 7.5kW milling heads installed on one set, deployed at both sides of the worktable;

3) Of these, two sets of milling heads are assembled at each side of the work table respectively;

2. Total length of the Large Plate End Beveling Equipment body is 30m:

1) This equals to: 18m stroke for edge milling steel plate + 12m length mechanical body for fitting the 4 sets of milling carriages;

2) Width and height of this large model machine mechanical body are also increased accordingly;

3. Usage of the FXBJ-18 Large Plate Edge Milling Machine:

1) This FXBJ-18 is mainly used for milling on small width and long length workpieces: Length of the steel plate is up to 18,000mm, and width up to 1,000mm, which need to have welding groove milling on its both sides, with top/ bottom/ straight bevels made;

2) The classical workpieces clamped on worktable of the FXBJ-18 Large Plate Edge Beveling Machine: (Fig.1)

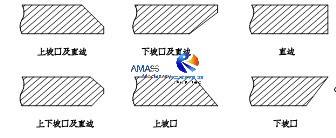

3) The 6 frequently welding grooves that can be milled with the machine: (Fig.2)

4. Application of FXBJ-18 Large Plate End Beveling Equipment:

1) One of the examples of application scenario for this large machine is for making Stiffener Plate Element in Port Machinery;

2) Which, based on design of finished products, are usually made of long slit plates cut from Strip Plate Cutting Machine, then sent to this FXBJ-18 large Edge Milling Machine for milling on welding groove, then welded and straightened in the subsequent work stations;

5. From another perspective, this FXBJ-18 model is the high configured version of “Special made SXBJ-12 Plate Edge Milling Machine” we introduced before:

6. Comparison on FXBJ-18 and SXBJ-12 Large Plate End Milling Machine:

1) The similarity between the two models: The 2 models of the machine all have both sides of the mechanical body installed with milling head, so that both sides of the workpiece can have welding groove being made at the same time;

2) The difference between the two models of the Edge Milling Machine:

a) SXBJ-12 model can only have welding groove milling on top bevels and straight edge of steel plates;

b) The FXBJ-18 large model can have bottom bevels made also, thanks to the configuration of double milling heads at both sides of machine work table.

B. Structure and Performance of the FXBJ-18 Large Plate Edge Milling Machine:

1) This largest model machine shares the same basic structure as the other conventional models. We have taken many spaces in this product family to have introduction. Please refer to the corresponding product sections;

2) As the most sophisticated element in the machine, the two pieces of parallel linear guiderails for guiding movement of the milling carriages, playing vital role in guaranteeing on high precision and consistency of welding groove milling;

3) The installation position of the upper guiderail is vertical, while the lower guiderail is horizontal. Such way of combination promises on the best performance of precision and stability of the machine, compared with single vertical type adopted by other suppliers on the machine.

C. Technical Parameters of FXBJ-18 Large Plate Edge Beveling Machine:

Model Technical Parameter | Four Milling Heads FXBJ-18 Large Plate Edge Milling Machine |

Max. Plate Edge Milling Length | 18,000 mm |

Power and rpm of Milling Head | 7.5 kW, 1440 rpm (Higher Power available) |

Spindle rpm of Edge Milling Head | 75 ~ 420 r/min., 6 grades by handwheel |

Hydraulic Power Motor | 5.5 kW |

Taper Hole of Milling Spindle End | ISO 50(7:24) |

Spindle Stroke | 100 mm |

Milling Head Quantity | 4 sets |

Plate thickness for Sheet Metal chamfering | 6∼80 mm (On customer demand) |

Milling Angle of Top Milling unit | 0° to +45° |

Milling Angle of Down Milling unit | -45° to 0° |

Edge Milling Speed | 150∼1000 mm/min. Stepless |

High Speed of Idle | 4000 mm/min. |

Applicable Diameter of Facer Plate | D=Ø125 ~ Ø320mm (Ø200 For delivery) |

Quantity of Hydraulic Jacks | 30 pieces |

Quantity of Hydraulic Jack Screw | 8 sets, intermittently installed |

Worktable Width | 650 mm |

Worktable Height | 1050 mm |